Abstract

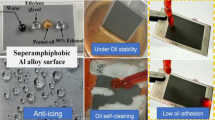

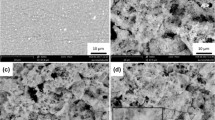

In this study, superamphiphobic (SAP) metallic aluminum (Al) alloy 2024 surfaces were produced with water and oil contact angles (CAs) of more than 150° and sliding angles of less than 10°. The two simple and environmentally friendly techniques of mechanical sanding and boiling water treatment were used to introduce micro and nanoscale roughnesses, respectively, which resulted in a hierarchical morphology. Surface energy of the rough surfaces was reduced by coating them with 1H, 1H, 2H, 2H-perfluorodecyltriethoxysilane agent. SAP property was absent for samples with micro or nanoroughness only, and it emerged only after both kinds of roughnesses were introduced. The highest CAs approaching 158° for water, 156° for ethylene glycol, and 154° for peanut oil were obtained after forming hierarchical structures involving shapes of microgrooves obtained by one-directional sanding and nanograss by immersing in boiling water for 1 min. The effects of the two approaches of random and one-directional sanding using various sandpaper grit sizes, and different time periods of treatment with boiling water on the wettability of surfaces were also investigated. In addition, fundamental wetting models were used to explain the experimental results obtained. SAP Al surfaces could see a wide range of applications in fields such as self-cleaning, anti-icing, anticorrosion, oil transportation, energy harvesting, and microfluidics.

Graphical Abstract

Similar content being viewed by others

References

Deng X, Mammen L, Butt H et al (2012) Candle soot as a template for a transparent robust superamphiphobic coating. Science 335:67–70

Tuteja A, Choi W, Ma M et al (2007) Designing superoleophobic surfaces. Science 318:1618–1622

Quéré D (2008) Wetting and roughness. Annu Rev Mater Res 38:71–99

Lafuma A, Quere D (2003) Superhydrophobic states. Nat Mater 2:457

Liu K, Jiang L (2012) Bio-inspired self-cleaning surfaces. Annu Rev Mater Res 42:231–263

Young T (1805) An essay on the cohesion of fluids. Philos Trans R Soc Lond 95:65–87

Wenzel RN (1936) Resistance of solid surfaces to wetting by water. Ind Eng Chem Res 28:988–994

Cassie ABD, Baxter S (1944) Wettability of porous surfaces. Trans Faraday Soc 40:546–551

Cheng YT, Rodak DE, Wong CA et al (2006) Effects of micro- and nano-structures on the self-cleaning behavior of lotus leaves. Nanotechnology 17:1359

Marmur A (2004) The lotus effect: superhydrophobicity and metastability. Langmuir 20:3517–3519

Patankar NA (2003) On the modeling of hydrophobic contact angles on rough surfaces. Langmuir 19:1249

Cao L, Price TP, Weiss M et al (2008) Super water- and oil-repellent surfaces on intrinsically hydrophilic and oleophilic porous silicon films. Langmuir 24:1640–1643

Tsujii K, Yamamoto T, Onda T et al (1997) Super oil-repellent surfaces. Angew Chem Int Ed Engl 36:1011

Shibuichi S, Yamamoto T, Onda T et al (1998) Super water- and oil-repellent surfaces resulting from fractal structure. J Colloid Interface Sci 208:287–294

Barthlott W, Neinhuis C (1997) Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta 202:1–8

Khedir KR, Kannarpady GK, Ishihara H et al (2011) Design and fabrication of teflon-coated tungsten nanorods for tunable hydrophobicity. Langmuir 27:4661

Gao L, McCarthy TJ (2006) A perfectly hydrophobic surface (A/R = 180/180). J Am Chem Soc 128:9052

Kim H, Noh K, Choi C et al (2011) Extreme superomniphobicity of multiwalled 8 nm TiO2 nanotubes. Langmuir 27:10191–10196

Kumar RTR, Mogensen KB, Boggild P (2010) Simple approach to superamphiphobic overhanging silicon nanostructures. J Phys Chem C 114:2936

Meng H, Wang S, Xi J et al (2008) Facile means of preparing superamphiphobic surfaces on common engineering metals. J Phys Chem C 112:11454–11458

Wu W, Wang X, Wang D et al (2009) Alumina nanowire forests via unconventional anodization and super-repellency plus low adhesion to diverse liquids. Chem Commun 9:1043–1045

Yang J, Zhang Z, Men X et al (2010) A simple approach to fabricate superoleophobic coatings. New J Chem 35:576–580

Ji Seungmuk, Ramadhianti PA, Nguyen T et al (2013) Simple fabrication approach for superhydrophobic and superoleophobic Al surface. Microelectron Eng 111:404–408

Yang J, Zhang Z, Xu X et al (2011) Superoleophobic textured aluminum surfaces. New J Chem 35:2422–2426

Liu K, Jiang L (2011) Metallic surfaces with special wettability. Nanoscale 3:825–838

Liu K, Tian Y, Jiang L (2013) Bio-inspired superoleophobic and smart materials: design, fabrication, and application. Prog Mater Sci 58:503–564

Ohkubo Y, Tsuji I, Onishi S et al (2010) Preparation and characterization of super-hydrophobic and oleophobic surface. J Mater Sci 45:4963. doi:10.1007/s10853-010-4362-2

Nilsson MA, Daniello RJ, Rothstein JP (2010) A novel and inexpensive technique for creating superhydrophobic surfaces using Teflon and sandpaper. J Phys D 43:045301

Vedder W, Vermilyea DA (1969) Aluminum + water reaction. Trans Faraday Soc 65:561–584

Alwitt RS (1971) Some physical and dielectric properties of hydrous alumina films. J Electrochem Soc 118:1730–1733

Stralin A, Hjertberg T (1993) Improved adhesion strength between aluminum and ethylene copolymers by hydration of the aluminum surface. J Appl Polym Sci 49:511–521

Rider AN, Arnott DR (2000) Boiling water and silane pre-treatment of aluminum alloys for durable adhesive bonding. Int J Adhes Adhes 20:209–220

Jafari R, Farzaneh M (2011) Fabrication of superhydrophobic nanostructured surface on aluminum alloy. Appl Phys A 102:195–199

Yang Z, Wu Y-Z, Ye Y-F, Gong M-G, Xu X-L (2012) A simple way to fabricate an aluminum sheet with superhydrophobic and self-cleaning properties. Chinese Phys B 21:126801

Hozumi A, Kim B, McCarthy TJ (2009) Hydrophobicity of perfluoroalkyl isocyanate monolayers on oxidized aluminum surfaces. Langmuir 25:6834–6840

McCarvill WT, Bell JP (1974) Effect of time and type of water pretreatment on the bond strength of epoxy-aluminum joints. J Appl Polym Sci 18:335–342

Zisman WA (1964) Relation of the equilibrium contact angle to liquid and solid constitution. In: Anonymous contact angle, wettability, and adhesion, advances in chemistry, Washington, DC

Nishino T, Meguro M, Nakamae K et al (1999) Lowest surface free energy based on -CF3 alignment. Langmuir 15:4321–4323

Hoque E, Derose JA, Kulik G et al (2006) Alkylphosphonate modified aluminum oxide surfaces. J Phys Chem B 110:10855

Lakshmi RV, Bharathidasan T, Bera P et al (2012) Fabrication of superhydrophobic and oleophobic sol–gel nanocomposite coating. Surf Coat Technol 206:3888–3894

Tuteja A, Choi W, McKinley GH et al (2008) Design parameters for superhydrophobicity and superoleophobicity. MRS Bull 33:752–758

Tuteja A, Choi W, Mabry JM et al (2008) Robust omniphobic surfaces. Proc Natl Acad Sci USA 105:18200

Daniel I, Karl WK, Prantik M et al (2013) Superhydrophobic antireflection, and low haze glass surfaces using scalable dewetting nanostructuring. Nano Res 6:429–440

Chhatre SS, Choi W, Tuteja A et al (2010) Scale dependence of omniphobic mesh surfaces. Langmuir 26:4027–4035

Ganesh VA, Dinachali SS, Nair AS et al (2013) Robust superamphiphobic film from electrospun TiO2 nanostructures. ACS Appl Mater Interfaces 5:1527–1532

Zhao H, Park K, Law K (2012) Effect of surface texturing on superoleophobicity, contact angle hysteresis, and “robustness”. Langmuir 28:14925–14934

Mishchenko L, Hatton B, Bahadur V et al (2010) Design of ice-free nanostructured surfaces based on repulsion of impacting water droplets. ACS Nano 4:7699–7707

Bahadur V, Garimella SV (2009) Preventing the Cassie–Wenzel transition using surfaces with noneommunicating roughness elements. Langmuir 25:4815–4820

Nosonovsky M, Bormashenko E (2009) In: Favret E, Fuentes N (eds) Functional properties of biological surfaces: characterization and technological applications. World Scientific Publishing, Singapore, p 43

Bhushan B, Jung YC, Koch K (2009) Nano and hierarchical structures for superhydrophobicity, self-cleaning and low adhesion. Philos Trans R Soc A 367:1631–1672

Feng L, Zhang Y, Xi J et al (2008) Petal effect: a superhydrophobic state with high adhesive force. Langmuir 24:4114–4119

Bhushan B, Nosonovsky M (2010) The rose petal effect and the modes of superhydrophobicity. Philos Trans R Soc A 368:4713–4728

Shuai Y, Yuchen Q, Yaxu H et al (2013) Peanut leaf inspired multifunctional surfaces. Small. doi:10.1002/smll.201301029

Acknowledgements

The authors would like to thank the UALR Center for Integrative Nanotechnology Sciences staff for their valuable help during SEM measurements. The editorial assistance of Dr. Marinelle Ringer is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Saifaldeen, Z.S., Khedir, K.R., Cansizoglu, M.F. et al. Superamphiphobic aluminum alloy surfaces with micro and nanoscale hierarchical roughness produced by a simple and environmentally friendly technique. J Mater Sci 49, 1839–1853 (2014). https://doi.org/10.1007/s10853-013-7872-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7872-x