Abstract

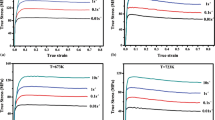

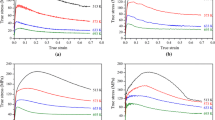

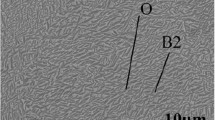

The hot deformation behavior of Al 2024 was studied by isothermal hot compression tests in the temperature range of 250–500 °C and strain rate range of 10−3 to 102 s−1 in a computer-controlled 50 kN servo-hydraulic universal testing machine (UTM). The results show that the flow stress of Al 2024 alloy increases with strain rate and decreases after a peak value, indicating dynamic recovery and recrystallization. The processing map exhibits two domains of optimum efficiency for hot deformation at different strains, including the low strain rate domain at 500 °C and between 10−2 and 10−1 s−1 and the high strain rate domain in 250 and 300 °C in the strain rate range of 101 to 102 s−1. An attempt has been made in this article to generate a new hybrid 4D process map which illustrates contours of power dissipation and instability in the 3D space of strain rate, temperature, and strain.

Similar content being viewed by others

References

Malas JC, Venugopal S, Seshacharyulu T (2004) Mater Sci Eng A 368:41

Babu NS, Tiwari SB, Nageswararao B (2005) Mater Sci Technol 21(8):976

Sellars CM, Zhu Q (2000) Mater Sci Eng A 280:1

Maheshwari AK, Pathak KK, Ramakrishnan N, Narayan SP (2009) J Mater Sci 45(4):859. doi: 10.1007/s10853-009-4010-x

Prasad YVRK, Sasidhara S (1997) Hot working guide: A compendium of processing maps. ASM International, Metals Park

Sivakesavam O, Rao IS, Prasad YVRK (1993) Mater Sci Technol 9:805

Prasad YVRK, Giegel HL, Doraivelu SM, Malas JC, Morgan JT, Lark KA, Barker DR (1984) Metall Mater Trans A 15:1883

Srinivasan N, Prasad YVRK, Rama Rao P (2008) Mater Sci Eng A 476:146

Siva Prasad PV, Venu Gopal S (2003) J Mater Eng Perform 12(6):656

Ravichandran N (2003) J Mater Eng Perform 12(6):653

Campbell FC (2008) Elements of Metallurgy and Engineering Alloys. ASM International, Metals Park

Narayana murty SVS, Nageswara rao B (1998) J Mater Sci Lett 17(14):1203

Narayana murty SVS, Nageswara rao B (1999) J Mater Sci Lett 18(21):1757

Sivakesavam O, Prasad YVRK (2003) Mater Sci Eng A 362:118

Jonas JJ, Sellars CM, Tegart WJMcG (1969) Met Rev 14:1

Sellars CM, Tegart WJ, Mc G (1972) Int Metall Rev 17(158):1

Glover G, Sellars CM (1973) Metall Mater Trans B 4(3):765

McQueen HJ, Ryan ND (2002) Mater Sci Eng A 322:43

Sellars CM (1978) Philos Trans R Soc 288:147

Liu J, Cui Z, Li C (2008) J Mater Proc Technol 205(1–3):497

Acknowledgements

The authors are thankful to the Director, AMPRI, Bhopal for granting the permission to publish this article, Prof. V. Rao for helping in revising the technical content of the article. The authors are also thankful to the reviewers for their invaluable comments and suggestions, without which the article may not be in the present form.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bhimavarapu, S.B., Maheshwari, A.K., Bhargava, D. et al. Compressive deformation behavior of Al 2024 alloy using 2D and 4D processing maps. J Mater Sci 46, 3191–3199 (2011). https://doi.org/10.1007/s10853-010-5203-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-5203-z