Abstract

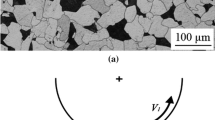

The study examined the microstructural and textural evolution of low carbon steel samples fabricated using a differential speed rolling (DSR) process with respect to the number of operations. For this purpose, the samples were deformed by up to 4-pass of DSR at room temperature with a roll speed ratio of 1:4 for the lower and upper rolls, respectively. The DSR technique applied to low carbon steel samples resulted in a microstructure composed of ultrafine ferrite grains, approximately 0.4 µm in size, after 4-pass with a high-angle grain boundary fraction of ~65 %. The microstructural features of the ferrite phase indicated the occurrence of continuous dynamic recrystallization, beginning with the formation of a necklace-like structure of ultrafine equiaxed grains around the elongated grains, which were formed in the early stages of deformation, and ending with ultrafine recrystallized grains surrounded by boundaries with high angles of misorientations. In the pearlite phase, the microstructural changes associated with DSR deformation were presented by the occurrence of bending, kinking, and breaking of the cementite lamellar plates. In addition, the evolution of texture after DSR processing was affected by shear deformation and rolling deformation, leading to the formation of a texture composed of fractions of components with shear texture orientations such as {110} 〈001〉 (Goss) and orientations close to {112} 〈111〉, in addition to rolling texture components consisting mainly of α-fiber and γ-fiber.

Similar content being viewed by others

References

Valiev RZ, Islamgaliev RK, Alexandrov IV (2006) Bulk nanostructured materials from severe plastic deformation. Prog Mater Sci 51:881–981

Valiev RZ, Langdon TG (2006) Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog Mater Sci 45:881–981

Yuanyuan L, Datong Z, Weiping C, Ying L, Guowen G (2004) Microstructure evolution of AZ31 magnesium alloy during equal channel angular extrusion. J Mater Sci 39:3759–3761. doi:10.1023/B:JMSC.0000030731.04301.5f

Zhilyaev AP, Langdon TG (2008) Using high-pressure torsion for metal processing: fundamentals and applications. Prog Mater Sci 53:893–979

Yoon EY, Lee DJ, Bark B, Akbarpour MR, Farvizi M, Kim HS (2013) Grain refinement and tensile strength of carbon nanotube-reinforced Cu matrix nanocomposites processed by high-pressure torsion. Met Mater Int 19:927–932

Tsuji N, Saito Y, Lee SH, Minamino Y (2003) ARB (accumulative roll-bonding) and other new techniques to produce bulk ultrafine grained materials. Adv Eng Mater 5:338–344

Lee SH, Kim JH (2013) Mechanical properties of a complex AA1050/AA5052 aluminum alloy fabricated by an ARB. Korean J Met Mater 51:251–257

Orlov D, Lapovok R, Toth LS, Timokhina IB, Hodgson PD, Haldar A, Bhattacharjee D (2014) Asymmetric rolling of interstitial-free steel using differential roll diameters, Part II: microstructure and annealing effects. Metall Mater Trans A 45:447–454

Orlov D, Pougis A, Lapovok R, Toth LS, Timokhina IB, Hodgson PD, Haldar A, Bhattacharjee D (2013) Asymmetric rolling of interstitial-free steel using differential roll diameters. Part I: mechanical properties and deformation textures. Metall Mater Trans A 44:4346–4359

Sidor J, Petrov RH, Kestens LAI (2010) Deformation, recrystallization and plastic anisotropy of asymmetrically rolled aluminum sheets. Mater Sci Eng A 528:413–424

Lapovok R, Toth LS, Winkler M, Semiatin SL (2009) A comparison of continuous SPD processes for improving the mechanical properties of aluminum alloy 6111. J Mater Res 24:459–469

Hamad K, Chung KB, Ko YG (2014) Microstructure and mechanical properties of severely deformed Mg–3 %Al–1 %Zn alloy via isothermal differential speed rolling at 453 K. J Alloys Compd. doi:10.1016/j.jallcom.2013.12.195

Kim WJ, Lee JB, Kim WY, Jeong HT, Jeong HG (2007) Microstructure and mechanical properties of Mg–Al–Zn alloy sheets severely deformed by asymmetrical rolling. Scripta Mater 56:309–312

Kim HS, Yoo SJ, Ahn JW, Kim DH, Kim WJ (2011) Ultrafine grained titanium sheets with high strength and high corrosion resistance. Mater Sci Eng A 528:8479–8485

Huang X, Suzuki K, Chino Y (2010) Improvement of stretch formability of pure titanium sheet by differential speed rolling. Scripta Mater 63:473–476

Loorentz YGK (2012) Microstructure evolution and mechanical properties of severely deformed Al alloy processed by differential speed rolling. J Alloys Compd 536:S122–S125

Loorentz YGK (2014) Effect of differential speed rolling strain on microstructure and mechanical properties of nanostructured 5052 Al alloy. J Alloys Compd 586:S205–S209

Polkowski W, Jozwik P, Polanski M, Bojar Z (2013) Microstructure and texture evolution of copper processed by differential speed rolling with various speed asymmetry coefficient. Mater Sci Eng A 564:289–297

Kim WJ, Lee KE, Choi SH (2009) Mechanical properties and microstructure of ultrafine grained copper prepared by a high-speed-ratio differential speed rolling. Mater Sci Eng A 506:71–79

Ko YG, Suharto J, Park BH, Shin DH (2013) Effect of speed ratio on deformation characterization of IF steel subjected to differential speed rolling. Met Mater Int 19:603–609

Suharto J, Ko YG (2012) Annealing behavior of severely deformed IF steel via the differential speed rolling method. Mater Sci Eng A 558:90–94

Kim WJ, Wang JY, Choi SO, Choi JJ, Sohn HT (2009) Synthesis of ultra-high strength Al–Mg–Si alloy sheets by differential speed rolling. Mater Sci Eng A 520:23–28

Zubaydi A, Figueiredo RB, Huang Y, Langdon TG (2013) Structural and hardness inhomogeneities in Mg–Al–Zn alloys processed by high-pressure torsion. J Mater Sci 48:4661–4670. doi:10.1007/s10853-013-7176-1

Xu J, Wang X, Zhu X, Shirooyeh M, Ngam JW, Shan D, Guo B, Langdon TG (2013) Dry sliding wear of an AZ31 magnesium alloy processed by equal-channel angular pressing. J Mater Sci 48:4117–4127. doi:10.1007/s10853-013-7224-x

Shin DH, Park KT (2005) Ultrafine grained steels processed by equal channel angular pressing. Mater Sci Eng A 410:299–302

Son YI, Lee YK, Park KT, Lee CS, Shin DH (2005) Ultrafine grained ferrite–martensite dual phase steels fabricated via equal channel angular pressing: microstructure and tensile properties. Acta Mater 53:3125–3134

Shin DH, Kim I, Kim J, Park KT (2001) Grain refinement mechanism during equal-channel angular pressing of a low-carbon steel. Acta Mater 49:1285–1292

Fukuda Y, Oh-ishi K, Horita Z, Langdon TG (2002) Processing of a low-carbon steel by equal-channel angular pressing. Acta Mater 50:1359–1368

Maier GG, Astafurova EG, Maier HJ, Naydenkin EV, Raab GI, Odessky PD, Dobatkin SV (2013) Annealing behavior of ultrafine grained structure in low-carbon steel produced by equal channel angular pressing. Mater Sci Eng A 581:104–107

Sitdikov O, Sakai T, Avtokratova E, Kaibyshev R, Tsuzaki K, Watanabe Y (2008) Microstructure behavior of Al–Mg–Sc alloy processed by ECAP at elevated temperature. Acta Mater 56:821–834

Mazurina I, Sakai T, Miura H, Sitdikov O, Kaibyshev R (2008) Grain refinement in aluminum alloy 2219 during ECAP at 250°C. Mater Sci Eng A 473:1297–1305

Cui Q, Ohori K (2000) Grain refinement of high purity aluminum by asymmetric rolling. Mater Sci Technol 16:1095–1101

Sakai T, Belyakov A, Kaibyshev R, Miura H, Jonas JJ (2014) Dynamic and post-dynamic recrystallization under hot, cold and severe plastic deformation conditions. Prog Mater Sci 60:130–207

Shin DH, Kim BC, Kim YS, Park KT (2000) Microstructure evolution in commercial low carbon steel by equal channel angular pressing. Acta Mater 48:2247–2255

Xiong Y, He T, Guo Z, He H, Ren F, Volinsky A (2013) Mechanical properties and fracture characteristics of high carbon steel after equal channel angular pressing. Mater Sci Eng A 563:163–167

Kamikawa N, Sakai T, Tsuji N (2007) Effect of redundant shear strain on microstructure and texture evolution during accumulative roll-bonding in ultralow carbon IF steel. Acta Mater 55:5873–5888

Acknowledgements

This work was supported by funding from the Yeungnam University Research Project (213-A-380010).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hamad, K., Megantoro, R.B. & Ko, Y.G. Microstructure and texture evolution in low carbon steel deformed by differential speed rolling (DSR) method. J Mater Sci 49, 6608–6619 (2014). https://doi.org/10.1007/s10853-014-8280-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8280-6