Abstract

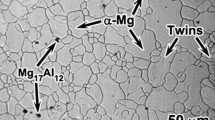

Microstructure evolution and deformation mechanisms of AZ31 magnesium alloy tubes during bending have been investigated. Dislocation slip appears to be the main deformation mechanism, along with a few {10–12} [−1011] extension twins at the outer bend radius which undergoes tensile deformation. In contrast, the material in the tube wall at the inner bend radius of the tube, which undergoes compression, deforms mainly by extension twinning. This understanding of deformation mechanisms has explain the optimum bending temperature of 150–200 °C for the AZ31 tubes where both slip and twinning are active.

Similar content being viewed by others

References

Mordike BL, Ebert T (2001) Mater Sci Eng A 302:37

A.A. Luo (2005) Journal of Materials and Manufacturing (SAE, Warrendale, PA, U.S.A, 2005): 411–421

Luo AA (2002) J Met 54(2):42

Luo AA, Sachdev AK (2004) Magnesium technology. The Minerals Metals and Materials Society, Warrendale, p 79

Yang J, Jeon B, Oh S (2001) J Mater Process Technol 111:175

Agnew SR, Duygulu Ö (2005) Int J Plasticity 21:161

Yi SB, Zaefferer S, Brokmeier H-G (2006) Mater Sci Eng A 424:275

A.A. Luo, A.K. Sachdev (2005) Materials Science Forum :488–489

Luo AA, Sachdev AK (2005) Magnesium technology. TMS, Warrendale, p 145

Wu WY, Zhang P, Zeng XQ, Jin L, Yao SS, Luo AA (2008) Mater Sci Eng A 486:596

Wang Y, Jin L, Zeng X, Luo A, Sachdev A, Mishra R (2008) Magnesium technology. The Minerals, Metals and Materials Society, New Orleans, p 165

Jiang L, Jonas JJ, Mishra RK, Luo AA, Sachdev AK, Godet S (2007) Acta Mater 55(11):3899

Jiang L, Jonas JJ, Boyle K, Martin P (2008) Mater Sci Eng A 492:68

Keshavarz Z, Barnett MR (2006) Scripta Mater 55:915

Honeycombe RWK (1984) The plastic deformation of metals. Edward Arnold, London

M. R. Barnett, Nave MD Bettles CJ (2004) Mater Sci Eng A 386: 205

Huppmann Michael, Lentz Martin, Chedid Sarkis, Reimers Walter (2011) J Mater Sci 46:938. doi:10.1007/s10853-010-4838-0

Kuroda Mitsutoshi, Tvergaard Viggo (2007) Int J Plasticity 23:244

Ma Q, El Kadiri H, Oppedal AL, Baird JC, Li B, Horstemeyer MF, Vogel SC (2012) Int J Plasticity 29:60

Watanabe H, Mukai T, Ishikawa K, Higashi K (2002) Mater Trans 43:78

Bohlen J, Nürnberg MR, Senn JW, Letzig D, Agnew SR (2007) Acta Mater 55:2101

Mackenzie LWF, Pekguleryuz M (2008) Mater Sci Eng A 480:189

Agnew SR, Yoo MH, Tome CN (2001) Acta Mater 49:4277

Mukai T, Yamanoi M, Watanabe H, Higashi K (2001) Scripta Mater 45:89

Kuhlmann-Wilsdorf D (1997) Scripta Mater 36:173

Humphreys FJ, Hatherly M (2004) Recrystallization and related annealing phenomena. Pergamon Press, Oxford

Jin L, Lin DL, Mao DL, Zeng XQ, Chen B, Ding WJ (2006) Mater Sci Eng A 423:247

Roberts CS (1960) “The deformation of magnesium”. Magnesium and Its alloys. Wiley, New York

Wonsiewicz BC, Backofen EA (1967) Trans TMS AIME 239:1422

Taylor GI (1938) J Inst Met 62:307

Margolin H, Stanescu MS (1975) Acta Metall 23:1411

Bohlen J, Chmelík F, Kaiser F, Letzig D, Lukáč P, Kainer KU (2002) Kovevé Materiály 40(5):290

Chino Y, Mabuchi M (2009) Scripta Mater 60:447

Acknowledgements

This study was carried out as a collaborative research project supported by General Motors Global Research and Development Center (Warren, MI, USA). One of the authors, Li Jin, acknowledges the financial support of National Natural Sciences Foundation of China (Grant No. 50901044) and National Ministry of Science and Technology (2011BAE22B06).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jin, L., Dong, J., Luo, A.A. et al. Microstructure evolution of Mg-3%Al-1%Zn alloy tube during warm bending. J Mater Sci 47, 3801–3807 (2012). https://doi.org/10.1007/s10853-011-6234-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-6234-9