Abstract

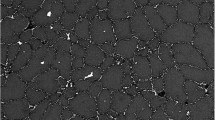

Deformation behavior of an Al–Cu–Mg–Mn–Zr alloy during hot compression was characterized in present work by high-temperature testing and transmission electron microscope (TEM) studies. The true stress–true strain curves exhibited a peak stress at a critical stain. The peak stress decreased with increasing deformation temperature and decreasing strain rate, which can be described by Zener–Hollomon (Z) parameter in hyperbolic sine function with the deformation activation energy 277.8 kJ/mol. The processing map revealed the existence of an optimum hot-working regime between 390 and 420 °C, under strain rates ranging from 0.1 to 1 s−1. The main softening mechanism of the alloy was dynamic recovery at high lnZ value; continuous dynamic recrystallization (DRX) occurred as deformed at low lnZ value. The dynamic precipitation of Al3Zr and Al20Cu2Mn3 dispersoids during hot deformation restrained DRX and increased the hot deformation activation energy of the alloy.

Similar content being viewed by others

References

Williams JC, Starke EA Jr (2003) Acta Mater 51:5775

Okayasu M, Sato K, Mizuno M (2008) J Mater Sci 43:2792. doi:10.1007/s10853-008-2544-y

Parel TS, Wang SC, Statrink MJ (2010) Mater Des 31:S2

Gao N, Starink MJ, Kamp N, Sinclair I (2007) J Mater Sci 42:4398. doi:10.1007/s10853-006-0659-6

Cavaliere P (2002) J Light Met 2:247

Liu XY, Pan QL, He YB, Li WB, Liang WJ, Yin ZM (2009) Mater Sci Eng A 500:150

Li HZ, Li Z, Song M, Liang XP, Guo FF (2010) Mater Des 30:2171

Banerjee S, Robi PS, Srinivasan A, Kumar LP (2010) Mater Sci Eng A 527:2498

Ebrahimi GR, Zarei-Hanzaki A, Haghshenas M, Arabshahi H (2008) J Mater Proc Technol 206:25

Huang XD, Zhang H, Han Y, Wu WX, Chen JH (2010) Mater Sci Eng A 527:485

Zhang H, Li LX, Yuan D, Peng DS (2007) Mater Charact 58:168

Meng G, Li BL, Li HM, Huang H, Nie ZR (2009) Mater Sci Eng A 516:131

Jin NP, Zhang H, Han Y, Wu WX, Chen JH (2009) Mater Charact 60:530

Castillo LD, Lavernia EJ (2000) Metall Mater Trans A 31:2287

Robson JD, Prangnell PB (2001) Acta Mater 49:599

Wang SC, Starink MJ (2005) Int Mater Rev 50:193

Cabibbo M, Evangelista E, Spigarell S (2004) Metall Mater Trans A 35:293

Chiba A, Lee SH, Matsumoto H, Nakamura M (2009) Mater Sci Eng A 513–514:286

Jagan RG, Srinivasana N, Gokhalea AA, Kashyapb BP (2009) J Mater Proc Technol 209:5964

Cai DY, Xiong LY, Liu WC, Sun GD, Yao M (2009) Mater Des 30:921

Anbuselvan S, Ramanathan S (2010) Mater Des 31:2319

Łyszkowski R, Bystrzycki J (2006) Intermetallics 14:1231

McQueen HJ, Ryan ND (2002) Mater Sci Eng A 322:43

Zong YY, Shan DB, Xu M, Lu Y (2009) J Mater Proc Technol 209:1988

El-Danaf EA, AlMajid AA, Soliman MS (2008) J Mater Sci 43:6324. doi:10.1007/s10853-008-2895-4

McQueen HJ, Imbert CAC (2004) J Alloys Compd 378:35

Spigarelli S, Cabibbo M, Evangelista E (2003) J Mater Sci 38:81. doi:10.1023/A:1021161715742

Prasad YVRK, Rao KP (2005) Mater Sci Eng A 391:141

Cui C, Schulz A, Epp J, Zoch HW (2010) J Mater Sci 45:2798. doi:10.1007/s10853-010-4269-y

Prasad SK, Gokhale AA, Mukhopadhyay AK, Banejee D, Goel DB (1999) Acta Mater 47:2581

Mohamed FA, Langdon TG (1974) Met Trans 5:2339

Acknowledgements

The authors would like to acknowledge the financial support of National Key Fundamental Research Project of China (Grant No. 2005CB623705-04) and Natural Science Foundation of Hunan Province (Grant No. 08JJ3101).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Y., Liu, Z., Lin, L. et al. Deformation behavior of an Al–Cu–Mg–Mn–Zr alloy during hot compression. J Mater Sci 46, 3708–3715 (2011). https://doi.org/10.1007/s10853-010-5143-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-5143-7