Abstract

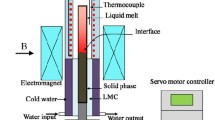

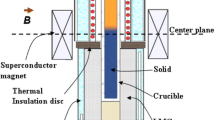

Al-0.85wt%Cu and Al-2.5wt%Cu alloys were directionally solidified under different transverse magnetic field (TMF) intensities to investigate the influence of TMF on the liquid/solid interface shape with respect to the various length scales appearing (planar, cellular, and dendritic interfaces). Results show that planar and cellular interfaces tilt to one side and then level off with increasing TMF although the dendritic interface appears not to behave in this manner. In situ synchrotron X-ray imaging was applied during directional solidification of the Al-4wt%Cu alloy under a 0.08T TMF, revealing leveling of the initially sloped interface. Solute redistribution, caused by thermoelectric magnetic convection (TEMC), responds to the changes in the interface shape. Because different typical length scales should be used in estimating the velocity of TEMC for planar, cellular, and dendritic interfaces, the maximum velocity of the convection ahead of the interface is obtained under different TMF intensities; correspondingly, leveling of the interface’s degree of slop varies with TMF.

Similar content being viewed by others

References

Trivedi R, Miyahara H, Mazumder P, Simsek E, Tewari SN (2001) J Cryst Growth 222:365

Trivedi R, Liu S, Mazumder P, Simsek E (2001) Sci Tech Adv Mater 2:309

Rutter JE, Chalmers B (1953) Can J Phys 31:15

Mullins WW, Sekerka RF (1964) J Appl Phys 35:444

Szekely J, Chhebra PS (1970) Metall Mater Trans A 1:1195

Chang CE, Wilcox WR (1974) J Cryst Growth 21:135

Burden MH, Hebditch DJ, Hunt JD (1973) J Cryst Growth 20:121

Zawilski KT, Custodio MCC, Dematlei RC, Feigelson RS (2005) J Cryst Growth 282:236

Elmahallawy NA, Farag MM (1978) J Cryst Growth 44:251

Arafune K, Kodera K, Kinoshita A, Hirata A (2003) J Cryst Growth 249:429

Tanasie C, Vizman D, Friedrich J (2011) J Cryst Growth 318:293

Chedzey HA, Hurle DTJ (1966) Nature 210:933

Bottinger WJ, Biancaniello FS, Coriell SR (1981) Metall Trans A 12:321

Tewari SN, Shah R, Song H (1994) Metall Mater Trans A 25:1535

Alboussiere T, Moreau R, Compte D (1991) Rendu de l’Acad Sci 313:749

Laskar O (1994) Ph.D Thesis. INPG, Grenoble

Li X, Gagnoud A, Ren ZM, Fautrelle Y, Moreau R (2009) Acta Mater 57:2180

Li X, Ren ZM, Gagnoud A, Budenkova O, Fautrelle Y (2011) Metall Mater Trans A 42:3459

Li X, Ren ZM, Cao GH, Gagnoud A, Fautrelle Y (2011) Mater Lett 65:3340

Yuan GZ, Ren WL, Ren ZM, Zhong YB, Li CJ, Fan YF et al (2011) Mater Sci Eng 27:012048

Bogno A, Reinhart G, Buffet A et al (2011) J Cryst Growth 318:1134

Schaefer RJ, Coriell SR (1984) Metall Trans A 15:2109

Utech HP, Flemings MC (1966) J Appl Phys 37:2021

Shercliff JA (1979) J Fluid Mech 91:231

Lehmann P, Moreau R, Camel D, Bolcato R (1998) Acta Metall 46:4067

Walter M, Walpwski J, Zbarsky V et al (2011) Nature Mater 10:742

Acknowledgements

This work is partly supported by the CNRS/ANR OPTIMAG project, the Natural Science Foundation of China (No. 50911130365) and the National 973 Project (No. 2011CB610404). The authors are indebted to Prof. Claude Esling at LETAM/CNRS-UMR, Metz, for helpful and fruitful discussions, Dr. Tamzin Lafford and Mr. Xavier Guichard at ESRF, Grenoble, for help with experiments, Dr. Simona Epure in our laboratory and Dr. Yangyang Fan at Worcester Polytechnic Institute, USA, their for fruitful help.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, J., Ren, Z., Fautrelle, Y. et al. Modification of liquid/solid interface shape in directionally solidifying Al–Cu alloys by a transverse magnetic field. J Mater Sci 48, 213–219 (2013). https://doi.org/10.1007/s10853-012-6730-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6730-6