Abstract

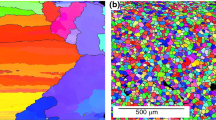

The structure, phase composition, and their thermal evolution were studied in case of ternary Al–Zn–Mg alloys before and after high-pressure torsion (HPT) in Bridgman anvils. The as-cast non-deformed alloys contained the fine particles of Mg32(Al,Zn)49 (τ phase), MgZn2 (η phase), AlMg4Zn11 (η′ phase), and Mg7Zn3 phases embedded in the matrix of Al-based solid solution. During heating in differential scanning calorimeter (DSC), all these phases dissolved around 148 °C. The τ nanoparticles coherent with (Al) matrix-formed instead around 222 °C. HPT of the as-cast alloys strongly refined the grains of (Al) solid solution from 500 μm to 120–150 nm. The particles of τ, η, η′, and Mg7Zn3 phases fully dissolved in the (Al) matrix. During the following DSC-heating, particles of η phase appeared and grew. Their amount became maximal around 166 °C. The growth of η phase in the fine-grained HPT-treated alloys instead of τ phase in the coarse-grained ones is explained by the shift of the (Al) + η/(Al) + η + τ/(Al) + τ lines in the Al–Zn–Mg ternary phase diagram due to the grain boundary (GB) adsorption. At 166 °C the η phase formed the continuous flat layers in numerous (Al)/(Al) GBs. This corresponds to the complete GB wetting by the η phase. Other (Al)/(Al) GBs contain separated lenticular η particles (incomplete GB wetting). Increasing the temperature from 166 to 320 °C led to the disappearance of the completely wetted (Al)/(Al) GBs. In other words, the transition from complete to the incomplete wetting of (Al)/(Al) GBs by the η phase proceeds between 166 °C and 320 °C.

Similar content being viewed by others

References

Furukawa M, Horita Z, Nemoto M, Valiev RZ, Langdon TG (1996) Acta Mater 44:4619

Roven HJ, Liu M, Murashkin MY, Valiev RZ, Kilmametov AR, Ungár T, Balogh L (2008) Mater Sci Forum 604:179

Cepeda-Jimenez CM, Garcia-Infanta JM, Rauch EF, Blandin JJ, Ruano OA, Carreno F (2012) Metal Mater Trans A 43:4224

Garcia-Infanta JM, Zhilyaev AP, Sharafutdinov A, Ruano OA, Carreno F (2009) J Alloys Comp 473:163

Krishna KG, Sivaprasad K, Venkateswarlu K, Kumar KCH (2012) Mater Sci Eng A 535:129

Liu FC, Ma ZY (2008) Scr Mater 58:667

Sha G, Wang YB, Liao XZ, Duan ZC, Ringer SP, Langdon TG (2009) Acta Mater 57:3123

Straumal B, Valiev R, Kogtenkova O, Zieba P, Czeppe T, Bielanska E, Faryna M (2008) Acta Mater 56:6123

Gao N, Starink MJ, Langdon TG (2009) Mater Sci Technol 25:687

Ungar T, Borbely A (1996) Appl Phys Lett 69:3173

Dean JA (1995) The analytical chemistry handbook. McGraw Hill, New York, p 151 (Standards ASTM D 3417, ASTM D 3418, ASTM E 1356, ISO 11357)

Kogtenkova OA, Protasova SG, Mazilkin AA, Straumal BB, Zięba P, Czeppe T, Baretzky B (2012) J Mater Sci 47:8367. doi:10.1007/s10853-012-6786-3

Gao N, Starink MJ, Furukawa M, Horita Z, Xu C, Langdon TG (2006) Mater Sci Forum 503:275

Straumal BB, Gust W (1996) Mater Sci Forum 207:59

Straumal BB, Gust W, Watanabe T (1999) Mater Sci Forum 294:411

Villars P, Prince A, Okamoto H (eds) (1995) Handbook of ternary alloy phase diagrams, vol 10. ASM International, Metals Park

Lu J, Yin JG, He Y, Ding BF (2005) Rare Metal Mater Eng 34:742

Malek P, Cieslar M, Islamgaliev RK (2004) J Alloys Comp 378:237

Molodov DA, Straumal BB, Shvindlerman LS (1984) Scr Metall 18:207

Straumal BB, Gornakova AS, Mazilkin AA, Fabrichnaya OB, Kriegel MJ, Baretzky B, Jiang JZ, Dobatkin SV (2012) Mater Lett 81:225

Straumal BB, Mazilkin AA, Protasova SG, Myatiev AA, Straumal PB, Baretzky B (2008) Acta Mater 56:6246

Straumal BB, Dobatkin SV, Rodin AO, Protasova SG, Mazilkin AA, Goll D, Baretzky B (2011) Adv Eng Mater 13:463

Krishna KG, Sivaprasad K, Venkateswarlu K, Kumar KCH (2012) Mater Sci Eng, A 535:129

Sha G, Ringer SP, Duan ZC, Langdon TG (2009) Int J Mater Res 100:1674

German RM, Suri P, Park SJ (2009) J Mater Sci 44:1. doi:10.1007/s10853-008-3008-0

Empl D, Felberbaum L, Laporte V, Chatain D, Mortensen A (2009) Acta Mater 57:2527

Cahn JW (1977) J Chem Phys 66:3667

Ebner C, Saam WF (1977) Phys Rev Lett 38:1486

López GA, Mittemeijer EJ, Straumal BB (2004) Acta Mater 52:4537

Straumal BB, Klinger LM, Shvindlerman LS (1984) Acta Metall 32:1355

Acknowledgements

Authors thank the Russian Foundation for Basic Research (contracts 11-03-01198 and 11-08-90439), ERA.Net RUS program (Grant STProjects-219 NanoPhase), program of bilateral cooperation between Russian and Polish Academies of sciences, the grant of President of Russian Federation for young scientists (MK-3748.2011.8) and Polish National Science Centre (Grant UMO-2011/01/M/ST8/07822) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kogtenkova, O.A., Mazilkin, A.A., Straumal, B.B. et al. Phase transformations in Al–Mg–Zn alloys during high pressure torsion and subsequent heating. J Mater Sci 48, 4758–4765 (2013). https://doi.org/10.1007/s10853-013-7266-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7266-0