Abstract

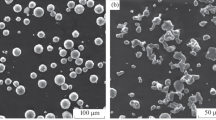

Densification kinetics study during microwave sintering of titanium nitride-based nanocomposite has been conducted. A series of TiN–SiC compositions with 1, 3, 5 wt% of silicon carbide were microwave sintered at relatively low sintering temperatures (900–1,300 °C) for 0–30 min. The SiC content influenced on heating uniformity and final density and grain-size achieved. Densification process during microwave sintering obeyed the mechanism of grain-boundary diffusion with activation energy of 235 kJ mol−1. Microwave sintering resulted in fine microstructure (~300 nm) and hence high values of micro hardness (~20 GPa).

Similar content being viewed by others

References

Pierson HO (1996) Handbook of refractory carbides and nitrides: properties characteristics processing and applications. Noyes Publications, New Jersey

Munsten A, Sagel K, Schlamp G (1954) Nature 174:1154

Kuzenkova MA, Kislyi PS (1971) Powder Metall Metal Ceram 10:125

Synielnikowa W, Niemyskia T, Panczyka J, Kierzek-Pecold E (1971) J Less-Common Met 23:1

Diserens M, Patscheider J, Levy F (1998) Surf Coat Technol 108–109:241

Hosokawa M, Nogi K, Naito M, Yokoyama T (eds) (2007) Nanoparticle Technology Handbook. Elsevier, Amsterdam

Troitskii VN, Rakhmatullina AZ, Berestenko VI, Gurov SV (1983) Powder Metall Metal Ceram 22:12

Ragulya AV (2008) Adv Appl Ceram 107:118

Themelin L, Desmaison-Brut M, Boncoeur M, Valin F, Microstructure, mechanical properties and oxidation behaviour of hot-isostatic-pressed titanium nitiride. L’Industrie Ceramique 828:426-433

Yamada T, Shimada M, Koizumi M (1980) Am Ceram Soc Bull 59:611

Groza JR, Curtis JD, Kramer M (2000) J Am Ceram Soc 83:1281

Wang L, Jiang W, Chen L, Yang M, Zhu H (2006) J Am Ceram Soc 89:2364

Angerer P, Yu LG, Khor KA, Korb G, Zalite I (2005) J Eur Ceram Soc 25:1919

Sherif El-Sekandarany M, Omori M, Konno TJ, Sumiyama K, Hirai T, Suzuki K (1998) Metall Mater Trans A 29A:1973

Agrawal DK (1998) Curr Opin Solid State Mater Sci 3:480

Binner J, Annapoorani K, Paul A, Santacruz I, Vaidhyanathan B (2008) J Eur Ceram Soc 28:973

Vaidhyanathan B, Agrawal DK, Roy R (2000) J Mater Res 15:974

Venkateswarlu K, Saurabh S, Rajinikanth V, Sahu RK, Ray AK (2010) J Mater Eng Perform 19(2):231

Matsumoto T, Makino Y, Miyake S (2001) Science 36:693

Pert E, Carmel Y, Birnboim A, Olorunyolemi T, Gershon D, Calame J, Lloyd IK, Wilson OC (2001) J Am Ceram Soc 84:1981

Niihara K, Morena R, Hasselman DPH (1982) J Mater Sci Lett 1:13

Tikkanen MH, Makipirtti SA (1965) Int J Powder Metll 1:15

Demirskyi D, Agrawal D, Ragulya A (2010) Mater Lett 64:1433

Fang Y, Agrawal DK, Roy R (2003) Microwave sintering of nano-phase MgO, TiO2, and Cu metal powders. In Proc. Sintering 2003, 15-17 September 2003, Penn State University, Pennsylvania: USA

Lynn Johnson D, Cutler IB (1963) J Am Ceram Soc 46:541

Lynn Johnson D, Cutler IB (1970) J Am Ceram Soc 53:136

Kuzenkova MA, Kislyi PS (1970) Powder Metall Ceram 9:379

Ragulya AV, Skorokhod VV (2007) Consolidated Nanostructured Materials. Naukova Dumka, Kiev

Nightingale SA (2001) Ionics 7:327

Birnboim A, Calame JP, Carmel Y (1999) J Appl Phys 85:478

Prochazka S, Coble RL (1970) Sintering 2:15

Moriyoshi Y, Komaysu W (1970) J Am Ceram Soc 53:671

Castro DT, Ying JY (1997) NanoStruct Mater 9:67

Andrievsky RA (1996) In: Chow GM, Gonsalves KE (eds) Nanotechnology: Molecularly Designed Materials. American Chemical Society, Washington DC, p 294

Andrievsky RA (1997) NanoStruct Mater 9:607

Acknowledgements

This study was supported by STCU #4259. The authors thank Dr. M. Gadzira (IPMS NASU) for providing nanocrystalline SiC powder used in the present investigation.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Demirskyi, D., Ragulya, A. Low-temperature microwave sintering of TiN–SiC nanocomposites. J Mater Sci 47, 3741–3745 (2012). https://doi.org/10.1007/s10853-011-6224-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-6224-y