Abstract

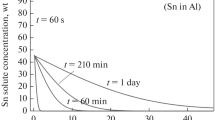

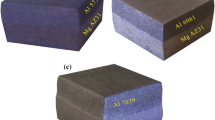

In this study, we conducted the diffusion bonding of Mg and Al alloys using a 30-μm-thick pure silver foil interlayer at median temperatures between 390 and 490 °C. We obtained a multilayered structure across the Mg–Ag–Al joint: Mg/Mg(ss, Ag)/Mg3Ag/MgAg/Ag/Ag(ss, Al)/Ag2Al/Al. The silver diffusion barrier prevented the formation of brittle intermetallics between Mg and Al. Intermetallics identified at the joint interface include the more ductile types between Mg and Ag, ε-Mg3Ag and β′-MgAg, and Ag and Al, δ-Ag2Al. As the bonding temperature increased, Ag2Al, followed by MgAg, favored the growth of Mg3Ag IMC layer. The shear strength of the joints increased with the rising bonding temperature to a maximum value of 11.8 MPa at 470 °C. Fracture failure in the joints mainly occurred in the Ag2Al layer. The formation mechanism for interfacial layers in the joints is believed to consist of four stages: (1) solid-solution formation, (2) Mg–Ag IMC formation, (3) Ag–Al IMC formation, and (4) growth of Mg–Ag and Ag–Al IMCs.

Similar content being viewed by others

References

Song JL, Lin SB, Yang CL, Fan CL (2009) Effects of Si additions on intermetallic compound layer of aluminum–steel TIG welding–brazing joint. J Alloy Compd 488:217–222

Chen YC, Nakata K (2008) Friction stir lap joining aluminum and magnesium alloys. Scr Mater 58:433–436

Zhu B, Liang W, Li XR (2011) Interfacial microstructure, bonding strength and fracture of magnesium–aluminum laminated composite plates fabricated by direct hot pressing. Mater Sci Eng A 528:6584–6588

Liu LM, Wang HY, Zhang ZD (2007) The analysis of laser weld bonding of Al alloy to Mg alloy. Scr Mater 56:473–476

Kwon YJ, Shigematsu I, Saito N (2008) Dissimilar friction stir welding between magnesium and aluminum alloys. Mater Lett 62:3827–3829

Sohn WH, Bong HH, Hong SH (2003) Microstructure and bonding mechanism of Al/Ti bonded joint using Al–10Si–1Mg filler metal. Mater Sci Eng A 355:231–240

Liu P, Li YJ, Geng HR, Wang J (2005) A study of phase constitution near the interface of Mg/Al vacuum diffusion bonding. Mater Lett 59:2001–2005

Choi DH, Ahn BW, Lee ChY, Yeon YM, Song K, Jung SB (2011) Formation of intermetallic compounds in Al and Mg alloy interface during friction stir spot welding. Intermetallics 19:125–130

Dietrich D, Nickel D, Krause M, Lampke T, Coleman MP, Randle V (2011) Formation of intermetallic phases in diffusion-welded joints of aluminium and magnesium alloys. J Mater Sci 46:357–364. doi:10.1007/s10853-010-4841-5

Yang HY, Guo XW, Wu GH, Wang SH, Ding WJ (2011) Continuous intermetallic compounds coatings on AZ91D Mg alloy fabricated by diffusion reaction of Mg–Al couples. Surf Coat Technol 205:2907–2913

Mahendran G, Balasubramanian V, Senthilvelan T (2009) Developing diffusion bonding windows for joining AZ31B magnesium–AA2024 aluminium alloys. Mater Des 30:1240–1244

Joseph Fernandus M, Senthilkumar T, Balasubramanian V, Rajakumar S (2012) Optimising diffusion bonding parameters to maximize the strength of AA6061 aluminium and AZ31B magnesium alloy joints. Mater Des 33:31–41

Zhao LM, Zhang ZD (2008) Effect of Zn alloy interlayer on interface microstructure and strength of diffusion-bonded Mg–Al joints. Scr Mater 58:283–286

Liu LM, Tan JH, Zhao LM, Liu XJ (2008) The relationship between microstructure and properties of Mg/Al brazed joints using Zn filler metal. Mater Charact 59:479–483

Gao M, Mei SW, Li XY, Zeng XY (2012) Characterization and formation mechanism of laser-welded Mg and Al alloys using Ti interlayer. Scr Mater 67:193–196

Zhang J, Luo GQ, Wang YY, Shen Q, Zhang LM (2012) An investigation on diffusion bonding of aluminum and magnesium using a Ni interlayer. Mater Lett 83:189–191

Pouchou JL, Pichoir F (1991) Quantitative analysis of homogeneous or stratified microvolumes applying the model “PAP”. In: Heinrich K, Newbury D (eds) Electron probe quantitation. Plenum Press, New York, pp 31–75

Massalski TB, Okamoto Hiroaki (1990) Binary alloy phase diagrams, 2nd edn. ASM International, Materials Park

Liu CF, Zhang J, Zhou Y, Yi HL, Naka M (2009) Effect of holding time on the self-joining of silicon nitride. J Alloy Compd 471:217–221

Marks RA, Chapman DR, Danielson DT, Glaeser AM (2000) Joining of alumina via copper/niobium/copper interlayers. Acta Mater 48:4425–4438

Wang Y, Luo G, Zhang J, Shen Q, Zhang L (2012) Effect of silver interlayer on microstructure and mechanical properties of diffusion-bonded Mg–Al joints. J Alloy Compd 541:458–461

Bakker H (1990) Diffusion in solid metals and alloys, vol 26. Springer, Berlin

Zhang J, Dou Y, Zheng Y (2014) Twin-boundary segregation energies and solute-diffusion activation enthalpies in Mg-based binary systems: a first-principles study. Scr Mater 80:17–20

Wang J, Hudon P, Kevorkov D, Chartrand P, Jung IH, Medraj M (2014) Thermodynamic and experimental study of the Mg–Sn–Ag–In quaternary system. J Phase Equilib Diff 35(3):284–313. doi:10.1007/s11669-014-0301-2

Lim SS, Rossiter PL, Tibballs JE (1995) Assessment of the Al–Ag binary phase diagram. Calphad 19(2):131–141

Wang C, Zhuang C, Han J, Liu X (2012) Assessment of the atomic mobilities for binary Al–Ag fcc alloys. Calphad 37:145–150

Bridgman PW (1935) Compressibilities and electrical resistance under pressure, with special reference to intermetallic compounds. Proc Am Acad Arts Sci 70:285–317

Shi CX, Li HD, Zhou L (2004) Materials science and engineering handbook. Chemical Industry Press, Beijing

Shiue RH, Wu SK (2006) Infrared brazing of Ti50Ni50 shape memory alloy using two Ag–Cu–Ti active braze alloys. Intermetallics 14:630–638

Huang ZW, Zhao YH, Hou H, Zhao YH, Niu XF, Han PD (2012) Structural, thermodynamics and elastic properties of Mg17Al12, Al2Y and Al4Ba phases by first-principles calculations. J Cent South Univ 19:1475–1481

Steurer W (2007) The Samson phase, β-Mg2Al3, revisited. Z Kristallogr 222(6):259–288

Acknowledgements

The authors gratefully acknowledge financial support from the National Natural Science Foundation of China (No: 51202175), the 111 Project (B13035) of China, the Fundamental Research Funds for the Central Universities (WUT: 2013-II-024), State Key Laboratory of Advanced Technology for Materials Synthesis and Processing (Wuhan University of Technology, Grant No: 2014-KF-7) and China Scholarship Council.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Y., Luo, G., Li, L. et al. Formation of intermetallic compounds in Mg–Ag–Al joints during diffusion bonding. J Mater Sci 49, 7298–7308 (2014). https://doi.org/10.1007/s10853-014-8440-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8440-8