Abstract

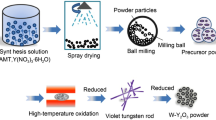

Innovative chemical methods are capable of fabricating nanoscale tungsten oxide compounds doped with various rare-earth elements with high purity and homogeneity, which can be processed under hydrogen into nanostructured oxide-dispersed tungsten composite powders having several potential applications. However, hydrogen reduction of doped tungsten oxide compounds is rather complex, affecting the morphology and composition of the final powder. In this study, we have investigated the reduction of tungstic acid in the presence of Y and we provide the experimental evidence that Y2O3 can be separated from Y-doped tungstic acid via hydrogen reduction to produce Y2O3-W powders. The processed powders were further consolidated by spark plasma sintering at different temperatures and holding times at 75 MPa pressure and characterized. The optimized SPS conditions suggest sintering at 1400 °C for 3 min holding time to achieve higher density composites with an optimum finer grain size (3 µm) and a hardness value up to 420 H V. Major grain growth takes place at temperatures above 1300 °C during sintering. From the density values obtained, it is recommend to apply higher pressure before 900 °C to obtain maximum density. Oxides inclusions present in the matrix were identified as Y2O3·3WO3 and Y2O3·WO3 during high resolution microscopic investigations.

Similar content being viewed by others

References

Lassner E, Schubert W-D (1999) Tungsten: properties, chemistry, technology of the element, alloys, and chemical compounds, 1st edn. Kluwer Academic, New York

Kitsunai Y, Kurishita H, Kayano H, Hiraoka Y, Igarashi T, Takida T (1999) Microstructure and impact properties of ultra-fine grained tungsten alloys dispersed with TiC. J Nucl Mater 271–272:423–428

Faleschini M, Kreuzer H, Kiener D, Pippan R (2007) Fracture toughness investigations of tungsten alloys and SPD tungsten alloys. J Nucl Mater 367–370:800–805

Zhang Y, Ganeev AV, Wang JT, Liu JQ, Alexandrov IV (2009) Observations on the ductile-to-brittle transition in ultrafine-grained tungsten of commercial purity. Mater Sci Eng A 503:37–40

Kurishita H, Matsuso S, Arakawa H, Sakamoto T, Kobayashi S, Nakai K, Takida T, Kato M, Kawai M, Yoshida N (2010) Development of re-crystallized W–1.1%TiC with enhanced room-temperature ductility and radiation performance. J Nucl Mater 398:87–92

Yoo SH, Sudarshan TS, Sethuram K, Subhash G, Dowding RJ (1999) Dynamic compression behavior of tungsten powders consolidated by plasma pressure compaction. Powder Metall 42(2):181–182

Chen W, Kang Z, Ding B (2005) Nanostructured W-La2O3 electrode materials with high content La2O3 doping. Mater Lett 59:1138–1141

Xi X, Nie Z, Wang W, Yang J, Hao S, Guo Y, Zuo T (2005) Study on preparation and emission properties of nano-composite W-La2O3 material. Appl Surf Sci 251:134–138

Oda E, Ameyama K, Yamaguchi S (2006) Fabrication of nano grain tungsten compact by mechanical milling process and its high temperature properties. Mater Sci Forum 503–504:573–578

Kurishita H, Matsuso S, Arakawa H, Hirai T, Linke J, Kawai M, Yoshida N (2009) Development of nanostructured W and Mo materials. Adv Mater Res 59:18–30

Norajitra P, Boccaccini LV, Diegele E et al (2004) Development of a helium-cooled divertor concept: design-related requirements on materials and fabrication technology. J Nucl Mater 329–333:1594–1598

Baluc N (2006) Materials for fusion power reactors. Plasma Phys Controlled Fusion 48:B165–B177

Cottrell GA (2006) A survey of plasma facing materials for fusion power plants. Mater Sci Technol 22:869–880

Norajitra P, Boccaccini LV, Gervash A et al (2007) Development of a helium-cooled divertor: material choice and technological studies. J Nucl Mater 367–370:1416–1421

Wurster S, Pippan R (2009) Nanostructured metals under irradiation. Scr Mater 60:1083–1087

Nita N, Schaeublin R, Victoria M (2004) Impact of irradiation on the microstructure of nanocrystalline materials. J Nucl Mater 329–333:953–957

Chimi Y, Iwase A, Ishikawa N, Kobiyama M, Inami T, Okuda S (2001) Accumulation and recovery of defects in ion-irradiated nanocrystalline gold. J Nucl Mater 297:355–357

Rose M, Balogh AG, Hahn H (1997) Instability of irradiation induced defects in nanostructured materials. Nucl Instrum Methods Phys Res B 127–128:119–122

Shen TD, Feng S, Tang M, Valdez JA, Wang Y, Sickafus KE (2007) Enhanced radiation tolerance in nanocrystalline MgGa2O4. Appl Phys Lett 90(26):263115

Radiguet B, Etienne A, Pareige P, Sauvage X, Valiev R (2008) Irradiation behavior of nanostructured 316 austenitic stainless steel. J Mater Sci 43:7338–7343. doi:10.1007/s10853-008-2875-8

Avettand-Fenoel MN, Taillard R, Dhers J, Foct J (2003) Effect of ball milling parameters on the microstructure of W-Y powders and sintered samples. Int J Refract Met Hard Mater 21:205–213

Malewar R, Kumar KS, Murty BS, Sarma B, Pabi SK (2007) On sinterability of nanostructured W produced by high-energy ball milling. J Mater Res 22(5):1200–1206

Sarkar R, Ghosal P, Premkumar M, Singh AK, Muraleedharan K, Chakraborti A, Bagchi TP, Sarma B (2008) Characterisation and sintering studies of mechanically milled nano tungsten powder. Powder Metall 51(2):166–170

Veleva L, Oksiuta Z, Vogt U, Baluc N (2009) Sintering and characterization of W-Y and W–Y2O3 materials. Fusion Eng Des 84:1920–1924

Zhang Y, Fang Z, Muhammed M, Rao KV, Skumryev V, Medelius H, Costa JL (1989) The synthesis of superconducting bismuth compounds via oxalate coprecipitation. Phys C 157:108–114

Wang L, Zhang Y, Muhammed M (1995) Synthesis of nanophase oxalate precursors of YBaCuO superconductor by coprecipitation in microemulsions. J Mater Chem 5(2):309–314

Xi X, Nie Z, Yang J, Fu X, Wang W, Zuo T (2005) Preparation and characterization of Ce–W composite nanopowder. Mater Sci Eng A 394:360–365

Ryu T, Hwang KS, Choi YJ, Sohn HY (2009) The sintering behavior of nanosized tungsten powder prepared by a plasma process. Int J Refract Met Hard Mater 27:701–704

Wahlberg S, Grenthe I, Muhammed M (1997) Nanostructured hard material composites by molecular engineering 1. Synthesis from soluble tungstate salts. Nanostruct Mater 9:105–108

Muhammed M, Wahlberg S, Grenthe I (1995) Method of preparing powders for hard materials. Swedish Pat. SE9402081

Zhang Z, Wahlberg S, Wang M, Muhammed M (1999) Processing of nanostructured WC-Co powders from precursor obtained by co-precipitation. Nanostruct Mater 12:163–166

Zhang Z, Zhang Y, Muhammed M (2002) The reduction of cobalt doped ammonium paratungstate to nanostructured W-Co powder. Int J Refract Met Hard Mater 20:227–233

Zhang Z, Muhammed M (2003) Thermochemical decomposition of cobalt doped ammonium paratungstate precursor. Thermochim Acta 400:235–245

Yar MA, Wahlberg S, Bergqvist H, Salem HG, Johnsson M, Muhammed M (2011) Chemically produced nanostructured ODS–lanthanum oxide–tungsten composites sintered by spark plasma. J Nucl Mater 408:129–135

Yar MA, Wahlberg S, Bergqvist H, Salem HG, Johnsson M, Muhammed M (2011) Spark plasma sintering of tungsten–yttrium oxide composites from chemically synthesized nanopowders and microstructural characterization. J Nucl Mater 412:227–232

Wahlberg S, Yar MA, Abuelnaga MO, Salem HG, Johnsson M, Muhammed M (2012) Fabrication of nanostructured W-Y2O3 materials by chemical methods. J Mater Chem 22:12622–12628

Borchardt HJ (1963) Yttrium-tungsten oxides. Inorg Chem 2(1):170–173

Tan J, Zhou Z, Zhong M, Zhu X, Lei M, Liu W, Ge C (2011) Annealing behaviour and transient high-heat loading performance of different grade finegrained tungsten. Phys Scr 145:014055

Fang ZZ, Wang H (2008) Densification and grain growth during sintering of nanosized particles. Int Mater Rev 53(6):326–352

Viswanathan V, Laha T, Balani K, Agarwal A, Seal S (2006) Challenges and advances in nanocomposite processing techniques. Mater Sci Eng R 54:121–285

Zhou Z, Pintsuk G, Jochen Linke, Hirai T, Rödig M, Ma Y, Ge C (2010) Transient high heat load tests on pure ultra-fine grained tungsten fabricated by resistance sintering under ultra-high pressure. Fusion Eng Des 85:115–121

Ma Y, Zhou Z, Tan J, Li M (2011) Fabrication of ultra-fine grain tungsten by combining spark plasma sintering with resistance sintering under ultra high pressure. Rare Met Mater Eng 40(1):0004–0008

Xie ZM, Liu R, Fang QF, Zhou Y, Wang XP, Liu CS (2014) Spark plasma sintering and mechanical properties of zirconium micro-alloyed tungsten. J Nucl Mater 444:175–180

Mcwilliams B, Zavaliangos A, Cho KC, Dowding RJ (2006) The modelling of electric-current-assisted sintering to produce bulk nanocrystalline tungsten. J Miner Met Mater Soc 58(4):67–71

Maizza G, Grasso S, Sakka Y, Noda T, Ohashi O (2007) Relation between microstructure, properties and spark plasma sintering (SPS) parameters of pure ultrafine WC powder. Sci Technol Adv Mater 8:644–654

Haubner R, Schubert WD, Hellmer H, Lassner E, Lux B (1983) Mechanism of technical reduction of tungsten: part 1. Literature review. J Refract Met Hard Mater 2:108–115

Haubner R, Schubert WD, Hellmer H, Lassner E, Lux B (1983) Mechanism of technical reduction of tungsten: part 2. Hydrogen reduction of tungsten blue oxide to tungsten powder. J Refract Met Hard Mater 2:156–163

Schubert WD (1990) Kinetics of hydrogen reduction of tungsten oxides. J Refract Met Hard Mater 4:178–191

Millner T (1974) Story of beryllium containing additives in large crystalline metallic tungsten. Acta Chim 82(1):1–9

Huang J, Xu J, Li H, Luo H, Yu X, Li Y (2011) Determining the structure of tetragonal Y2WO6 and the site occupation of Eu3+ dopant. J Solid State Chem 184:843–847

Wang J, Zhang ZJ, Zhao JT, Chen HH, Yang XX, Tao Y, Huang Y (2010) Luminescent metastable Y2WO6:Ln3+ (Ln = Eu, Er, Sm, and Dy) microspheres with controllable morphology via self-assembly. J Mater Chem 20:10894–10900

Acknowledgements

Authors of the work are thankful to Prof. John Ågren and Dr. Peter Hedström at Department of Materials Science and Engineering-KTH, Oskar Karlsson at Swerea-Kimab AB, for EBSD and hardness measurements. Dr. M. Waldenström at Sandvik AB is acknowledged for providing APT. M. A. Yar is grateful to Higher Education Commission (HEC), Government of Pakistan for financial support during his PhD studies.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yar, M.A., Wahlberg, S., Abuelnaga, M.O. et al. Processing and sintering of yttrium-doped tungsten oxide nanopowders to tungsten-based composites. J Mater Sci 49, 5703–5713 (2014). https://doi.org/10.1007/s10853-014-8289-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8289-x