Abstract

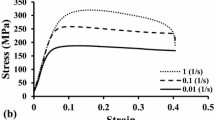

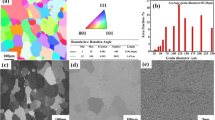

Hot compression tests of the commercial Inconel 625 were performed in the temperature range of 950–1200 °C and strain rate range of 0.01–10 s−1. The flow behavior and processing maps were investigated using the corrected flow stress data to eliminate effects of the friction and adiabatic heating. The processing maps have exhibited a domain in the temperature range of 1100–1200 °C and strain rate range of 0.01–10 s−1 corresponding to the higher efficiency of power dissipation. Microstructural observations reveal that the full dynamic recrystallization (DRX) occurs in this domain, which is optimum processing window for hot working to obtain a homogeneous microstructure. DRX grain growth occurs in the temperature range of 1150–1200 °C and strain rate range of 0.01–0.1 s−1. In view of the refined and uniform grains obtained by hot deformation, the finish forming processing should be selected the deformation conditions in which the full DRX occurs without the grain growth. The small regimes of flow instability are noticed at temperature below about 970 °C at the different strains. The material undergoes flow instability manifesting as bands of flow localizations and high density deformation twins. In addition, it is found that the undissolved second-phase particles and carbides can promote the DRX processing and be helpful to restrict the DRX grain growth.

Similar content being viewed by others

References

Shankar V, Bhanu Sankara Rao K, Mannan SL (2001) J Nucl Mater 288:222

Ahmad M, Akhter JI, Shahzad M, Akhtar M (2008) J Alloys Compd 457:131

Kumar A, Rajkumar KV, Jayakumar T, Raj B, Mishra B (2006) J Nucl Mater 350:284

Cai DY, Xiong LY, Liu WC, Sun GD, Yao M (2007) Mater Charact 58:941

Park NK, Kim IS, Na YS, Yeom JT (2001) J Mater Process Technol 111:98

Aghaie-Khafri M, Golarzi N (2008) Mater Sci Eng A 486:641

Medeiros SC, Prasad YVRK, Frazier WG, Srinivasan R (2000) Mater Sci Eng A 293:198

Li DF, Guo QG, Guo SL, Peng HJ, Wu ZG (2011) Mater Des 32:696

Guo QG, Li DF, Guo SL, Peng HJ, Hu J (2011) J Nucl Mater 414:440

Srinivasan N, Prasad YVRK, Ramarao P (2008) Mater Sci Eng A 476:146

Prasad YVRK (2003) J Mater Eng Perform 12:638

Ziegler H (1963) Prog Solid Mech 4:63

Sui FL, Xu LX, Chen LQ, Liu XH (2011) J Mater Process Technol 211:433

Wang Y, Zhen L, Shao WZ, Yang L, Zhang XM (2009) J Alloys Compd 474:341

Narayana Murty VS, Nageswara Rao B (2000) Scand J Metall 29:146

Guo SL, Li DF, Peng HJ, Guo QM, Hu J (2011) J Nucl Mater 410:52

Srinivasa N, Prasad YVRKJ (1995) Mater Process Technol 51:171

Liu Y, Hu R, Li JS, Kou HC, Li HW, Chang H, Fu HZ (2009) J Mater Process Technol 209:4020

Medeiros SC, Frazier WG, Prasad YVRK (2000) Metall Mater Trans A 31:2000

Monajati H, Jahazi M, Yue S, Taheri AK (2005) Metall Mater Trans A 36:895

Li HZ, Wang HJ, Zeng M, Liang XP, Liu HT (2011) Compos Sci Technol 71:925

Ebrahimi R, Najafizadeh A (2004) J Mater Process Technol 152:136

Goetz RL, Semiatin SL (2001) J Mater Eng Perform 10:710

Li L, Zhou J, Duszczyk J (2006) J Mater Process Technol 172:372

Akihiko C, Sang-Hak L, Hiroaki M, Mitsuru N (2009) Mater Sci Eng A 513:286

Acknowledgements

This work was co-funded by The National Natural Science Foundation of China and Baoshan Iron & Steel Co., Ltd (No. 50834008).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Guo, S., Li, D., Guo, Q. et al. Investigation on hot workability characteristics of Inconel 625 superalloy using processing maps. J Mater Sci 47, 5867–5878 (2012). https://doi.org/10.1007/s10853-012-6488-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-012-6488-x