Abstract

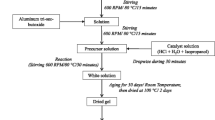

Powder granulation, Ti-doping and thermal post-treatment have beneficial effects on the electrochemical performance of 5 V LiNi0.5Mn1.5O4 (LNMO) spinel materials. It is shown that spray-drying combined with a post-doping process step is suitable to prepare Ti-doped 5 V materials with a defined and highly reproducible microstructure and chemical composition. Powder granulation via spray-drying and thermal post-treatment provides spherical LNMO granules with nano-crystalline primary particles and a 10 % higher specific discharge capacity compared to pristine LNMO materials due to the presence of the partially ordered P4 3 32 spinel phase and the reduced Mn3+ content. Powder granulation combined with a post-doping process step which utilizes titanium containing sol leads to spherical LiNi0.5Mn1.47Ti0.03O4 granules with uniform nano-crystalline primary particles and a homogenous Ti distribution. The second calcination process after spray-drying as well as the Ti-doping cause a reduced content of the Li x Ni1−x O impurity phase. This facile sol–gel processing leads to doped LiNi0.5Mn1.47Ti0.03O4 with an increased discharge capacity of 18 % compared to the original material. All the granulated materials show a good rate performance up to 10 C due to their particular microstructure.

Similar content being viewed by others

References

Liu GQ, Wen LY, Liu M (2010) J Solid State Electrochem 14:2191

Goodenough JB, Kim Y (2010) Chem Mater 22:587

Manthiram A (2011) J Phys Chem Lett 2:176

Xu B, Qian D, Wang Z, Meng YS (2012) Mater Sci Eng R Rep 73:51

Zhong Q, Bonakdarpur A, Zhang M, Gao Y, Dahn JR (1997) J Electrochem Soc 144:205

Borgel V, Markevich E, Aurbach D, Semrau G, Schmidt M (2009) J Power Sources 189:331

Yi T-F, Xie Y, Ye M-F, Jiang L-J, Zhu R-S, Zhu Y-R (2011) Ionics 17:383

Wu YP, Rahm E, Holze R (2002) Electrochim Acta 47:3491

Alcántara R, Jaraba M, Lavela P, Tirado JL (2003) Chem Mater 15:2376

Kum J-H, Myung S-T, Yoon CS, Oh I-H, Sun Y-K (2004) J Electrochem Soc 151(11):A1911

Santhanam R, Rambabu B (2010) J Power Sources 195:5442

Sun Y, Yang Y, Zhan H, Shao H, Zhou Y (2010) J Power Sources 195:4322

Hwang BJ, Wu YW, Venkateswarlu M, Cheng MY, Santhanam R (2009) J Power Sources 193:828

Li D, Ito A, Kobayakawa K, Noguchi H, Sato Y (2006) J Power Sources 161:1241

Hernán L, Morales J, Sánchez L, Santos J (1999) Solid State Ion 118:179

Noguchi T, Yamazaki I, Numata T, Shirakata MJ (2007) J Power Sources 174:359

Liu GQ, Yuan WS, Tian YW (2009) J Alloys Compd 484:567

Xiong L, Xu Y, Tao T, Goodenough JB (2012) J Power Sources 199:214

Livage J, Sanchez C, Babonneau F (1998) Molecular precursor routes to inorganic solids. In: Interrante LV, Hampden-Smith MJ (eds) Chemistry of advanced materials: an overview (Ch. 9). Wiley-VCH, New York

Schubert U, Hüsing N (2012) Synthesis of inorganic materials (Ch. 4). Wiley-VCH, Weinheim

Boyle TJ, Schwartz RW (1994) Comments Inorg Chem 16(5):243

Ceder G (2012) MRS Bull 35:693

Marom R, Amalraj SF, Leifer N, Jacob D, Aurbach D (2011) J Mater Chem 21:9938

Bach S, Pereira-Ramos JP, Baffier NJ (1998) Mater Chem 8(1):251

Le M-L-P, Strobel P, Colin CV, Pagnier T, Alloin F (2011) J Phys Chem Solids 72:124

TOPAS version 4.2. Bruker AXS, Karlsruhe

Parry KL, Shard AG, Short RD, White RG, Whittle JD, Wright A (2006) Surf Interface Anal 38:1497

Baddour-Hadjean R, Pereira-Ramos J-P (2010) Chem Rev 110:1278

Amdouni N, Zaghib K, Gendron F, Mauger A, Julien CM (2006) Ionics 12:117

Bhaskar A, Bramnik N, Senyshyn A, Fuess H, Ehrenberg HJ (2010) Electrochem Soc 157(6):A689

Biesinger MC, Lau LWM, Gerson AR, Smart RSC (2010) Appl Surf Sci 257:887

Kim J-H, Myung S-T, Yoon CS, Kang SG, Sun Y-K (2004) Chem Mater 16:906

Aklalouch M, Amarilla JM, Rojas RM, Saadoune I, Rojo JM (2010) Electrochem Commun 12:548

Shaju KM, Bruce PG (2008) Dalton Trans 40:5471

Lee H-W, Muralidharan P, Mari CM, Ruffo R, Kim DK (2011) J Power Sources 196:10712

Li D, Ito A, Kobayakawa K, Noguchi H, Sato Y (2007) Electrochim Acta 52:1919

Liu J, Manthiram A (2009) J Phys Chem C 113:15073

Xiao J, Chen X, Sushko PV, Sushko ML, Kovarik L, Feng J, Deng Z, Zheng J, Graff GL, Nie Z, Choi D, Liu J, Zhang J-G, Whittingham MS (2012) Adv Mater 24:2109

Bruce PG (ed) (1995) Chemistry of solid state materials, solid state electrochemistry (Ch. 3, 7, 8). Cambridge University Press, Cambridge

Acknowledgements

The authors would like to thank the Federal Ministry of Education and Research (BMBF) and the Ministry of Science, Research and Arts Baden-Württemberg (MWK) for financial support. The authors are grateful for the invaluable support of this work by Florian Stemme (IAM-WPT, SEM images of the spinel powders) and Dr. Thomas Bergfeldt (IAM-AWP, extensive ICP analysis to reveal the exact chemical composition of the spinel materials). Finally the authors would like to acknowledge the help provided by Dr. Stephen Doyle during the data collection at ANKA PDIFF.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Schroeder, M., Glatthaar, S., Geßwein, H. et al. Post-doping via spray-drying: a novel sol–gel process for the batch synthesis of doped LiNi0.5Mn1.5O4 spinel material. J Mater Sci 48, 3404–3414 (2013). https://doi.org/10.1007/s10853-012-7127-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-7127-2