Abstract

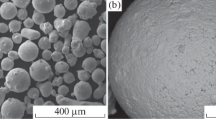

Laser consolidation (LC) developed by National Research Council’s Industrial Materials Institute (NRC-IMI-London) since mid-1990s, is a laser cladding based rapid manufacturing and material additive process that could fabricate a “net-shape” functional metallic shape through a “layer-upon-layer” deposition directly from a computer aided design model without using molds or dies. In order to evaluate the LC processability of different materials, some representative nickel-based superalloys (IN-625, IN-718, IN-738, and Waspaloy), stainless steels (austenitic SS316L and martensitic SS420), and lightweight alloys (Ti–6Al–4V titanium alloy and Al-4047 aluminum alloy) have been investigated. Like other laser cladding based processes, due to process-induced rapid directional solidification, the LC alloys have demonstrated certain unique morphological characteristics. Moreover, the “as-consolidated” LC alloys, in nature, are in the “as-quenched” state, and some precipitation processes from their matrices, which are sometimes critical to the development of mechanical performance of the materials, could be effectively suppressed or retarded. Post-heat treatments, therefore, could necessarily facilitate the process of achieving their required operational microstructures. In this article, a comprehensive investigation was performed including metallurgical soundness and process-induced morphological characteristics of the LC materials, and microstructure development brought by post-LC heat treatments using optical microscope, scanning electron microscope, and X-ray diffraction. The implications on the mechanical performance of the LC materials were discussed as well in order to provide essential information for potential industrial applications of the LC materials.

Similar content being viewed by others

References

Smugeresky JE, Keicher DM, Romero JA, Griffith ML, Harwell LD (1997) DOC Report #: SAND-97-8652C, USA

Schlienger E, Dimos D, Griffith M, Michael J, Oliver M (1998) DOC Report #: SAND-98-0664C, USA

Lewis GK, Nemec RB, Milewski JO, Thoma DJ, Barbe MR, Cremers DA (1994) In: ICALEO’94. LIA, Orlando, p 17

Mazumder J, Choi J, Nagarathnam K, Koch J, Hetzner D (1997) JOM 49(5):55

Mazumder J (2000) JOM 52:28

Abbott DH, Arcella FG (1998) Adv Mater Process 153(5):29

Murphy ML, Lee C, Steen WM (1993) In: ICALEO’93. LIA, Orlando, p 882

Toyserkani E, Khajepour A, Corbin S (2005) Laser cladding. CRC Press, Boca Raton, p 2

McLean MA, Shannon GJ, Steen WM (1997) SPIE 3092:753

Hill R, Lewis GK (1998) In: Aerospace manufacturing technology conference and exposition: Session: Emerging Processes/Affordability—Part B. SAE, Long Beach

Mazumder J, Dutta D, Kikuchi N, Ghosh S (2000) Opt Lasers Eng 34:397

Choi J, Hua Y (2004) J Laser Appl 16(4):245

Mazumder J (2004) US20040020625

Nowotny S, Scharek S, Beyer E, Richter KH (2007) J Therm Spray Technol 16(3):344

Huan Q, Prabhjot S, Naim AM (2008) CA2618926

Toyserkani E, Khajepour A, Corbin S (2005) Laser cladding. CRC Press, Boca Raton, p 8

Costa L, Vilar R (2009) Rapid Prototyp J 15(4):264

Xue L, Islam M (1998) In: ICALEO’98. LIA, Orlando, p Section E:15

Xue L (2006) In: Session: Additive manufacturing in aerospace manufacturing and automated fastening conference and exhibition. Toulouse

Xue L, Purcell CJ, Theriault A, Islam M (2001) In: ICALEO’01. LIA, Jacksonville, p 702

Xue L, Chen J, Wang SH, Li Y (2009) In: ICALEO’09. LIA, Orlando, (Oral presentation only)

Blackwell PL (2005) J Mater Process Technol 170:240

Pinkerton AJ, Karadge M, Syed W, Li L (2006) J Laser Appl 18(3):216

Wang L, Felicelli S, Pratt P (2008) Mater Sci Eng A 496:234

Wu X, Liang J, Mei J, Mitchell C, Goodwin PS, Voice W (2004) Mater Des 25:137

Kummailil J, Sammarco C, Skinner D, Brown CA, Rong K (2005) J Manuf Process 7(1):42

Choi J, Chang Y (2005) Int J Machine Tools Manuf 45:597

Chen J, Xue L (2010) Mater Sci Eng A 527:7318

Donachie MJ, Donachie SJ (2002) Superalloys: a technical guide, 2nd edn. ASM International, Materials Park, p 11

International ASM (1991) ASM handbook, heat treating, vol 4. ASM International, Materials Park, p 770

Donachie MJ (2000) Titanium: a technical guide. ASM International, Materials Park, p 13

Aluminium-Verlag Marketing and Kommunikation GmbH (1999) Aluminium handbook: fundamentals and materials, vol 1. Aluminium-Zentrale e.V, Düsseldorf, p 86

Donachie MJ, Donachie SJ (2002) Superalloys: a technical guide, 2nd edn. ASM International, Materials Park, p 140

Kahlen FJ, Kar A (2001) J Laser Appl 13(2):60

Pryds NH (1997) Rapid solidification of the 12%Cr steel, Risø-R-992 (EN). Risø National Laboratory, Roskile, p 39

Marsden CF, West DRF, Steen WM (1987) In: Proceedings of LAMP’ 87. Osaka, Japan, p 401

Pryds NH (1997) Rapid solidification of the 12%Cr steel, Risø-R-992 (EN). Risø National Laboratory, Roskile, p 29

Lee JH, Kim HC, Jo CY, Kim SK, Shin JH, Liu S, Trivedi R (2005) Mater Sci Eng A 413–414:306

Antonsson T, Fredriksson H (2005) Metall Mater Trans B 36B:85

Vilar R, Conde O, Colin D (1990) In: Sudarshan TS, Bhat DG (eds) Surface modification technologies III. Miner Metals Mater Soc, Warrendale, p 343

Colaco R, Vilar R (1997) Scr Mater 36(2):199

Colaco R, Vilar R (1998) In: Sudarshan TS, Jeandin M, Khor KA (eds) Surface modification technologies XI. The Institute of Materials, London, p 600

Lin X, Yue TM (2005) Mater Sci Eng A 402:294

Semiatin SL, Kobryn PA (2001) JOM 53:40

Bontha S, Klingbeil NW, Kobryn PA, Fraser HL (2006) J Mater Process Technol 178:135

Lavernia EJ, Srivatsan TS (2010) J Mater Sci 45:287. doi:https://doi.org/10.1007/s10853-009-3995-5

Xue L, Chen J, Islam M, Pritchard J, Manente D, Rush S (2000) In: ICALEO’ 00. LIA, Dearborn, p D.30

ASM International (1980) Metals Handbook, vol 3 (9th edn), properties and selection: stainless steels, tool materials and special-purpose metals. ASM International, Materials Park, p 27

Acknowledgements

The authors would like to acknowledge A. Theriault, A. Gillett, N. Santos, G. Wabersich, B. Gibson, A. Chen, and M. Meinert, NRC-IMI (London, ON), for their important contributions to the preparation of the LC specimens for metallurgical characterization and mechanical testing, and the authors are grateful to Dr. Jiaren (Jimmy) Jiang, NRC Institute for Fuel Cell Innovation (Vancouver, BC), for some useful discussion on rapid directional solidification of metals during the preparation of the manuscript as well.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, J., Xue, L. & Wang, SH. Experimental studies on process-induced morphological characteristics of macro- and microstructures in laser consolidated alloys. J Mater Sci 46, 5859–5875 (2011). https://doi.org/10.1007/s10853-011-5543-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-011-5543-3