Abstract

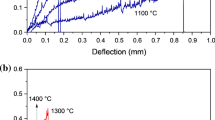

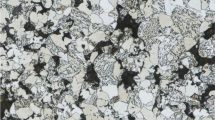

Following previous study on non-microcracked porous ceramics (SiC and alumina), we studied the micro and macrostrain response of honeycomb porous microcracked ceramics under applied uniaxial compressive stress. Cordierites of different porosities were compared. Both macroscopic and microscopic strains were measured, by extensometry and neutron diffraction, respectively. Lattice strains were determined using a single diffraction peak (steady-state neutron source) in both the axial and the transverse sample directions. Complementarily, we measured the macroscopic Young’s modulus of these materials as a function of temperature, at zero load, using high-temperature laser ultrasound spectroscopy. This allowed having a non-microcracked reference state for all the materials investigated. Confirming our previous study, we observed that macrostrain relaxation occurs at constant load, which is not observed in non-microcracked compounds, such as SiC. This relaxation effect increases as a function of porosity. Moreover, we generally observed a linear dependence of the diffraction modulus on porosity. However, for low and very high applied stress, the lattice strain behavior versus stress seems to be influenced by microcracking and shows considerable strain release, as already observed in other porous microcracked ceramics. We extended to microcracked porous ceramics (cordierite) the macro to microstrain and stress relations previously developed for non-microcracked ceramics, making use of the integrity factor (IF) model. Using the whole set of data available, the IF could also be calculated as a function of applied stress. It was confirmed that highly porous microcracked materials have great potential to become stiffer and more connected.

Similar content being viewed by others

References

Bruno G, Efremov AM, Webb JE (2010) Acta Mater 58:6649

Bruno G, Efremov AM, Wheaton BR, Bobrikov I, Simkin V, Misture S (2010) J Eur Ceram Soc 30:2555

Bruno G, Efremov AM, Wheaton BR, Webb JE, Brown D, Clausen B, Simkin V, Balagurov AM (2010) Acta Mater 58:1994

Pozdnyakova I, Bruno G, Efremov AM, Clausen B, Hughes DJ (2009) Adv Eng Mater 11:1023

Bruno G, Pozdnyakova I, Efremov AM, Levandovskyi AN, Clausen B, Hughes DJ (2010) Mater Sci Forum 652:191

Heap MJ, Vinciguerra S, Meredith PG (2009) Tectonophysics 471:153

Frishbutter A, Neov D, Scheffzük C, Vrana M, Walther K (2000) J Struct Geol 22:1587

Darling TW, TenCate JA, Brown DW, Clausen B, Vogel SC (2004) Geophys Res Lett 31:L16604

Nickerson ST, An CP, Boger T (2011) In: ASME McMATT conference, Chicago

Sato I, Ichikawa Y, Sakanoue J, Mizutani M, Adachi N, Ota T (2008) J Am Ceram Soc 91:607

Doncieux A, Stagnol D, Huger M, Chotard T, Gault C, Ota T, Hashimoto S (2008) J Mater Sci 43:4167. doi:10.1007/s10853-007-2414-z

Levandovskiy AN, Efremov AM, Bruno G (2012) Mater Sci Forum 706–709:1667

Levandovskiy AN, Efremov AM, Schermerhorn A (2010) In: Proceedings of the 3rd international conference on porous media and its applications in science and engineering ICPM3, Montecatini, June 2010

Bruno G, Efremov AM, Levandovskyi AN, Clausen B (2011) J Mater Sci 46:161. doi:10.1007/s10853-010-4899-0

Mori T, Tanaka K (1973) Acta Metall 21:571

Kachanov M, Tsukrov I, Shafiro B (1994) Appl Mech Rev 47:S151

McAdam GD (1951) J Iron Steel Inst 168:346

Gibson LJ, Ashby MF (1982) Proc R Soc Lond A382:43

Bruno G, Efremov AM, An CP, Nickerson ST (2011) In: Widjaja S, Singh D (eds) Advances in bioceramics and porous ceramics IV—ceramic engineering & science proceedings (CESP), vol 32, issue 6, p 137

Efremov AM (2006) Philos Mag 86:5431

Chen DKS (1990) In: ASME Winter Annual meeting, Dallas

Hauk V (1997) Structural and residual stress analysis by nondestructive methods: evaluation—application—assessment. Elsevier, Amsterdam

Noyan IC, Cohen JB (1987) Residual stress: measurement by diffraction and interpretation. Springer, New York

Bruno G, Fanara C, Hughes DJ, Ratel N (2006) Nucl Instrum Methods Phys Res B 246:425

Hughes DJ, Bruno G, Pirling T, Withers PJ (2006) Neutron News 17:28

Pirling T, Bruno G, Withers PJ (2006) Mater Sci Eng 437:139

ASTM C 623-92 (2000) Standard test method for Young’s modulus, shear modulus, and Poisson’s ratio for glass and glass ceramics by resonance

Scruby CB, Drain LE (1990) Laser ultrasonics: techniques and applications. Adam Hilger, Bristol

Efremov AM, Bruno G, Wheaton BR (2011) J Eur Ceram Soc 31:281

Bruno G, Vogel S (2008) J Am Ceram Soc 91:2646

Addiego WP, Melscoet-Chauvel IM (2007) High porosity cordierite ceramic article and method. US patent 2007/0142208 A1

Cleveland JJ, Bradt RC (1978) J Am Ceram Soc 61:478

Toohill K, Siegesmund S, Bass JD (1999) Phys Chem Miner 26:333

Lawn B (1993) Fracture of brittle solids. Solid state science series. Cambridge University Press, Cambridge

Gogotsi GA, Zavada VP, Kharatinov FYa (1984) Strength Mater 16:1651

Bruno G, Efremov AM, Brown DW (2010) Scr Mater 63:285

Backhaus-Ricoult M, Glose C, Tepesch P, Wheaton BR, Zimmermann J (2010) In: Narayan R, Colombo P (eds) Advances in bioceramics and porous ceramics III. Ceramic engineering and science proceedings, vol 31, issue 6, p 145

McKie D, McKie C (1990) Essentials of crystallography. Blackwell, Cambridge

Acknowledgments

Jean-Claude Collet-Fenetrier, John Allibon (ILL, Grenoble, F), Angela Graefe, Gregory Merkel, Ron Parysek (Corning Incorporated). Beamtime from the ILL, Grenoble, France, is greatly appreciated. Our Reviewer is gratefully acknowledged for the precious advice, and the stimulating exchange of ideas.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bruno, G., Efremov, A.M., An, C.P. et al. Connecting the macro and microstrain responses in technical porous ceramics. Part II: microcracking. J Mater Sci 47, 3674–3689 (2012). https://doi.org/10.1007/s10853-011-6216-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-6216-y