Abstract

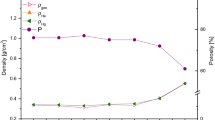

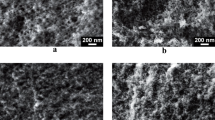

Xerogels were prepared by the sol–gel polymerization of resorcinol with formaldehyde at different conditions. The effects of different synthesis factors (namely, resorcinol-to-formaldehyde ratio, resorcinol-to-water ratio, resorcinol-to-catalyst ratio, and initial solution pH) on the surface areas, pore volumes, pore size distributions, and adsorption capacity of liquid nitrogen were studied. Factorial design was also used to investigate the relative significance of these factors on the resulting xerogels properties, and the possible interactions between them. The mean effects of the most significant factors and factor interactions on determining the pore structures and adsorption capacities were evaluated. The synthesized xerogels were characterized by Fourier transmission infrared spectroscopy, thermal gravimetric analysis, scanning electron microscopy, and surface area analyzer. The results showed that surface areas, pore size distributions, and nitrogen adsorption capacity are dependent completely on the recipes used to prepare the xerogels. Pore structure results put xerogel samples as candidates for adsorption technology, ultra-filtration, and nano-filtration fields based on pore sizes and pore volume scales.

Similar content being viewed by others

References

Mahata N, Pereira MFR, Suárez-García F, Martínez-Alonso A, Tascón JMD, Figueiredo JL (2008) J Colloid Interface Sci 324:150

Pekala RW (1989) J Mater Sci 24:3221. doi:https://doi.org/10.1007/BF01139044

Liu B, Creager S (2010) J Power Sources 195:1812

Wen Y, Shen Z (2001) Carbon 39:2369

Czakkel O, Marthi K, Geissler E, László K (2005) Microporous Mesoporous Mater 86:124

Zhao H, Zhu Y, Li W, Hu H (2008) New Carbon Mater 23:361

Lee YJ, Jung JC, Yi J, Baeck S, Yoon JR, Song IK (2010) Curr Appl Phys 10:682

Li J, Wang X, Wang Y, Huang Q, Dai C, Gamboa S, Sebastian PJ (2008) J Non-Cryst Solids 354:19

Zheivot VI, Molchanov VV, Zaikovskii VI, Krivoruchko VN, Zaitseva NA, Shchuchkin MN (2010) Microporous Mesoporous Mater 130:7

Wang Z, Zhang X, Liu X, Lv M, Yang K, Meng J (2011) Carbon 49:161

Job N, Panariello F, Marien J, Crine M, Pirard JP, Léonard A (2006) J Non-Cryst Solids 352:24

Albert DF, Andrew GRs, Mendenhall RS, Bruno JW (2001) J Non-Cryst Solids 296:1

Job N, Panariello F, Crine M, Pirard JP, Léonard A (2007) Colloids Surf A 293:224

Shady SA (2009) J Hazard Mater 167:947

Al-Muhtaseb SA, Ritter JA (2003) Adv Mater 15:101

Brinker CJ, Scherer GW (1990) Sol–gel science: the physics and chemistry of sol–gel processing. Academic Press, London

Lin C, Ritter JA (1997) Carbon 35:1271

Zanto EJ, Al-Muhtaseb SA, Ritter JA (2002) Ind Eng Chem Res 41:3151

Matos I, Fernandes S, Guerreiro L, Barata S, Ramos AM, Vital J, Fonseca IM (2006) Microporous Mesoporous Mater 92:38

Horikawa T, Ono Y, Hayashi J, Muroyama K (2004) Carbon 42:2683

Hwang SW, Hyun HS (2004) J Non-Cryst Solids 347:238

Van der Bruggen B, Everaert K, Wilms W, Vandecasteele C (2001) J Membr Sci 193:239

Zhu B, Clifford DA, Chellam S (2005) Water Res 39:3098

Bierman EL, Hayes TL, Hawkins JN, Ewing AM, Lindgren FT (1966) J Lipid Res 7:65

Lee WH, Park JS, Sok JH, Reucroft PJ (2005) Appl Surf Sci 246:77

González-González JF, Alexandre-Franco M, González-Garcìa CM, Encinar-Martìn JM, Bernalte-Garcìa A, Gómez-Serrano V (2009) Powder Technol 192:339

Acknowledgements

This publication was made possible by the support of an NPRP grant from the QNRF. The statements made herein are solely the responsibility of the authors.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Awadallah-F, A., Elkhatat, A.M. & Al-Muhtaseb, S.A. Impact of synthesis conditions on meso- and macropore structures of resorcinol–formaldehyde xerogels. J Mater Sci 46, 7760–7769 (2011). https://doi.org/10.1007/s10853-011-5755-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5755-6