Abstract

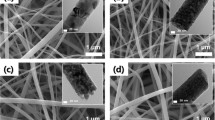

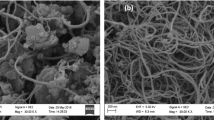

Poly(vinyl pyrrolidone) with a M w of 1.3 × 106 g/mol (PVP) or 4 × 104 g/mol (PVPLow) was used as a polymer to fabricate PVP–Pt, PVP–Pt–Cu, and PVPLow–Pt–Sn composite fibers by electrospinning. The effect of varying the electrospinning conditions on the fiber morphology was investigated, and the solution composition and electrospinning parameters were optimized to obtain composite fibers with a minimal bead formation. Pt, Pt–Cu, and Pt–Sn metal nanofibers were then obtained by heat treatment of the respective PVP–metal or PVPLow–metal composite fibers at 300, 350, and 450 °C, respectively, in air for 5 h. Single cells of a direct ethanol protonic ceramic fuel cell were subsequently fabricated by applying the metal nanofibers, or a commercial Pt paste, as the anode on the surfaces of BaY0.2Zr0.8O3−δ pellets and Pt paste as the cathode. The I–V polarization results showed that the metal nanofiber-based anode single cells provided higher maximum power densities than that of the Pt paste anode, with the Pt nanofiber-based anode single cell producing the highest maximum power density of 0.58 mW/cm2 at 550 °C.

Similar content being viewed by others

References

Tayal J, Rawat B, Basu S (2011) Int J Hydrogen Energy 36:14884. doi:10.1016/j.ijhydene.2011.03.035

Otomo J, Nishida S, Takahashi H, Nagamoto H (2008) J Electroanal Chem 615:84. doi:10.1016/j.jelechem.2007.11.019

Rousseau S, Coutanceau C, Lamy C, Léger J-M (2006) J Power Sources 158:18. doi:10.1016/j.jpowsour.2005.08.027

Song S, Wang Y, Shen P (2007) Chin J Catal 28:752. doi:10.1016/S1872-2067(07)60063-1

Cimenti M, Hill JM (2009) J Power Sources 186:377. doi:10.1016/j.jpowsour.2008.10.043

Colmati F, Antolini E, Gonzalez ER (2006) J Power Sources 157:98. doi:10.1016/j.jpowsour.2005.07.087

Kim HJ, Kim YS, Seo MH, Choi SM, Cho J, Huber GW, Kim WB (2010) Electrochem Commun 12:32. doi:10.1016/j.elecom.2009.10.029

Liu Z, Ling XY, Su X, Lee JY, Gan LM (2005) J Power Sources 149:1. doi:10.1016/j.jpowsour.2005.02.009

Purgato FLS, Pronier S, Olivi P, de Andrade AR, Léger JM, Tremiliosi-Filho G, Kokoh KB (2012) J Power Sources 198:95. doi:10.1016/j.jpowsour.2011.09.060

Nakagawa N, Kaneda Y, Wagatsuma M, Tsujiguchi T (2012) J Power Sources 199:103. doi:10.1016/j.jpowsour.2011.10.057

Jiang L, Sun G, Sun S, Liu J, Tang S, Li H, Zhou B, Xin Q (2005) Electrochim Acta 50:5384. doi:10.1016/j.electacta.2005.03.018

Tsiakaras PE (2007) J Power Sources 171:107. doi:10.1016/j.jpowsour.2007.02.005

Sieben JM, Duarte MME (2011) Int J Hydrogen Energy 36:3313. doi:10.1016/j.ijhydene.2010.12.020

Antolini E (2007) J Power Sources 170:1. doi:10.1016/j.jpowsour.2007.04.009

Zhang X, Li D, Dong D, Wang H, Webley PA (2010) Mater Lett 64:1169. doi:10.1016/j.matlet.2010.02.041

Choi SM, Kim JH, Jung JY, Yoon EY, Kim WB (2008) Electrochim Acta 53:5804. doi:10.1016/j.electacta.2008.03.041

Kim HJ, Kim YS, Seo MH, Choi SM, Kim WB (2009) Electrochem Commun 11:446. doi:10.1016/j.elecom.2008.12.027

Kim JM, Joh H-I, Jo SM, Ahn DJ, Ha HY, Hong S-A, Kim S-K (2010) Electrochim Acta 55:4827. doi:10.1016/j.electacta.2010.03.036

Kim YS, Nam SH, Shim H-S, Ahn H-J, Anand M, Kim WB (2008) Electrochem Commun 10:1016. doi:10.1016/j.elecom.2008.05.003

Zhou W-P, Li M, Koenigsmann C, Ma C, Wong SS (2011) Electrochim Acta 56:9824. doi:10.1016/j.electacta.2011.08.055

Iwahara H, Yajima T, Hibino T, Ozaki K, Suzuki H (1993) Solid State Ionics 61:65. doi:10.1016/0167-2738(93)90335-Z

Kreuer KD (2003) Annu Rev Mater Res 33:333

Fabbri E, Pergolesi D, Licoccia S, Traversa E (2010) Solid State Ionics 181:1043. doi:10.1016/j.ssi.2010.06.007

Kosasang O, Somroop K, Chindaudom P, Pornprasertsuk R (2009) ECS Trans 19:145

Pornprasertsuk R, Kosasang O, Somroop K, Horprathum N, Limnonthakul P, Chindaudom P, Jinawath S (2011) Solid State Sci 13:1429. doi:10.1016/j.solidstatesciences.2011.04.015

Pornprasertsuk R, Yuwapattanawong C, Permkittikul S, Tungtidtham T (2012) Int J Precis Eng Manuf 13:1813

Peng C, Melnik J, Li J, Luo J, Sanger AR, Chuang KT (2009) J Power Sources 190:447. doi:10.1016/j.jpowsour.2009.01.020

Babilo P, Haile SM (2005) J Am Ceram Soc 88:2362

Shui J, Li JCM (2009) Nano Lett 9:1307

Bhardwaj N, Kundu SC (2010) Biotechnol Adv 28:325. doi:10.1016/j.biotechadv.2010.01.004

Huang Z-M, Zhang Y-Z, Kotaki M, Ramakrishna S (2003) Compos Sci Technol 63:2223. doi:10.1016/S0266-3538(03)00178-7

Zong X, Kim K, Fang D, Ran S, Hsiao BS, Chu B (2002) Polymer 43:4403. doi:10.1016/S0032-3861(02)00275-6

Kittel C (1996) Introduction to solid state physics, 7th edn. Wiley Inc., New York, p 78

Acknowledgements

The authors would like to thank Asst. Prof. Dr. Thanakorn Wasanapianpong for his assistance on the processing equipment; Wirapong Kornpanom, Thanakorn Tepamart and Boonleau Ngaotawornchai for the XRD, SEM and TEM analysis; Mana Rodchome, Dr. Sumittra Charojrochkul and Pranuda Jivaganont (National Metal and Materials Technology Center) for the help with the cold isostatic pressing equipment, fuel cell test station and high temperature furnace; and Dr. Robert Butcher for the suggestion on the manuscript preparation. The authors acknowledge the financial support from the Research, Development and Engineering (RD&E) fund through The National Nanotechnology Center (NANOTEC), The National Science and Technology Development Agency (NSTDA), Thailand (Project No. P-11-00984) to Chulalongkorn University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yaipimai, W., Pornprasertsuk, R. Fabrication of Pt, Pt–Cu, and Pt–Sn nanofibers for direct ethanol protonic ceramic fuel cell application. J Mater Sci 48, 4059–4072 (2013). https://doi.org/10.1007/s10853-013-7218-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-013-7218-8