Abstract

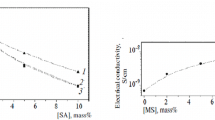

In this paper, the feasibility of fabricating polypropylene (PP) nanofibres was investigated using conductive additives such as sodium oleate (SO) and sodium chloride (NaCl) during melt-electrospinning. PP of high melt flow index (MFI = 2000) was used with varying amounts of additives. The effects of amount of additives on the fibre diameter and morphology were investigated. The lowest fibre diameters of 0.371 ± 0.106 and 0.310 ± 0.102 μm were achieved with 7 % SO and 5 % NaCl, respectively. The fabrication of nanofibres was attributed to the increase in the electrical conductivity with the introduction of the additives. The increase in the electrical conductivity was greater in the case of NaCl, due to the smaller ionic size of NaCl. Differential scanning calorimetry results showed complex melting behaviour during the heating cycles for the fibres containing SO; and double melting peaks during the second heating cycle for the fibres containing NaCl. X-ray diffraction studies showed the fibres fabricated with the additives contained lower degrees of crystallinity compared to the as-spun fibre and the crystallinity was increased after annealing. The fibres fabricated with the additives contained α-form crystals only which did not change after annealing. The fibres fabricated from pure polymer and with the additives were hydrophobic in nature. The hydrophobicity was marginally decreased with the addition of SO and NaCl.

Similar content being viewed by others

References

Ramakrishna S (2005) An introduction to electrospinning and nanofibers. World Scientific Pub Co Inc, Singapore

Nayak R, Padhye R, Kyratzis IL, Truong Y, Arnold L (2011) Textile Res J. doi:10.1177/0040517511424524

Liu Y, Deng R, Hao M, Yan H, Yang W (2010) Polym Eng Sci 50(10):2074. doi:10.1002/pen.21753

Larrondo L, St John Manley R (1981) J Polym Sci 19(6):909

Larrondo L, St John Manley R (1981) J Polym Sci 19(6):921

Larrondo L, St John Manley R (1981) J Polym Sci 19(6):933

Ogata N, Lu G, Iwata T, Yamaguchi S, Nakane K, Ogihara T (2007) J Appl Polym Sci 104:1368

Ogata N, Yamaguchi S, Shimada N, Lu G, Iwata T, Nakane K, Ogihara T (2007) J Appl Polym Sci 104(3):1640

Zhou H, Green T, Joo Y (2006) Polymer 47(21):7497

Lin T, Wang H, Wang X (2004) Nanotechnology 15:1375

Zong X, Kim K, Fang D, Ran S, Hsiao BS, Chu B (2002) Polymer 43(16):4403

Inai R, Kotaki M, Ramakrishna S (2005) Nanotechnology 16:208

Liang S, Hu D, Zhu C, Yu A (2002) Chem Eng Technol 25(4):401

Ferrer-Balas D, Maspoch ML, Martinez A, Santana O (2001) Polymer 42(4):1697

Kirshenbaum I, Wilchinsky Z, Groten B (1964) J Appl Polym Sci 8(6):2723

Krupa I, Luyt A (2001) Polym Degrad Stab 72(3):505

Wochowicz A, Eder M (1984) Polymer 25(9):1268

Scholte TG, Meijerink N, Schoffeleers H, Brands A (1984) J Appl Polym Sci 29(12):3763

Frost K, Kaminski D, Kirwan G, Lascaris E, Shanks R (2009) Carbohydr Polym 78(3):543

Farrow G, Preston D (1960) Br J Appl Phys 11:353

Hutmacher DW, Dalton PD (2011) Chem Asian J 6(1):44

Góra A, Sahay R, Thavasi V, Ramakrishna S (2011) Polym Rev 51(3):265

Kim D, Yoshino K (2000) J Phys D Appl Phys 33:464

Tandon P, Neubert R, Wartewig S (2000) J Mol Struct 526(1):49

Broda J, Wochowicz A (2000) Eur Polymer J 36(6):1283

Machado G, Denardin E, Kinast E, Gonçalves M, De Luca M, Teixeira S, Samios D (2005) Eur Polymer J 41(1):129

Chung T, Lee S (1997) J Appl Polym Sci 64(3):567

Cho D, Zhou H, Cho Y, Audus D, Joo YL (2010) Polymer 51(25):6005

Acknowledgements

The technical support from Muthu Pannirselvam and Mike Allan (Rheology and Materials Processing Centre, School of Civil, Environmental & Chemical Engineering, RMIT University); Phil Francis, Peter Rummel, Matthew Field and Frank Antolasic (School of Applied Sciences, RMIT University); Gary Peeters and Lance Nichols (MSE, CSIRO, Clayton); Mark Greaves and John Ward (Scanning Electron Microscopy, Digital Imaging & Surface Analysis Facility of MSE, CSIRO, Clayton); Birendra Singh, Mark Hickey, Jacinta Poole, Tim Hughes, Russell Varley and Wendy Tian (MSE, CSIRO, Clayton); Liz Goodall and Winston Liew (Materials Characterisation Services of MSE, CSIRO, Clayton); and David Sutton and Peter Kouwenoord (Lyondellbasell) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nayak, R., Kyratzis, I.L., Truong, Y.B. et al. Melt-electrospinning of polypropylene with conductive additives. J Mater Sci 47, 6387–6396 (2012). https://doi.org/10.1007/s10853-012-6563-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6563-3