Abstract

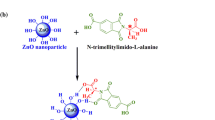

The in situ surface modification of inorganic nanoparticles (NPs) and its influence on the size, morphology, and particle surface properties is increasingly receiving attention. Control of the size and morphology and perfect dispersion of inorganic NPs in polymer matrices fabricates soft materials with unique optical, electrical, magnetic, gas barrier, self-healing, and thermal and mechanical properties. This study explores the strategy of the in situ modification of inorganic NPs (CaCO3) with cationic and anionic surfactants and the role of in situ modification on the dispersion of these NPs in thermoplastic polymers (poly ε-caprolactone, PCL). The surfactants having an appropriate polar head with a high charge density bind onto the crystal’s nuclei, protect them against extensive aggregation, and consequently control the size, morphology, and surface properties of the produced NPs. This permits formulation of hybrid materials with enhanced thermal stability and tensile modulus and with a marked increase of the crystallization rate.

Similar content being viewed by others

References

Kao J, Thorkelsson K, Bai P, Rancatore BJ, Xu T (2013) Toward functional nanocomposites: taking the best of nanoparticles, polymers, and small molecules. Chem Soc Rev 42:2654–2678

Alexandre M, Dubois P (2000) Polymer-layered silicate nanocomposites: preparation, properties and uses of a new class of materials. Mat Sci Eng R 28:1–63

Kongsinlark A, Rempel GL, Prasassarakich P (2012) Synthesis of monodispersed polyisoprene-silica nanoparticles via differential microemulsion polymerization and mechanical properties of polyisoprene nanocomposite. Chem Eng J 193–194:215–226

Oberdisse J (2006) Aggregation of colloidal nanoparticles in polymer matrices. Soft Matter 2:29–36

Kamiya H, Iijima M (2010) Surface modification and characterization for dispersion stability of inorganic nanometer-scaled particles in liquid media. Sci Technol Adv Mater 11:1–7

Zhao LN, Feng JD, Wang ZC (2009) In situ synthesis and modification of calcium carbonate nanoparticles via a bobbling method. Sci China, Ser B 52:924–929

Mihajlović S, Sekulić Ž, Daković A, Vučinić D, Jovanović V, Stojanović J (2009) Surface properties of natural calcite filler treated with stearic acid. Ceram Silik 53:268–275

Garnweitner G (2012) Chapter 4. In-situ versus post-synthetic stabilization of metal oxide nanoparticles, in the delivery of nanoparticles. In: Hashim AA (ed.) InTech. doi: 10.5772/34159. ISBN: 978-953-51-0615-9

Garnweitner G, Ghareeb HO, Grote C (2010) Small-molecule in situ stabilization of TiO2 nanoparticles for the facile preparation of stable colloidal dispersions. Colloids Surf A 372:41–47

Xu AW, Ma YR, Colfen H (2007) Biomimetic mineralization. J Mater Chem 17:415–449

Osman MA, Tallah AA, Suter UW (2004) Influence of excessive filler coating on the tensile properties of LDPE–calcium carbonate composites. Polymer 45:1177–1183

Cai A, Xu X, Pan H, Tao J, Liu R, Tang R, Cho K (2008) Direct synthesis of hollow vaterite nanospheres from amorphous calcium carbonate nanoparticles via phase transformation. J Phys Chem C 112:11324–11330

Morsy FA, El-Sheikh SM, Barhoum A (2014) Nano-silica and SiO2/CaCO3 nanocomposite prepared from semi-burned rice straw ash as modified papermaking fillers. Arab J Chem. doi:10.1016/j.arabjc.2014.11.032

El-Sherbiny S, El-Sheikh SM, Barhoum A (2015) Preparation and modification of nano calcium carbonate filler from waste marble dust and commercial limestone for papermaking wet end application. Powder Technol 279:290–300

Addadi L, Raz S, Weiner S (2003) Taking advantage of disorder: amorphous calcium carbonate and its roles in biomineralization. Adv Mater 15:959–970

Xu XR, Han JT, Cho K (2004) Formation of amorphous calcium carbonate thin films and their role in biomineralization. Chem Mater 16:1740–1746

Gower LB (2008) Biomimetic model systems for investigating the amorphous precursor pathway and its role in biomineralization. Chem Rev 108(2008):4551–4627

Clarkson JR, Price TJ, Adams CJ (1992) Role of metastable phases in the spontaneous precipitation of calcium carbonate. Faraday Trans 88:243–249

Lam RSK, Charnock JM, Lennie A, Meldrum FC (2007) Synthesis-dependant structural variations in amorphous calcium carbonate. CrystEngComm 9:1226–1236

Noel EH, Kim YY, Charnock JM, Meldrum FC (2013) Solid state crystallization of amorphous calcium carbonate nanoparticlesleads to polymorph selectivity. CrystEngComm 15:697–705

Cai GB, Zhao GX, Wang XK (2010) Synthesis of polyacrylic acid stabilized amorphous calcium carbonate nanoparticles and their application for removal of toxic heavy metal ions in water. J Phys Chem C 114:12948–12954

Tobler DJ, Blanco JDR, Dideriksen K, Sand KK, Bovet N, Benning LG, Stipp SLS (2014) The effect of aspartic acid and glycine on amorphous calcium carbonate (ACC) structure, stability and crystallization. Proc Earth Planet Sci 10:143–148

Xu AW, Yu Q, Dong WF, Antonietti M, Cölfen H (2005) Stable amorphous CaCO3 microparticles with hollow spherical superstructures stabilized by phytic acid. Adv Mater 17:2217–2221

Donners JJJM, Heywood BR, Meijer EW, Nolte RJM, Roman C, Schenning APHJ, Sommerdijk NAJM (2009) Amorphous calcium carbonate stabilised by poly(propylene imine) dendrimers. Chem Commun 19:1937–1938

Colfen H, Qi LM (2001) A systematic examination of the morphogenesis of calcium carbonate in the presence of a double-hydrophilic block copolymer. Chem A Euro J 7:106–116

Schaefer DW, Justice RS (2007) How nano are nanocomposites? Macromolecules 40:8501–8517

Barhoum A, Rahier H, Abou-Zaied RE, Rehan M, Dufour T, Hill G, Dufrence A (2014) Effect of cationic and anionic surfactants on the application of calcium carbonate nanoparticles in paper coating. ACS Appl Mater Interfaces 6:2734–2744

Barhoum A, Van Assche G, Maklouf AH, Terryn H, Baert K, Delplancke MP, El-Sheikh SM, Rahier H (2015) A green, simple chemical route for the synthesis of pure nanocalcite crystals. Cryst Growth Des 15:573–580

Tlili MM, Ben Amor M, Gabrielli C, Joiret S, Maurin G, Rousseau P (2001) Characterization of CaCO3 hydrates by micro-raman spectroscopy. J Raman Spectrosc 33:10–16

Meldrum FC, Coelfen H (2008) Controlling mineral morphologies and structures in biological and synthetic systems. Chem Rev 108:4332–4432

Gebauer D, Kellermeier M, Gale JD, Bergström L, Cölfen H (2014) Pre-nucleation clusters as solute precursors in crystallization. Chem Soc Rev 43:2348–2371

Fagerlund J, Highfield J, Zevenhoven R (2012) Kinetics studies on wet and dry gas–solid carbonation of MgO and Mg(OH)2 for CO2 sequestration. RSC Adv 2:10380–10393

Ogino T, Suzuki T, Sawada K (1987) The formation and transformation mechanism of calcium carbonate in water. Geochim Cosmochim Acta 51:2757–2767

Sepulveda L, Cortes J (1985) Ionization degrees and critical micelle concentrations of hexadecyltrimethylammonium and tetradecyltrimethylammonium micelles with different counterion. J Phys Chem 89:5322–5324

Yin WZ, Yang XS, Zhou DP, Li YJ, Lu ZF (2011) Shear hydrophobic flocculation and flotation of ultrafine anshan hematite using sodium oleate. Trans Nonferr Metal Soc 21:652–664

Voss LF, Bazerbashi MF, Beekman CP, Hadad CM, Allen HC (2007) Oxidation of oleic acid at air/liquid interfaces. J Geophys Res Atmos 112:1–9

El-Sheikh SM, Barhoum A, El-Sherbiny S, Morsy F, El-Midany AA, Rahier H (2014) Preparation of superhydrophobic nanocalcite crystals using Box-Behnken design. Arab J Chem. doi:10.1016/j.arabjc.2014.11.003

El-Sheikh SM, El-Sherbiny S, Barhoum A, Deng Y (2013) Effects of cationic surfactant during the precipitation of calcium carbonate nano-particles on their size, morphology, and other characteristics. Colloids Surf A Physicochem Eng Asp 422:44–49

Barhoum A, El-Sheikh SM, Morsy F, El-Sherbiny S, Reniers F, Dufour T, Delplancke MP, Van Assche G, Rahier H (2014) Preparation and characterization of ultra-hydrophobic calcium carbonate nanoparticles. IOP Conf Ser Mate Sci Eng 64:012037. doi:10.1088/1757-899X/64/1/012037

Eskilsson K, Ninham BW, Tiberg F, Yaminsky VV (1999) Effects of adsorption of low-molecular-weight triblock copolymers on interactions between hydrophobic surfaces in water. Langmuir 15:3242–3249

Zhu J, Morgan AB, Lamelas FJ, Wilkie CA (2001) Fire properties of polystyrene−clay nanocomposites. Chem Mater 13:3774–3780

Gilman JW (1999) Flammability and thermal stability studies of polymer layered-silicate (clay) nanocomposites. Appl Clay Sci 15:31–49

Alexandre M, Dubois P (2000) Polymer-layered silicate nanocomposites: preparation, properties and uses of a new class of materials. Mater Sci Eng 28:1–63

Kotsilkova R, Petkova V, Pelovski Y (2001) Thermal analysis of polymer-silicate nanocomposities. J Therm Anal Calorim 64:591–598

Lee J, Takekoshi T, Giannelis EP (1997) Fire retardant polyetherimide nanocomposites. Mater Res Soc Symp Proc 457:513–518

Leszczyńskaa A, Njugunab J, Pielichowskia K, Banerjeec JR (2007) Polymer/montmorillonite nanocomposites with improved thermal properties. Part I: factors influencing thermal stability and mechanisms of thermal stability improvement. Thermochim Acta 453:75–96

Acknowledgements

The present study is a part of Ahmed Barhoum’s Ph.D. work, which was financially supported by the French Culture Center in Cairo (grant no. 759302C), the Medastar Erasmus Mundus Program (Grant no. 2011-4051/002-001-EMA2) and the Strategic Initiative Materials in Flanders (SBO- project no. 130529 - Insitu).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Barhoum, A., Van Lokeren, L., Rahier, H. et al. Roles of in situ surface modification in controlling the growth and crystallization of CaCO3 nanoparticles, and their dispersion in polymeric materials. J Mater Sci 50, 7908–7918 (2015). https://doi.org/10.1007/s10853-015-9327-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-015-9327-z