Abstract

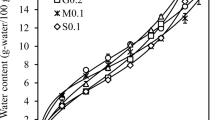

Sorption characteristics, thermo-mechanical and mechanical properties of bloodmeal-based thermoplastics have been investigated between water activities (a w) of 0.2 and 0.8, using water and tri-ethylene glycol (TEG) as plasticizers. Three different mass ratios of TEG to water were used, 1:1, 1:2 and 5:6 with a total plasticizer content of 60 parts per hundred parts bloodmeal. It was found that the equilibrium moisture content and mechanical properties were highly dependent on relative humidity suggesting that material properties may vary during use. The BET and Flory–Huggins equations gave the best fit for desorption and adsorption, respectively, but a significant difference was observed between adsorption and desorption behaviour below a water activity of 0.6, which was thought to be due to changes in intermolecular interactions. The monolayer adsorption capacity (0.05 g/g) was unaffected by the TEG content, using the BET sorption isotherm. The water activity required to form a monolayer (a wl) was also independent of the amount of TEG, but was different for adsorption and desorption (about 0.5 and 0.2, respectively). Increasing TEG did not have a strong influence on the equilibrium moisture content, especially at low water activity. Dynamic mechanical analysis revealed that the glass transition temperature decreased almost linearly with increasing water activity, ranging between 3 and 85 °C, however, above a water activity of 0.6 a second transition was observed, most likely due to phase separation. Depending of TEG content, tensile strength increased from about 10 to 15 MPa at a water activity of 0.4, where after a drastic decrease was observed. A similar trend was observed for elongation at break. At low water activity (below 0.4) elongation was less than 3%, increasing between 30 and 50% at higher water activities. It was concluded that 10–15 wt% represented a critical point above which mechanical properties becomes very sensitive to the relative humidity of the environment.

Similar content being viewed by others

References

Verbeek CJR, van den Berg LE (2009) Macromol Mater Eng 295(1):10

Verbeek C, van den Berg LE (2011) J Polym Environ 19:1. doi:10.1007/s10924-010-0232-x

Verbeek CJR, Viljoen C, Pickering KL, van den Berg LE (2009) NZ Patent NZ551531

Vanin FM, Sobral PJA, Menegalli FC, Carvalho RA, Habitante AMQB (2005) Food Hydrocolloid 19(5):899

Zhang Y, Han J (2008) J Food Sci 73(7):E313. doi:10.1111/j.1750-3841.2008.00867.x

Su J-F, Huang Z, Zhao Y-H, Yuan X-Y, Wang X-Y, Li M (2009) Ind Crops Prod 31(2):266

Hernandez-Izquierdo VM, Krochta JM (2008) J Food Sci 73(2):30

Maria Martelli S, Moore G, Silva Paes S, Gandolfo C, Laurindo JB (2006) Lebensm Wiss Technol 39(3):292

Cho SY, Rhee C (2002) Lebensm Wiss Technol 35(2):151

Verbeek CJR, van den Berg LE (2009) Recent Pat Mater Sci 2(3):171

Sharma S, Hodges JN, Luzinov I (2008) J Appl Polym Sci 110(1):459. doi:10.1002/app.28601

Swain SN, Rao KK, Nayak PL (2004) J Appl Polym Sci 93(6):2590

Zhang J, Mungara P, Jane J (2001) Polymer 42(6):2569

Pommet M, Redl A, Guilbert S, Morel M-H (2005) J Cereal Sci 42(1):81

Ortiz MER, San Martin-Martinez E, Padilla LPM (2008) Starch-Starke 60(10):577. doi:10.1002/star.200800212

Hochstetter A, Talja RA, Helén HJ, Hyvönen L, Jouppila K (2006) Lebensm Wiss Technol 39(8):893

Kristo E, Biliaderis CG (2006) Food Hydrocolloid 20(7):1057

Mali S, Sakanaka LS, Yamashita F, Grossmann MVE (2005) Carbohydr Polym 60(3):283

Perdomo J, Cova A, Sandoval AJ, García L, Laredo E, Müller AJ (2009) Carbohydr Polym 76(2):305

Fabra MJ, Talens P, Chiralt A (2009) Food Hydrocolloid 24(4):384

Cassini AS, Marczak LDF, Noreña CPZ (2006) J Food Eng 77(1):194

Brett B, Figueroa M, Sandoval A, Barreiro J, Müller A (2009) Food Biophys 4(3):151. doi:10.1007/s11483-009-9112-0

Jangchud A, Chinnan MS (1999) Lebensm Wiss Technol 32(2):89

Srinivasa PC, Ramesh MN, Kumar KR, Tharanathan RN (2003) Carbohydr Polym 53(4):431

Alix S, Philippe E, Bessadok A, Lebrun L, Morvan C, Marais S (2009) Bioresour Technol 100(20):4742

Sopade PA, Ajisegiri ESA, Chukwu O, Abass AB (2010) J Food Process Eng 33:385

Al-Muhtaseb AH, McMinn WAM, Magee TRA (2002) Food Bioprod Process 80(2):118

Kim SD, Chakravarti S, Tian J, Bell P (2010) Polymer 51(10):2199

Jonquières A, Perrin L, Arnold S, Lochon P (1998) J Membr Sci 150(1):125

Mo XQ, Sun XZ (2001) J Am Oil Chem Soc 78(8):867

Acknowledgements

The authors would like to thank Wallace Corporation for their support in supplying bloodmeal.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Verbeek, C.J.R., Koppel, N.J. Moisture sorption and plasticization of bloodmeal-based thermoplastics. J Mater Sci 47, 1187–1195 (2012). https://doi.org/10.1007/s10853-011-5770-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5770-7