Abstract

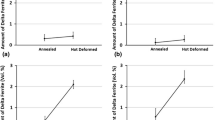

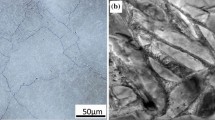

Two IN718 alloys with different initial δ phase contents have been used to study the microstructure evolution during the holding period after the hot deformation by the heat treatment at 950–1040 °C after deformation at temperature of 950 °C and strain rate of 0.005 s−1. The results indicate that the grain growth is restrained due to the pinning effect of δ phase. The activation energy of grain growth for the alloys with initial δ phase content of 0 and 8.14 wt% in the heat treatment after hot working were 273.8 and 882.8 kJ/mol, respectively. In addition, the dissolution of δ phase occurred during the heat treatment after the hot deformation, and the δ phase dissolved largely as the temperature is higher than 980 °C. Therefore, the heating and deformation temperature should be in the range of 950–980 °C for the Delta Process and multi-stage hot working processes.

Similar content being viewed by others

References

Ruiz C, Obabueki A, Gillespie K (1992) In: Evaluation of the microstructure and mechanical properties of Delta processed alloy 718. TMS (The Mineral, Metals & Material society), Warrendale

Dix AW, Hyzak JM, Singh RP (1992) In: Application of ultra fine grain alloy 718 forging billet. TMS (The Mineral, Metals & Material society), Warrendale

Bhowal PR, Schirra JJ (2001) In: Full scale Gatorizing™ Of fine grain Inconel718. TMS (The Mineral, Metals & Material society), Warrendale

Cai DY et al (2007) Mater Charact 58:220

Desvallées Y, Bouzidi M, Bois F, Beaude N (1994) In: Delta phase in Inconel718: mechanical properties and forging process requirements. TMS (The Mineral, Metals & Material society), Warrendale

Zhang Y, Huang XB, Wang Y, Yue W, Hu Z (1997) In: Delta phase and deformation fracture behaviour of Inconel 718 alloy. TMS (The Mineral, Metals & Material society), Warrendale

Yoshida H, Hatta T, Hironaka T, Isogawa S, Sekiguchi H (2007) In: Process modeling of IN718 for free forging. NUMIFORM, Porto

Yuan H, Liu WC (2005) Mater Sci Eng A 408:281

Wang Y et al (2009) J Alloy Compd 474:341

Yang XH et al (2007) Trans Shenyang Ligong Univ 26:64 (in Chinese)

Chen LQ et al (2009) Acta Metall Sinica 45:1242 (in Chinese)

Zhang JM et al (2000) J Mater Proc Tech 1010:25

Zhang HY et al (2010) Mater Charact 61:49

Hu JP (1999) Numerical simulation of Superalloy In718 and Gatorized Waspaloy during hot working. Ph. D Dissertation, Steel Research Institute (in Chinese)

Acknowledgements

This study has been supported by the National Natural Science Foundation of China with the Grant No: 50834008.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cheng, M., Zhang, H.Y. & Zhang, S.H. Microstructure evolution of delta-processed IN718 during holding period after hot deformation. J Mater Sci 47, 251–256 (2012). https://doi.org/10.1007/s10853-011-5792-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5792-1