Abstract

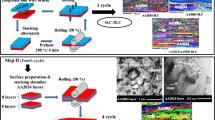

Accumulative roll bonding of two aluminium alloys, AA2219 and AA5086 was carried out up to 8 passes. During the course of ARB, the deformation inhomogeneity between the two alloy layers results in interfacial instability after the 4th pass, necking of the AA5086 layers after the 6th pass and fracture along the necked regions after the 7th and 8th pass. The EBSD analysis shows deformation bands along the interfaces after 8 passes of ARB. The ARB-processed materials predominantly show characteristic deformation texture components. The weak texture after the 2nd pass results from the combination of a weakly-textured starting AA2219 layer and a strongly-textured starting AA5086 layer. A strong deformation texture forms due to the high imposed strain after a higher number of ARB passes. Subgrain formation and related shear banding induces copper/S components in the case of the small elongated grains, while planar slip leads to the formation of brass component in the large elongated grains.

Similar content being viewed by others

Notes

QUANTA 200, FEI, The Netherlands.

Sigma Scan Pro®, Systat Software, Inc., USA.

FEG-SEM, Sirion XL-40, FEI, The Netherlands.

Struers A/S, Germany.

TSL Crystallography, AMETEK Inc., USA.

X’PertPro, PANalytical, The Netherlands.

ZHV1 microVickers hardness testing instrument, Zwick GmbH & Co. KG, Germany.

D8 Discover with GADDs, Bruker AXS, Germany.

LaboTex, LaboSofts.c., Poland.

References

Williams JC, Starke EA Jr (2003) Acta Mater 51:5775

Valiev RZ, Langdon TG (2006) Prog Mater Sci 51:881

Skrotzki W, Scheerbaum N, Oertel C-G, Brokmeier H-G, Suwas S, Tóth LS (2006) Mater Sci Forum 503–504:99

Richert J, Richert M (1986) Aluminium 62:604

Suwas S, Toth LS, Fundenberger J-J, Eberhardt A (2005) Solid State Phenom 105:357

Skrotzki W, Scheerbaum N, Oertel C-G, Brokmeier H-G, Suwas S, Tóth LS (2007) Acta Mater 55(7):2211

Suwas S, Arruffat-Massion R, Tóth LS, Fundenberger J-J, Beausir B (2009) Mater Sci Eng A 520:134

Sakai G, Horita Z, Langdon TG (2005) Mater Sci Eng A 393:344

Yin J, Lu J, Ma H, Zhang P (2004) J Mater Sci 39:2851. doi:10.1023/B:JMSC.0000021463.83899.b3

Saito Y, Tsuji N, Utsunomiya H, Sakai T, Hong RG (1998) Scripta Mater 39:1221

Tsuji N, Iwata T, Sato M, Fujimoto S, Minamino Y (2004) Sci Tech Adv Mater 5:173

Xing ZP, Kang SB, Kim HW (2002) J Mater Sci 37:717. doi:10.1023/A:1013879528697

Tsuji N, Shiotsuki K, Utsunomiya H, Saito Y (1999) Mater Sci Forum 304:73

Lee SH, Saito Y, Sakai T, Utsunomiya H (2002) Mater Sci Eng A 325:228

Hidalgo P, Cepeda-Jiménez CM, Ruano OA, Carreño F (2010) Metall Mater Trans A 41:758

Karlik M, Homolaa P, Slámová M (2004) J Alloys Compd 378:322

Wei KX, Wei W, Du QB, Hu J (2009) Mater Sci Eng A 525:55

Ghosh-Chowdhury S, Srivastava VC, Ravikumar B, Soren S (2006) Scripta Mater 54:1691

Ghosh-Chowdhury S, Dutta A, Ravikumar B, Kumar (2006) Mater Sci Eng A 428:351

Kim H-W, Kang S-B, Tsuji N, Minamino Y (2005) Acta Mater 53:1737

Quadir MZ, Ferry M, Munroe PR (2011) Scripta Mater 64:1106

Eizadjou M, Kazemi-Talachi A, Danesh-Manesh H, Shakur-Shahabi H, Janghorban K (2008) Compos Sci Technol 68:2003

Wu K, Chang H, Maawad E, Gan WM, Brokmeier HG, Zheng MY (2010) Mater Sci Eng A 527:3073

Mozaffari A, Danesh-Manesh H, Janghorban K (2010) J Alloys Compd 489:103

Min G, Lee J-M, Kang S-B, Kim H-W (2006) Mater Letters 60:3255

Yang D, Cizek P, Hodgson P, Wen C (2010) Scripta Mater 62:321

Danesh-Manesh H, Shakur-Shahabi H (2009) J Alloys Compd 476:292

Topic I, Höppel HW, Staud D, Merklein M, Geiger M, Göken M (2008) Adv Eng Mater 10:1101

Topic I, Höppel HW, Göken M (2008) J Mater Sci 43:7320. doi:10.1007/s10853-008-2754-3

Topic I, Höppel HW, Göken M (2009) Mater Sci Eng A 503:163

Topic I, Höppel HW, Göken M (2008) Mater Sci Forum 584–586:833

Scharnweber J, Skrotzki W, Oertel C-G, Brokmeier H-G, Höppel HW, Topic I, Jaschinski J (2010) Adv Eng Mater 12:989

Hausöl T, Höppel HW, Göken M (2010) J Mater Sci 45:4733. doi:10.1007/s10853-010-4678-y

Hausöl T, Höppel HW, Göken M (2010) Mater Sci Forum 667–669:217

Venkatachalam P, Roy S, Ravisankar B, Paul V, Vijayalakshmi M, Suwas S (2011) J Mater Sci 46:6518. doi:10.1007/s10853-011-5598-1

Sarkar A, Roy S, Suwas S (2011) Mater Charact 62:35

Roy S, Dhinwal SS, Suwas S, Kumar S, Chattopadhyay K (2011) Mater Sci Eng A 528:8469

Ray RK (1995) Acta Metall Mater 43(10):3861

Leffers T, Ray RK (2009) Prog Mater Sci 54:351

Hirsch J, Lücke K (1988) Acta Metall Mater 36:2863

Engler O, Hirsch J, Lücke K (1989) Acta Metall 37:2743

Panchanadeeswaran S, Field DP (1995) Acta Metall Mater 43:1683

Duckham A, Knutsen RD, Engler O (2001) Acta Mater 49:2739

Liu WC, Morris JG (2005) Scripta Mater 52:1317

Engler O, Lücke K (1992) Scripta Metall 27:1527

Vatne HE, Shahani R, Nes E (1996) Acta Mater 44:4447

Liu WC, Man CS, Raabe D, Morris JG (2005) Scripta Mater 53:1273

Raabe D (1995) Acta Metall Mater 43:1023

Eizadjou M, Danesh-Manesh H, Janghorban K (2009) J Alloys Compd 474:406

Pirgazi H, Akbarzadeha A (2009) Mater Sci Technol 25(5):625

Hatch JE (2005) Aluminium: properties and physical metallurgy. ASM International, Metals Park

Roy S, Nataraj BR, Suwas S, Kumar S, Chattopadhyay K (2012) Mater Des 36:529

Zander J, Sandström R, Vitos L (2007) Compos Mater Sci 41:86

Ebrahimi F, Ahmed Z, Li H (2004) Appl Phys Lett 85:3749

Ghosh-Chowdhury S (2005) Scripts Mater 52:99

Humphreys FJ (1997) Acta Mater 45:4231

Davies CKL, Sagar V, Stevens RN (1973) Acta Metall 21:1343

Mahesh S (2006) Acta Mater 54:4565

Huang X, Hansen N (1997) Scripts Mater 37:1

Heason CP, Prangnell PB (2002) Mater Sci Forum 408–412:733

Cao F, Cerreta EK, Trujillo CP, Gray GT III (2008) Acta Mater 56:5804

Roy S, Suwas S, Tamirisakandala S, Srinivasan R, Miracle DB (2012) Mater Sci Eng A 540:152

Morii K, Mecking H, Nakayama Y (1985) Acta Metall 33:379

Shih-Chin C, Duen-Huei H, Yun-Kie C (1989) Acta Metall 37:2031

Hosford WF (2005) Mechanical behavior of materials. Cambridge University Press, New York

Acknowledgements

The authors would like to thank The Boeing Company, USA, for providing the financial support and the required material for the present study. The Institute Nano-science Initiative (INI) and Institute X-ray Facility at Indian Institute of Science, Bangalore, India are also acknowledged for providing the research facilities related to this study. We are grateful to Dr. K. K. Sankaran of The Boeing Company for his help and support during all stages of this study. The assistance offered by Mr. Subhasis Sinha, Mr. Arun Dinesh P. and Mr. Suhas Karanth during various experiments is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Roy, S., Nataraj, B.R., Suwas, S. et al. Microstructure and texture evolution during accumulative roll bonding of aluminium alloys AA2219/AA5086 composite laminates. J Mater Sci 47, 6402–6419 (2012). https://doi.org/10.1007/s10853-012-6567-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6567-z