Abstract

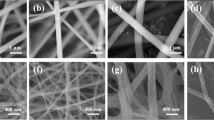

Magnetically separable TiO2-coated SrFe12O19 electrospun nanofibers were obtained successfully by means of sol–gel, electrospinning, and coating technology, followed by heat treatment at 550–650 °C for 3 h. The average diameter of the electrospun fibers was 500–600 nm. The fibers were characterized by X-ray diffraction (XRD), scanning electron microscopy (SEM), transmission electron microscope (TEM), and vibrating sample magnetometer (VSM). The optimized calcining temperature was determined by XRD and the analysis of decolorizing efficiency of methylene blue (MB) under UV–vis irradiation. The photocatalytic activity of the TiO2-coated SrFe12O19 fibers was investigated using ultraviolet–visible absorbance by following the photooxidative decomposition of a model pollutant dye solution, MB in a photochemical reactor. In contrast to pure TiO2 fibers, the TiO2-coated SrFe12O19 fibers have higher absorption in 250–750 nm wavelength regions. The presence of SrFe12O19 not only broadened the response region of visible-light, but also enhanced the absorbance for UV light. The decolorizing efficiency of MB under UV–vis irradiation was up to 98.19%, which was a little higher than that of Degussa P25 (97.68%). Furthermore, these fibers could be recollected easily with a magnet in a photocatalytic process and had effectively avoided secondary pollution of treated water.

Similar content being viewed by others

References

Alves AK, Berutti FA, Clemens FJ, Graule T, Bergmann CP (2009) Mater Res Bull 44:312

Zhang BP, Zhang JL, Chen F (2008) Res Chem Intermed 34:375

Kim S, Lim SK (2008) Appl Catal B Environ 84:16

Ao YH, Xu JJ, Fu DG, Yuan CW (2009) J Alloys Compd 471:33

Kanjwal MA, Barakat NAM, Sheikh FA et al (2010) J Mater Sci 45:1272. doi:10.1007/s10853-009-4078-3

Hu GJ, Meng XF, Feng XY et al (2007) J Mater Sci 42:7162. doi:10.1007/s10853-007-1609-7

Santala E, Kemell M, Leskelä M, Ritala M (2009) Nanotechnology 20:035602

Dong SH, Xu KJ, Tian GS (2009) J Mater Sci 44:2548. doi:10.1007/s10853-009-3332-z

Formo E, Lee E, Campbell D, Xia YN (2008) Nano Lett 8:668

Li D, Xia Y (2004) Adv Mater 16:1151

Reneker DH, Chun I (1996) Nanotechnology 7:216

Frenot A, Chronakis IS (2003) Curr Opin Colloid Interface Sci 8:64

Huang ZM, Zhang YZ, Kotaki M, Ramakrishna S (2003) Compos Sci Technol 63:2223

Subbiah T, Bhat GS, Tock RW, Pararneswaran S, Ramkumar SS (2005) J Appl Polym Sci 96:557

Li D, McCann JT, Xia Y (2006) J Am Ceram Soc 89:1861

Guo YZ, Li CJ, Wang JN (2009) Chin J Inorg Chem 25:1018

Li CJ, Wang JN (2010) Mater Lett 64:586

Nga TTV, Hien TD, Duong NP, Hoang TD (2008) J Korean Phys Soc 52:1474

Nga TTV, Duong NP, Hien TD (2009) J Alloys Compd 475:55

Chu JY, Yu Q, Wu CD, Cao CL, Li N (2008) J Inorg Mater 23:652

Zuo XW, Fei P, Hu CL, Su BT, Lei ZQ (2009) Chin J Inorg Chem 25:1233

Wan MX, Li WG (1997) J Polym Sci Polym Chem 35:2129

Chiou CH, Wu CY, Juang RS (2008) Chem Eng J 139:322

Ao YH, Xu JJ, Zhang SH, Fu DG (2009) J Phys Chem Solids 70:1042

Lee JA, Krogman KC, Ma M, Hill RM, Hammond PT, Rutledge GC (2009) Adv Mater 21:1252

Kim YB, Cho D, Park WH (2010) J Appl Polym Sci 116:449

Zhan S, Chen D, Jiao X, Song Y (2007) Chem Commun 20:2043

Zhang T, Ge L, Wang X, Gu Z (2008) Polymer 49:2898

Rizzo L, Koch J, Belgiorno V, Anderson MA (2007) Desalination 211:1

Acknowledgement

This study was partly supported by the Natural Science Foundation of China (Grant no. 51073005), the Beijing Natural Science Foundation (Grant no. KZ201010012012), PHR (IHLB), the 863 Project (Grant no. 2007AA021906), and the 973 Project (Grant no. 2010CB933501).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, CJ., Wang, JN., Li, XY. et al. Functionalization of electrospun magnetically separable TiO2-coated SrFe12O19 nanofibers: strongly effective photocatalyst and magnetic separation. J Mater Sci 46, 2058–2063 (2011). https://doi.org/10.1007/s10853-010-5038-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-5038-7