Abstract

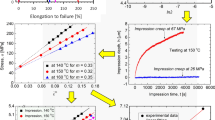

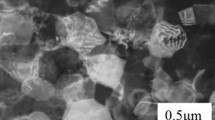

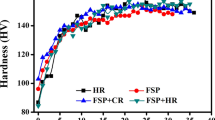

Ultrafine-grained (UFG) Al–Mg–Sc alloy was obtained by friction stir processing. The UFG alloy was subjected to uniaxial tensile testing to study the tensile deformation behavior of the alloy. An inhomogeneous yielding (Lüdering phenomenon) was observed in the stress–strain curves of UFG alloy. This deformation behavior was absent in the coarse-grained alloy. The Lüdering phenomenon in UFG alloy was attributed to the lack of dislocations in UFG microstructure. A strong dependence of uniform ductility on the average grain size was exhibited by the UFG alloy. Below a critical grain size (0.5 μm), ductility was very limited. Also, with the decrease in grain size, most of the plastic deformation was observed to be localized in necked region of the tensile samples. The negative strain rate sensitivity (SRS) observed for the UFG alloy was opposite of the SRS values reported for UFG alloys in the literature. Based on activation volume measurement, grain boundary mediated dislocation-based plasticity was concluded to be the micro-mechanism operative during plastic deformation of UFG Al–Mg–Sc alloy.

Similar content being viewed by others

References

Valiev RZ, Krasilnikov NA, Tsenev NK (1991) Plastic deformation of alloys with submicron-grained structure. Mater Sci Eng, A 137:35–40

Gleiter H (1992) Materials with ultrafine microstructures: retrospectives and perspectives. Nanostruct Mater 1:1–19

Valiev RZ, Kozlov EV, Ivanov YF, Lian J, Nazarov AA, Baudelet B (1994) Deformation behaviour of ultra-fine-grained copper. Acta Metall Mater 42:2467–2474

Yu CY, Kao PW, Chang CP (2005) Transition of tensile deformation behaviors in ultrafine-grained aluminum. Acta Mater 53:4019–4028

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Bulk nanostructured materials from severe plastic deformation. Prog Mater Sci 45:103–189

Hall EO (1951) The deformation and ageing of mild steel: III discussion of results. Proc Phys Soc B 64:747–753

Petch NJ (1953) The cleavage strength of polycrystals. Iron Steel Inst 174:25–28

Kaufman JG (1999) Properties of aluminum alloys: tensile, creep, and fatigue data at high and low temperatures. ASM International, Materials Park

Tellkamp VL, Melmed A, Lavernia EJ (2001) Mechanical behavior and microstructure of a thermally stable bulk nanostructured Al alloy. Metall Mater Trans A 32:2335–2343

Hayes RW, Witkin D, Zhou F, Lavernia EJ (2004) Deformation and activation volumes of cryomilled ultrafine-grained aluminum. Acta Mater 52:4259–4271

Higashi K, Patlan V, Kitagawa K, Kawazoe M (2001) Tensile and low-cycle fatigue properties of heat treated ultra-fine grain 5056 aluminum alloy. J Japan Inst Light Met 51:646–650

Stolyarov VV, Lapovok R (2004) Effect of backpressure on structure and properties of AA5083 alloy processed by ECAP. J Alloys Compd 378:233–236

Chang SY, Lee JG, Park KT, Shin DH (2001) Microstructures and mechanical properties of equal channel angular pressed 5083 Al alloy. Mater Trans 42:1074–1080

Valiev RZ, Langdon TG (2006) Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog Mater Sci 51:881–981

Zhilyaev AP, Langdon TG (2008) Using high-pressure torsion for metal processing: fundamentals and applications. Prog Mater Sci 53:893–979

Saito Y, Utsunomiya H, Tsuji N, Sakai T (1999) Novel ultra-high straining process for bulk materials—development of the accumulative roll-bonding (ARB) process. Acta Mater 47:579–583

Tsuji N, Saito Y, Lee S-H, Minamino Y (2003) ARB (Accumulative Roll-Bonding) and other new techniques to produce bulk ultrafine grained materials. Adv Eng Mater 5:338–344

Mishra RS, Ma ZY (2005) Friction stir welding and processing. Mater Sci Eng, R 50:1–78

Witkin DB, Lavernia EJ (2006) Synthesis and mechanical behavior of nanostructured materials via cryomilling. Prog Mater Sci 51:1–60

Kwon YJ, Saito N, Shigematsu I (2002) Friction stir process as a new manufacturing technique of ultrafine grained aluminum alloy. J Mater Sci Lett 21:1473–1476

Su J-Q, Nelson TW, Sterling CJ (2003) A new route to bulk nanocrystalline materials. J Mater Res 18:1757–1760

Charit I, Mishra RS (2005) Low temperature superplasticity in a friction-stir-processed ultrafine grained Al–Zn–Mg–Sc alloy. Acta Mater 53:4211–4223

Ma ZY, Mishra RS (2005) Development of ultrafine-grained microstructure and low temperature (0.48 T m) superplasticity in friction stir processed Al–Mg–Zr. Scripta Mater 53:75–80

Argade GR, Yuan W, Kandasamy K, Mishra RS (2012) Stress corrosion cracking susceptibility of ultrafine grained AZ31. J Mater Sci 47:6812. doi:10.1007/s10853-012-6625-6

Su JQ, Nelson TW, Sterling CJ (2006) Grain refinement of aluminum alloys by friction stir processing. Philos Mag 86:1–24

Ma ZY, Liu FC, Mishra RS (2010) Superplastic deformation mechanism of an ultrafine-grained aluminum alloy produced by friction stir processing. Acta Mater 58:4693–4704

Kumar N, Mishra RS, Huskamp CS, Sankaran KK (2011) Critical grain size for change in deformation behavior in ultrafine grained Al–Mg–Sc alloy. Scripta Mater 64:576–579

Kumar N, Mishra RS, Huskamp CS, Sankaran KK (2011) Microstructure and mechanical behavior of friction stir processed ultrafine grained Al–Mg–Sc alloy. Mater Sci Eng, A 528:5883–5887

Kumar N, Mishra RS (2013) Ultrafine-grained Al–Mg–Sc alloy via friction-stir processing. Metall Mat Trans A 44:934–945

May J, Höppel HW, Göken M (2005) Strain rate sensitivity of ultrafine-grained aluminium processed by severe plastic deformation. Scripta Mater 53:189–194

Wei Q, Cheng S, Ramesh KT, Ma E (2004) Effect of nanocrystalline and ultrafine grain sizes on the strain rate sensitivity and activation volume: fcc versus bcc metals. Mater Sci Eng, A 381:71–79

Ding Y, Jiang J, Shan A (2009) Plastic instability and strain rate sensitivity of ultrafine-grained iron. J Alloys Compd 487:517–521

Conrad H, Jung K (2005) On the strain rate sensitivity of the flow stress of ultrafine-grained Cu processed by equal channel angular extrusion (ECAE). Scripta Mater 53:581–584

Carreker RP Jr, Hibbard WR Jr (1953) Tensile deformation of high-purity copper as a function of temperature, strain rate, and grain size. Acta Metall 1:654–663

Valiev RZ, Enikeev NA, Murashkin MY, Kazykhanov VU, Sauvage X (2010) On the origin of the extremely high strength of ultrafine-grained Al alloys produced by severe plastic deformation. Scripta Mater 63:949–952

Yapici GG, Beyerlein IJ, Karaman I, Tomé CN (2007) Tension–compression asymmetry in severely deformed pure copper. Acta Mater 55:4603–4613

Tsuji N, Ito Y, Saito Y, Minamino Y (2002) Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing. Scripta Mater 47:893–899

Koch CC (2003) Ductility in nanostructured and ultra fine-grained materials: recent evidence for optimism. J Meta Nanocryst Mater 18:9–20

Mukai T, Kawazoe M, Higashi K (1998) Dynamic mechanical properties of a near-nano aluminum alloy processed by equal-channel-angular-extrusion. Nanostruct Mater 10:755–765

Kapoor R, De PS, Mishra RS (2010) An analysis of strength and ductility of ultrafine grained Al alloys, Mate. Sci Forum 633–634:165–167

Filatov YA, Yelagin VI, Zakharov VV (2000) New Al–Mg–Sc alloys. Mater Sci Eng, A 280:97–101

Ahmad Z (2003) The properties and application of scandium-reinforced aluminum. JOM 55(3):35–39

Davydov VG, Elagin VI, Zakharov VV, Rostova TD (1996) Alloying aluminum alloys with scandium and zirconium additives. Met Sci Heat Treat 38:347–352

Yin Z, Pan Q, Zhang Y, Jiang F (2000) Effect of minor Sc and Zr on the microstructure and mechanical properties of Al–Mg based alloys. Mater Sci Eng A 280:151–155

Kaibyshev R, Sitdikov O, Olenyov S (2002) Ultrafine grain formation during equal channel angular extrusion in an Al–Mg–Sc Alloy. In: Zhu YT, Langdon TG, Mishra RS, Semiatin SL, Saran MJ, Lowe TC (eds) Ultrafine grained materials II. TMS Annual Meeting, Seattle, pp 65–74

Valiev RZ, Vishnyakov YD, Mulyukov RR, Fainshtein GS (1990) On the decrease of curie temperature in submicron-grained nickel. Phys Status Solidi A 117:549–553

Sabirov I, Estrin Y, Barnett MR, Timokhina I, Hodgson PD (2008) Enhanced tensile ductility of an ultra-fine-grained aluminum alloy. Scripta Mater 58:163–166

Hart EW (1967) Theory of the tensile test. Acta Metall 15:351–355

Dieter GE (1988) Mechanical metallurgy. McGraw-Hill, Singapore

Kocks UF, Mecking H (2003) Physics and phenomenology of strain hardening: the FCC case. Prog Mater Sci 48:171–273

Wang Y, Chen M, Zhou F, Ma E (2002) High tensile ductility in a nanostructured metal. Nature 419:912–915

Ma E (2003) Instabilities and ductility of nanocrystalline and ultrafine-grained metals. Scripta Mater 49:663–668

Torre D, Pereloma EV, Davies CHJ (2004) Strain rate sensitivity and apparent activation volume measurements on equal channel angular extruded Cu processed by one to twelve passes. Scripta Mater 51:367–371

Wei Y, Gao H (2008) An elastic–viscoplastic model of deformation in nanocrystalline metals based on coupled mechanisms in grain boundaries and grain interiors. Mater Sci Eng, A 478:16–25

Kubin LP, Chihab K, Estrin Y (1988) The rate dependence of the portevin-Le chatelier effect. Acta Metall 36:2707–2718

Han BQ, Huang J, Zhu YT, Lavernia EJ (2006) Negative strain-rate sensitivity in a nanostructured aluminum alloy. Adv Eng Mater 8:945–947

Ahn B, Mitra R, Lavernia EJ, Nutt SR (2010) Effect of grain size on strain rate sensitivity of cryomilled Al–Mg alloy. J Mater Sci 45:4790. doi:10.1007/s10853-010-4664-4

Fan GJ, Wang GY, Choo H, Liaw PK, Park YS, Han BQ, Lavernia EJ (2005) Deformation behavior of an ultrafine-grained Al–Mg alloy at different strain rates. Scripta Mater 52:929–933

Sha G, Yao L, Liao X, Ringer SP, Duan ZC, Langdon TG (2011) Segregation of solute elements at grain boundaries in an ultrafine grained Al–Zn–Mg–Cu alloy. Ultramicroscopy 111:500–505

Meyers MA, Mishra A, Benson DJ (2006) Mechanical properties of nanocrystalline materials. Prog Mater Sci 51:427–556

Blum W, Zeng XH (2009) A simple dislocation model of deformation resistance of ultrafine-grained materials explaining Hall–Petch strengthening and enhanced strain rate sensitivity. Acta Mater 57:1966–1974

Kapoor R, Gupta C, Sharma G, Chakravartty JK (2005) Deformation behavior of Al–1.5 Mg processed using the equal channel angular pressing technique. Scripta Mater 53:1389–1393

Muñoz-Morris MA, Garcia OC, Morris DG (2003) Mechanical behaviour of dilute Al–Mg alloy processed by equal channel angular pressing. Scripta Mater 48:213–218

Conrad H, Narayan J (2002) Mechanisms for grain size hardening and softening in Zn. Acta Mater 50:5067–5078

Wang YM, Ma E (2004) Three strategies to achieve uniform tensile deformation in a nanostructured metal. Acta Mater 52:1699–1709

Li YJ, Zeng XH, Blum W (2004) Transition from strengthening to softening by grain boundaries in ultrafine-grained Cu. Acta Mater 52:5009–5018

Conrad H, Yang D (2002) Plastic deformation kinetics of electrodeposited Cu foil at low and intermediate homologous temperatures. J Electron Mater 31:304–312

Deep G, Plumtree A (1975) Yield point behavior in extruded aluminum rod. Metall Trans A6:359–366

Lloyd DJ, Morris LR (1977) Luders band deformation in a fine grained aluminium alloy. Acta Metall 25:857–861

Wyrzykowski JW, Grabski MW (1982) Lüders deformation in ultrafine-grained pure aluminium. Mater Sci Eng 56:197–200

Hung PC, Sun PL, Yu CY, Kao PW, Chang CP (2005) Inhomogeneous tensile deformation in ultrafine-grained aluminum. Scripta Mater 53:647–652

Acknowledgements

Authors would like to thank The Boeing Company, St. Louis for supplying the material and financial assistance.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kumar, N., Komarasamy, M. & Mishra, R.S. Plastic deformation behavior of ultrafine-grained Al–Mg–Sc alloy. J Mater Sci 49, 4202–4214 (2014). https://doi.org/10.1007/s10853-014-8115-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8115-5