Abstract

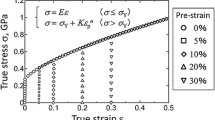

We evaluate representative stress and strain of austenitic stainless steels using instrumented indentation tests with a spherical indenter by taking into account the real contact depth and effective radius. We investigate the relation between material pileup underneath the spherical indenter and the strain-hardening exponent in uniaxial tensile tests for these steels. We evaluate the suitability of three constitutive equations, the Hollomon, Ludwigson, and Swift equations, for describing linear-type strain-hardening of austenitic stainless steels. Using the real contact depth and effective radii developed for the austenitic stainless steels, we find good agreement between representative stress and strain in instrumented indentation and uniaxial tensile tests.

Similar content being viewed by others

References

Oliver WC, Pharr GM (1992) J Mater Res 7:1564

Kim JY, Lee KW, Lee JS, Kwon D (2006) Surf Coat Technol 201:4278

Bouzakis KD, Michailidis N (2004) Thin Solid Films 469:227

Tyulyukovskiy E, Huber N (2006) J Mater Res 21:664

Klötzer D, Ullner C, Tyulyukovskiy E, Huber N (2006) J Mater Res 21:677

Lee YH, Kim Y, Park JS, Lee HM (2010) Nanosci Nanotechno Lett 2:337

Choi IC, Yoo BG, Kim YJ, Seok MY, Wang YM, Jang JI (2011) Scripta Mater 65:300

Lee YH, Park JS, Lee HM, Nahm SH (2010) Int J Mod Phys B 24:2453

Lee KW, Kim KH, Kim JY, Kwon D (2008) J Phys D Appl Phys 41:074014

Jang JI (2009) J Ceram Process Res 10:391

Tabor D (1951) Hardness of metals. Clarendon Press, Oxford

Ahn JH, Kwon D (2001) J Mater Res 16:3170

Kim SH, Lee BW, Choi Y, Kwon D (2006) Mater Sci Eng A Struct 415:59

Kang SK, Kim JY, Park CP, Kim HU, Kwon D (2010) J Mater Res 25:337

Malzbender J, de With G (2002) J Mater Res 17:502

Cheng YT, Cheng CM (1999) Int J Solids Struct 36:1231

Choi Y, Lee HS, Kwon D (2004) J Mater Res 19:3307

Alcalà J, Barone AC, Anglada M (2000) Acta Mater 48:3451

Bartier O, Hernot X, Mauvoisin G (2010) Mech Mater 42:640

Kang SK, Kim JY, Kang I, Kwon D (2009) J Mater Res 24:2965

ASTM E8-04 (2004) Standard test methods for tension testing of metallic materials. ASTM International, West Conshohocken

Hollomon JH (1945) Trans Metall Soc AIME 162:268

Kleemola HJ, Nieminen MA (1974) Metall Mater Trans 5:1863

Ludwigson DC (1971) Metall Mater Trans 2:2825

Swift HW (1952) J Mech Phys Solids 1:1

Samuel KG, Rodriguez P (2005) J Mater Sci 40:5727. doi:10.1007/s10853-005-1078-9

Yoo JD, Park KT (2008) Mater Sci Eng A 496:417

Acknowledgements

This work was supported by the National Research Foundation of Korea (NRF) grant funded by the Korea government (MEST) (0417-20110083).

Author information

Authors and Affiliations

Corresponding author

Additional information

Young-Cheon Kim and Seung-Kyun Kang contributed equally to this study.

Rights and permissions

About this article

Cite this article

Kim, YC., Kang, SK., Kim, JY. et al. Contact morphology and constitutive equation in evaluating tensile properties of austenitic stainless steels through instrumented spherical indentation. J Mater Sci 48, 232–239 (2013). https://doi.org/10.1007/s10853-012-6733-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6733-3