Abstract

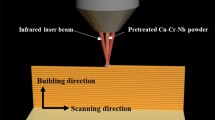

This article discusses the processing and properties of titanium nickelides locally sintered via Current-Activated Tip-based Sintering (CATS), a new localized sintering process. One of the advantages of CATS is the ability to apply orders of magnitude higher current densities than conventionally possible, which can promote rapid sintering and phase transformation rates. Mechanically alloyed equi-atomic Ni–Ti powder was for the first time tip sintered at varying current intensities and cumulative current exposure time. The effect of current-control processing conditions on the evolution of the locally sintered Ni–Ti microstructure and properties are discussed. The size of the locally sintered process zone was found to increase with cumulative current exposure time. The degree of sintering, phase transformations, and properties were found to depend on the current intensity, cumulative current exposure time and distance away from the tip/compact interface. Fully/near fully dense material was achieved rapidly at locations exposed to the highest current densities.

Similar content being viewed by others

References

Jin JL, Chi YH (2002) Mater Sci Forum 394–395:241

Zhang L, Xie C, Wu J (2006) Mater Sci Eng A438–440:905

Vermaut Ph, Ochin P, Dezellus A, Plaindoux Ph, Dalle F, Muguerra Ph, Portier R (2002) Mater Science Forum 394–395:483

Cheng X, Li Z, Xiang G (2007) J Mater Design 28(7):2218

Li Z, Xiang G, Cheng X (2006) J Mater Design 27(4):324

Hey JC, Jardine AP (1994) Mater Sci Eng A188(1–2):291

Takasaki A (1998) Phys Stat Sol A 169:183

Schuller E, Krone L, Bram M, Buchkremer HP, Stover D (2004) J Mat-iss.u Werkstofftech 35(5):326

Zhang N, Babayan Khosrovabadi P, Lindenhovius JH, Kolster BH (1992) J Mater Sci Eng A150(2):263

McNeese MD, Lagoudas DC, Pollock TC (2000) J Mater Sci Eng A 280(2):334

Fu YQ, Gu YW, Shearwood C, Luo JK, Flewitt AJ, Milne WI (2006) J Nanotechnology 17(21):5293

Morsi K, Patel VV, Moon KS, Garay JE (2008) J Mater Sci 43(12):4050. doi:https://doi.org/10.1007/s10853-007-2225-2

Munir ZA, Anselmi-Tamburini U (2006) J Mater Sci 41(3):763. doi:https://doi.org/10.1007/s10853-006-6555-2

Grasso S, Sakka Y, Maizza G (2009) Sci Technol Adv Mater 10:053001

Abadie J, Chaillet N, Lexcellent C, Bourjault A (1999) Proc SPIE Int Soc Opt Eng 3667:326

Yung KC, Zhu HH (2005) J Smart Mater Struct 14(2):337

Schuller E, Krone L, Bram M, Buchkremer HP, Stover D (2005) J Mater Sci 40(16):4231. doi:https://doi.org/10.1007/s10853-005-2819-5

Morsi K, Moon K, Kassegne S, Ugle R, Villar E (2009) Scripta Mater 60(9):745

Morsi K, Moon KS, Current activated tip-based sintering, PCT/US2009/35616 (pending)

Locci AM, Orrùb R, Cao G, Munir ZA (2003) Intermetallics 11:555

Koch CC (1989) Ann Rev Mater Sci 19:121

Suryanarayana C (2001) Prog Mater Sci 46:1

Chen W, Anselmi-Tamburini U, Garay JE, Groza JR, Munir ZA (2005) Mater Sci Eng A394:1332

Zoz H, Ernst D, Ahn IS, Kwon WH (1997) In: Ward-Close CM, Froes FH, Cho SS, Chellman DJ (eds) Synthesis/processing of lightweight metallic materials. TMS, Warrendale

Otsuka K, Wayman CM (1988) Shape memory materials. Cambridge University Press, Cambridge

Bertheville B, Bidaux J-E (2005) Scripta Mater 52:507

Shearwood C, Fu YQ, Yu L, Khor KA (2005) Scripta Mater 52:455

Schuller E, Bram M, Buchkremer HP, Stover D (2004) Mater Sci Eng A378:165

Bram M, Ahmad-Khanlou A, Heckmann A, Fuchs B, Buchkremer HP, Stover D (2002) Mater Sci Eng A337:254

Krone L, Schuller E, Bram M, Hamed O, Buschkremer H-P, Stover D (2004) Mater Sci Eng A378:185

Ye LL, Liu ZG, Raviprasad K, Quan MX, Umemoto M, Hu ZQ (1998) Mater Sci Eng A241:290

Luo H, Shan F, Huo Y, Wang Y (1999) Thin Solid Films 339:305

Frenzel J, George EP, Dlouhy A, Somsen Ch, Wagner MF-X, Eggeler G (2010) Acta Mater 58:3444

Hiraga H, Inoue T, Shimura H, Matsunawa A (1999) Wear 231:272

Tan L, Crone WC (2002) Acta Mater 50:4449

Conrad H (2002) Mater Sci Eng A287:227

Garay JE, Anselmi-Tamburini U, Munir ZA (2003) Acta Mater 51(15):4487

Acknowledgements

The authors express their thanks to Dr. Steve Barlow and Ms. Joan Kimbrough for their help with electron microscopy and XRD. Thanks are also to Mr. Greg Morris and Mr. Mike Lester for general technical support. The authors also wish to thank The National Science Foundation (CMMI division: grant no. 0826532) for their support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Patel, M., Moon, K.S., Kassegne, S.K. et al. Effects of current intensity and cumulative exposure time on the localized current-activated sintering of titanium nickelides. J Mater Sci 46, 6690–6699 (2011). https://doi.org/10.1007/s10853-011-5622-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5622-5