Abstract

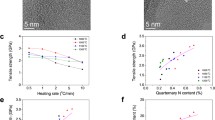

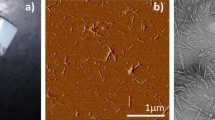

Carbon papers (CPs) have been fabricated using wet-laying carbon fibers (CFs) and polyacrylonitrile (PAN) fibers. Scanning electron microscopy revealed that the PAN fibers tightly interconnected the CF junctions with the pores between the fibers. The tensile strength of the carbon webs (CWs) increased as the fraction of PAN fibers used as the binder increased. The CW fabricated with 0.15 wt% PAN fibers had a tensile strength six times greater than that of the CW without PAN fibers. Moreover, by mixing the CFs with PAN fibers in water, the CFs separated from each other in the webs due to the interruption of hydrophobicity between the CFs. After mixing with PAN fibers, the CWs were carbonized at 1200 °C in the presence of a phenolic resin. The PAN fibers maintained their morphology due to their high carbon content after carbonization. The electrical resistivity of the CPs with high PAN fiber content was significantly lower than that of a CP without PAN fibers due to the interconnection of the CFs by the carbonized PAN fibers.

Similar content being viewed by others

References

Cindrella L, Kannan AM, Lin JF, Saminathan K, Ho Y, Lin CW, Wertz J (2009) Gas diffusion layer for proton exchange membrane fuel cells—a review. J Power Sources 194:146–160

Martínez-Rodríguez MJ, Cui T, Shimpalee S, Seraphin S, Duong B, Van Zee JW (2012) Effect of microporous layer on MacMullin number of carbon paper gas diffusion layer. J Power Sources 207:91–100

Ihonen J, Mikkola M, Lindbergh G (2004) Flooding of gas diffusion backing in PEFCs physical and electrochemical characterization. J Electrochem Soc 151:A1152–A1161

Vielstich W, Lamm A, Gasteiger HA (2003) Handbook of fuel cells: fundamentals, technology, applications, 1st edn. Wiley, New York

Park GG, Sohn YJ, Yang TH, Yoon YG, Lee WY, Kim CS (2004) Effect of PTFE contents in the gas diffusion media on the performance of PEMFC. J Power Sources 131:182–187

Williams MV, Begg E, Bonville L, Kunz HR, Fenton JM (2004) Characterization of gas diffusion layers for PEMFC. J Electrochem Soc 151:A1173–A1180

Jabbour L, Gerbaldi C, Chaussy D, Zeno E, Bodoardo S, Beneventi D (2010) Microfibrillated cellulose–graphite nanocomposites for highly flexible paper-like Li-ion battery electrodes. J Mater Chem 20:7344–7347

Jabbour L, Chaussy D, Eyraud B, Beneventi D (2012) Highly conductive graphite/carbon fiber/cellulose composite papers. Compos Sci Technol 72:616–623

Yan X, Tai Z, Chena J, Xue Q (2011) Fabrication of carbon nanofiber–polyaniline composite flexible paper for supercapacitor. Nanoscale 3:212–216

Rahaman MSA, Ismail AF, Mustafa A (2007) A review of heat treatment on polyacrylonitrile fiber. Polym Degrad Stab 92:1421–1432

Cato AD, Edie DD (2003) Flow behavior of mesophase pitch. Carbon 41:1411–1417

Kim S, Chung YS, Choi HS, Jin FL, Park SJ (2013) Preparation and characterization of PAN-based superfined carbon fibers for carbon-paper applications. Bull Korean Chem Soc 34:3733–3737

Mathur RB, Maheshwari PH, Dhami TL, Tandon RP (2007) Characteristics of the carbon paper heat-treated to different temperatures and its influence on the performance of PEM fuel cell. Electrochim Acta 52:4809–4817

Kim H, Lee YJ, Lee DC, Park GG, Yoo Y (2013) Fabrication of the carbon paper by wet-laying of ozone-treated carbon fibers with hydrophilic functional groups. Carbon 60:429–436

Park SJ, Chang YH, ChangYH Moon CW, Suh DH, Im SS, Kim YC (2010) A study of atmospheric plasma treatment on surface energetics of carbon fibers. Bull Korean Chem Soc 31:335–338

Osbeck S, Bradley RH, Liu C, Idriss H, Ward S (2011) Effect of an ultraviolet/ozone treatment on the surface texture and functional groups on polyacrylonitrile carbon fibres. Carbon 49:4322–4330

Mathur RB, Bahl OP, Sivaram P (1992) Thermal degradation of polyacrylonitrile fibres. Curr Sci 62:662–669

Yue ZR, Jiang W, Wang L, Gardner SD, Pittman CU Jr (1999) Surface characterization of electrochemically oxidized carbon fibers. Carbon 37:1785–1796

Morita K, Murata Y, Ishitani A, Murayama K, Ono T, Nakajima A (1986) Characterization of commercially available PAN(polyacrylonitrile)-based carbon fibers. Pure Appl Chem 58:455–468

Jones C (1991) The chemistry of carbon fibre surfaces and its effect on interfacial phenomena in fibre/epoxy composites. Compos Sci Technol 42:275–298

Gardner SD, Singamsetty CSK, Booth GL, He GR, Pittman CU Jr (1995) Surface characterization of carbon fibers using angle-resolved XPS and ISS. Carbon 33:587–595

Jones C, Sammann E (1990) The effect of low power plasmas on carbon fibre surfaces. Carbon 28:509–514

Gostick JT, Fowler MW, Ioannidis MA, Pritzker MD, Volfkovich YM, Sakars A (2006) Capillary pressure and hydrophilic porosity in gas diffusion layers for polymer electrolyte fuel cells. J Power Sources 156:375–387

Fishman Z, Hinebaugh J, Bazylak A (2010) Microscale tomography investigation of heterogenous porosity distribution of PEMFC GDLs. J Electrochem Soc 157:B1643–B1650

Gostick JT, Fowler MW, Pritzker MD, Ioannidis MA, Behra LM (2006) In-plane and through-plane gas permeability of carbon fiber electrode backing layers. J Power Sources 162:228–238

Yim SD, Kim BJ, Sohn YJ, Yoon YG, Park GG, Lee WY, Kim CS, Kim YC (2010) The influence of stack clamping pressure on the performance of PEM fuel cell stack. Curr Appl Phys 10:S59–S61

Hwang GS, Weber AZ (2012) Effective-diffusivity measurement of partially-saturated fuel-cell gas-diffusion layers fuel cells, electrolyzers, and energy conversion. J Electrochem Soc 159:F683–F692

Acknowledgements

We gratefully acknowledge the Principal Project of the Korea Institute of Energy Research (KIER) funded by the Ministry of Science, ICT & Future Planning of the Republic of Korea (B3-2413-04).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Kim, H., Lee, YJ., Lee, SJ. et al. Fabrication of carbon papers using polyacrylonitrile fibers as a binder. J Mater Sci 49, 3831–3838 (2014). https://doi.org/10.1007/s10853-014-8096-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-014-8096-4