Abstract

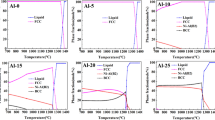

The effects of varying the Al content in the range of 11–15 at.% on the microstructure and room-temperature mechanical properties of lamellar-structured FeNiMnAl alloys with compositions close to Fe30Ni20Mn35Al15 have been studied, and the temperature dependence of the yield strength of one composition, i.e., Fe36Ni18Mn33Al13, has been investigated. All alloys consisted of B2 and fcc phases. Decreasing the Al content initially (13 and 14 at.% Al) led to marked increases in both the fcc phase fraction and fcc lamellar spacing, λ, but, on further reducing the Al content (11 and 12 at.% Al), the lamellar structure was no longer present. The elongation to fracture of the FeNiMnAl alloys increased with the decreasing Al concentration from 6.5 % at 15 at.% Al to 31.1 % at 11 at.% Al with a concomitant decrease in the yield stress from 820 to 255 MPa. For the lamellar-structured alloys, the yield stress, σ y, obeyed a Hall–Petch-type relationship with λ, i.e., \( \sigma_{y } = \sigma^{\prime}_{0} + k^{\prime}\lambda^{ - 1} \), where \( \sigma^{\prime}_{0} \) is the lattice resistance, and k′ is a constant. The compressive yield stress of Fe36Ni18Mn33Al13 was found to be independent of temperature up to 700 K, after which it decreased dramatically because of the softening of the B2 phase. All alloys showed ductile fracture modes.

Similar content being viewed by others

References

Deevi SC, Sikka VK (1996) Nickel and iron aluminides: an overview on properties, processing, and applications. Intermetallics 4(5):357–375

Dimiduk DM, Miracle DB, Ward CH (1992) Development of intermetallic materials for aerospace systems. Mater Sci Technol (Lond) 8(4):367–375

Fleischer RL (1987) High-strength, high-temperature intermetallic compounds. J Mater Sci 22(7):2281–2288. doi:10.1007/BF01082105

Anton DL, Shah DM, Duhl DN, Giamei AF (1989) Selecting high-temperature structural intermetallic compounds: the engineering approach. JOM 41(9):12–17

Kumar KS, Liu CT (1993) Ordered intermetallic alloys, part II: silicides, trialuminides, and others. JOM 45(6):28–34

Cahn RW, West DRF, Dunstan DJ, McLean M, Martin JW, Morris D (1995) Multiphase intermetallics [and discussion]. Philos Trans R Soc Lond A 351(1697):497–509

Guha S, Munroe PR, Baker I (1991) Room temperature deformation behavior of multiphase Ni-20 at.% Al-30 at.% Fe and its constituent phases. Mater Sci Eng A 131(1):27–37

Misra A, Gibala R (1997) Room-temperature deformation behavior of directionally solidified multiphase Ni–Fe–Al alloys. Metall Mater Trans A 28(3):795–807

Misra A, Gibala R (2000) Plasticity in multiphase intermetallics. Intermetallics 8(9–11):1025–1034

Sauthoff G (2000) Multiphase intermetallic alloys for structural applications. Intermetallics 8(9–11):1101–1109

Liao Y, Baker I (2008) Microstructure and room-temperature mechanical properties of Fe30Ni20Mn35Al15. Mater Charact 59(11):1546–1549

Liao Y, Baker I (2011) On the room-temperature deformation mechanisms of lamellar-structured Fe30Ni20Mn35Al15. Mater Sci Eng A 528(12):3998–4008

Liao Y, Meng F, Baker I (2011) Environmental embrittlement of two-phase Fe30Ni20Mn35Al15. Intermetallics 19(10):1533–1537

Liao Y, Baker I (2011) Evolution of the microstructure and mechanical properties of eutectic Fe30Ni20Mn35Al15. J Mater Sci 46(7):2009–2017. doi:10.1007/s10853-010-5197-6

Umakoshi Y, Nakano T, Yamane T (1992) The effect of orientation and lamellar structure on the plastic behavior of TiAl crystals. Mater Sci Eng A 152(1–2):81–88

Huang L, Liaw PK, Liu CT (2007) Microstructural control of Ti–Al–Nb–W–B alloys. Metall Mater Trans A 38(13):2290–2297

Maruyama K, Yamada N, Sato H (2001) Effects of lamellar spacing on mechanical properties of fully lamellar Ti–39.4 mol%Al alloy. Mater Sci Eng A 319–321:360–363

Ramanujan RV, Maziasz PJ, Liu CT (1996) The thermal stability of the microstructure of γ-based titanium aluminides. Acta Mater 44(7):2611–2642

Hyzak JM, Bernstein IM (1976) The role of microstructure on the strength and toughness of fully pearlitic steels. Metall Trans A 7(8):1217–1224

Taleff E, Lewandowski J, Pourladian B (2002) Microstructure–property relationships in pearlitic eutectoid and hypereutectoid carbon steels. JOM 54(7):25–30

Dollar M, Bernstein IM, Thompson AW (1988) Influence of deformation substructure on flow and fracture of fully pearlitic steel. Acta Metall Mater 36(2):311–320

Liao Y (2009) Microstructure and mechanical properties of Fe55Mn19Al26 and Fe30Ni20Mn35Al15. PhD Dissertation, Dartmouth College

Schaefer AO, Council TMP (1974) Symposium on elevated temperature properties of austenitic stainless steels. American Society of Mechanical Engineers, New York

Gogia AK, Nandy TK, Banerjee D, Carisey T, Strudel JL, Franchet JM (1998) Microstructure and mechanical properties of orthorhombic alloys in the TiAlNb system. Intermetallics 6(7–8):741–748

Pang L, Kumar KS (1998) Mechanical behavior of an Fe–40Al–0.6C alloy. Acta Mater 46(11):4017–4028

Umeda H, Kishida K, Inui H, Yamaguchi M (1997) Effects of Al-concentration and lamellar spacing on the room-temperature strength and ductility of PST crystals of TiAl. Mater Sci Eng A 239–240:336–343

Liu CT, Stiegler JO (1984) Ductile ordered intermetallic alloys. Science 226(4675):636–642

Embury JD, Fisher RM (1966) The structure and properties of drawn pearlite. Acta Metall Mater 14(2):147–159

Liu CT, Schneibel JH, Maziasz PJ, Wright JL, Easton DS (1996) Tensile properties and fracture toughness of TiAl alloys with controlled microstructures. Intermetallics 4(6):429–440

Nam W, Bae C, Lee C (2002) Effect of carbon content on the Hall–Petch parameter in cold drawn pearlitic steel wires. J Mater Sci 37(11):2243–2249. doi:10.1023/A:1015361031384

Karlsson B, Lindén G (1975) Plastic deformation of eutectoid steel with different cementite morphologies. Mater Sci Eng 17(1):153–164

Marder AR, Bramfitt BL (1976) The effect of morphology on the strength of pearlite. Metall Trans A 7(3):365–372

Ray KK, Mondal D (1991) The effect of interlamellar spacing on strength of pearlite in annealed eutectoid and hypoeutectoid plain carbon steels. Acta Metall Mater 39(10):2201–2208

Friedman LH, Chrzan DC (1998) Scaling theory of the Hall–Petch relation for multilayers. Phys Rev Lett 81(13):2715–2718

Sevillano JG (1980) Strength of Metals and Alloys: ICSMA 5; Proceedings. Deformation of polycrystals, solid solution hardening, fatigue, in-situ electron microscopy during deformation, combination of elementary mechanisms, Pergamon Press, New York

Alexander DJ, Bernstein IM (1989) Cleavage fracture in pearlitic eutectoid steel. Metall Trans A 20(11):2321–2335

Sunwoo H, Fine ME, Meshii M, Stone DH (1982) Cyclic deformation of pearlitic eutectoid rail steel. Metall Trans A 13(11):2035–2047

Lewandowski JJ, Thompson AW (1986) Microstructural effects on the cleavage fracture stress of fully pearlitic eutectoid steel. Metall Mater Trans A 17(10):1769–1786

Lapin J (2003) Effect of lamellar structure on microhardness and yield stress of directionally solidified intermetallic Ti–46Al–2W–0.5Si alloy. J Mater Sci Lett 22(10):747–749

Liu ZC, Lin JP, Li SJ, Chen GL (2002) Effects of Nb and Al on the microstructures and mechanical properties of high Nb containing TiAl base alloys. Intermetallics 10(7):653–659

Cao G, Fu L, Lin J, Zhang Y, Chen C (2000) The relationships of microstructure and properties of a fully lamellar TiAl alloy. Intermetallics 8(5–6):647–653

Liu CT, Maziasz PJ (1998) Microstructural control and mechanical properties of dual-phase TiAl alloys. Intermetallics 6(7–8):653–661

Suri S, Neeraj T, Daehn GS, Hou DH, Scott JM, Hayes RW, Mills MJ (1997) Mechanisms of primary creep in α/β titanium alloys at lower temperatures. Mater Sci Eng A 234–236:996–999

Umakoshi Y, Nakano T (1993) The role of ordered domains and slip mode of α2 phase in the plastic behaviour of TiAl crystals containing oriented lamellae. Acta Metall Mater 41(4):1155–1161

Ishii H, Ohkubo K, Miura S, Mohri T (2003) Mechanical properties of alpha+kappa two-phase lamellar structure in Fe–Mn–Al–C alloy. Mater Trans 44(9):1679–1681

Darolia R (1991) NiAl alloys for high-temperature structural applications. JOM 43(3):44–49

Guha S, Baker I, Munroe PR (1996) Elevated temperature deformation behaviour of multi-phase Ni-20 at.% Al-30 at.% Fe and its constituent phases. J Mater Sci 31(15):4055–4065. doi:10.1007/BF00352668

Baker I (1995) A review of the mechanical properties of B2 compounds. Mater Sci Eng A 192–193(1):1–13

Baker I (1999) Mechanical properties of strongly-ordered B2 compounds. Trans Nonferr Metal Soc China 9:146–156

Shun TT, Du YC (2009) Microstructure and tensile behaviors of fcc Al0.3CoCrFeNi high entropy alloy. J Alloy Compd 479(12):157–160

Acknowledgements

This research was supported by the National Science Foundation (NSF) Award DMR-0905229. The views and conclusions contained herein are those of the authors and should not be interpreted as necessarily representing official policies, either expressed or implied of the NSF or the U.S. Government.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meng, F., Qiu, J. & Baker, I. Effect of Al content on the microstructure and mechanical behavior of two-phase FeNiMnAl alloys. J Mater Sci 49, 1973–1983 (2014). https://doi.org/10.1007/s10853-013-7884-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7884-6