Abstract

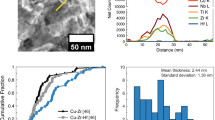

This study presents evidence that the microstructural stability of fine-grained and nanocrystalline Cu is improved by alloying with Sb. Experimentally, Cu100−x Sb x alloys are cast in three compositions (Cu-0.0, 0.2, and 0.5 at.%Sb) and extruded into fine-grained form (with average grain diameter of 350 nm) by equal channel angular extrusion. Alloying the Cu specimens with Sb causes an increase in the temperature associated with microstructural evolution to 400 °C, compared to 250 °C for pure Cu. This is verified by measurements of microhardness, ultimate tensile strength, and grain size using transmission electron microscopy. Complementary molecular dynamics (MD) simulations are performed on nanocrystalline Cu–Sb alloy models (with average grain diameter of 10 nm). MD simulations show fundamentally that Sb atoms placed at random sites along the grain boundaries can stabilize the nanocrystalline Cu microstructure during an accelerated annealing process.

Similar content being viewed by others

References

Dao M, Lu L, Asaro RJ, De Hosson JTM, Ma E (2007) Acta Mater 55:4041

Meyers MA, Mishra A, Benson DJ (2006) Prog Mater Sci 51:427

Weertman JR (1993) Hall-petch strengthening in nanocrystalline metals. Mater Sci Eng A 166:161

Gleiter H (2000) Acta Mater 48:1

Ganapathi SK, Owen DM, Chokshi AH (1991) Scripta Metall Mater 25:2699

Gunther B, Kumpmann A, Kunze HD (1992) Scripta Metall Mater 27:833

Gertsman VY, Birringer R (1994) Scripta Metall Mater 30:577

Rajgarhia RK, Koh SW, Spearot D, Saxena A (2008) Mol Simul 34:35

Moelle CH, Fecht HJ (1995) Nanostruct Mater 6:421

Zhang K, Weertman JR, Eastman JA (2005) Appl Phys Lett 87:61921

Hibbard GD, Radmilovic V, Aust KT, Erb U (2008) Mater Sci Eng A 494:232

Ames M, Markmann J, Karos R, Michels A, Tschope A, Birringer R (2008) Acta Mater 56:4255

Sansoz F, Dupont V (2006) Appl Phys Lett 89:111901

Farkas D, Froseth A, Van Swygenhoven H (2006) Scripta Mater 55:695

Natter H, Schmelzer M, Loffler MS, Krill CE, Fitch A, Hempelmann R (2000) J Phys Chem B 104:2467

Li JCM (2006) Phys Rev Lett 96:215506

Weissmuller J (1994) J Mater Res 9:4

Kirchheim R (2002) Acta Mater 50:413

Millett PC, Selvam RP, Saxena A (2007) Acta Mater 55:2329

Millett PC, Selvam RP, Saxena A (2006) Acta Mater 54:297

Michels A, Krill CE, Ehrhardt H, Birringer R, Wu DT (1999) Acta Mater 47:2143

Randle V (1996) The role of the coincidence site lattice in grain boundary engineering. Institute of Materials, London

Chen Z, Liu F, Wang HF, Yang W, Yang GC, Zhou YH (2009) Acta Mater 57:1466

Li J, Wang J, Yang G (2009) Scripta Mater 60:945

Detor AJ, Schuh CA (2007) Acta Mater 55:4221

Botcharova E, Freudenberger J, Schultz L (2006) Acta Mater 54:3333

Wang YM, Jankowski AF, Hamza AV (2007) Scripta Mater 57:301

Suryanarayanan R, Frey CA, Sastry SML, Waller BE, Buhro WE (1999) Mater Sci Eng A 264:210

Mehta SC, Smith DA, Erb U (1995) Mater Sci Eng A A204:227

Liu F, Chen Z, Yang W, Yang CL, Wang HF, Yang GC (2007) Mater Sci Eng A 457:13

Darling KA, Chan RN, Wong PZ, Semones JE, Scattergood RO, Koch CC (2008) Scripta Mater 59:530

Krill CE, Klein R, Janes S, Birringer R (1995) Mater Sci Forum 179–181:443

Liu KW, Mucklich F (2001) Acta Mater 49:395

Weissmuller J, Krauss W, Haubold T, Birringer R, Gleiter H (1992) Nanostruct Mater 1:439

Valiev RZ, Islamgaliev RK, Alexandrov IV (2000) Prog Mater Sci 45:103

Dalla Torre FH, Gazder AA, Pereloma EV, Davies CHJ (2007) J Mater Sci 42:1622. doi:10.1007/s10853-006-1283-1

Mishin Y, Mehl MJ, Papaconstantopoulos DA, Voter AF, Kress JD (2001) Phys Rev B 63:224101

Zimmerman JA, Gao H, Abraham FF (2000) Model Simul Mater Sci Eng 8:103

Van Swygenhoven H, Derlet PM, Froseth AG (2004) Nat Mater 3:399

Millett PC, Selvam RP, Saxena A (2006) Mater Sci Eng A 431:92

Subramanian PR, Chakrabarti DJ, Laughlin DE, Massalshi TB (1993) Phase diagrams of binary copper alloys. ASM International, Materials Park

Staley JT Jr, Saxena A (1990) Acta Metall 38:897

Schaffer J, Saxena A, Sanders T, Antolovich S, Warner S (2000) Science and design of engineering materials, 2nd edn. McGraw-Hill Science, New York

Haas V, Gleiter H, Birringer R (1993) Scripta Metall Mater 28:721

Koch CC (1993) Nanostruct Mater 2:109

Beyerlein IJ, Toth LS, Tome CN, Suwas S (2007) Philos Mag 87:885

Xue Q, Beyerlein IJ, Alexander DJ, Gray Iii GT (2007) Acta Mater 55:655

Aggarwal AO, Markondeya Raj P, Pratap RJ, Saxena A, Tummala RR (2002) Design and fabrication of high aspect ratio fine pitch interconnects for wafer level packaging. In: Proceedings 4th electronics packaging technology conference (EPTC 2002)

Bansal S, Saxena A, Tummala RR (2004) Nanocrystalline copper and nickel as ultra high-density chip-to-package interconnections. In: Proceedings—electronic components and technology conference

Randle V, Engler O (2000) Introduction to textru analysis: macrotexture, microtexture and orientation mapping. Gordon and Breach Science Publishers, London

Rajgarhia R, Spearot DE, Saxena A (2010) J Mater Res 25:411

Plimpton SJ, Large-scale atomic/molecular massively parallel simulator, http://lammps.sandia.gov

Rajgarhia R, Spearot DE, Saxena A (2008) Comput Mater Sci 44:1258

Spearot DE, Jacob KI, McDowell DL (2005) Acta Mater 53:3579

Spearot DE, McDowell DL (2009) J Eng Mater Technol 131:041204

Rajgarhia RK, Spearot DE, Saxena A (2009) Model Simul Mater Sci Eng 17:055001

Mackenzie JK (1958) Biometrika 45:229

Froseth AG, Van Swygenhoven H, Derlet PM (2005) Acta Mater 53:4847

Kelchner CL, Plimpton SJ, Hamilton JC (1998) Phys Rev B 58:11085

Hoover WG (1985) Phys Rev A 31:1695

Melchionna S, Ciccotti G, Holian BL (1993) Mol Phys 78:533

Acknowledgements

Funding for this work was provided by the Irma and Raymond Giffels’ Endowed Chair in Engineering at the University of Arkansas. DES appreciates additional support from Oak Ridge Associated Universities via the Ralph E. Powe Junior Faculty Enhancement Award. Molecular dynamics simulations were performed on “Star of Arkansas”, funding for which was provided in part by the National Science Foundation under Grant MRI #072265. Support from the Department of Energy for conducting the TEM, OIM and Auger Spectroscopy analysis at the SHaRE User Facility at the Oak Ridge National Laboratory is acknowledged. TEM, OIM and Auger Electron Spectroscopy analysis were performed at the Oak Ridge National Laboratory SHaRE User Facility that is sponsored by the Division of Scientific User Facilities, Office of Basic Energy Sciences, U.S. Department of Energy. Support from the Texas Engineering Experiment Station for ECAE processing is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajgarhia, R.K., Saxena, A., Spearot, D.E. et al. Microstructural stability of copper with antimony dopants at grain boundaries: experiments and molecular dynamics simulations. J Mater Sci 45, 6707–6718 (2010). https://doi.org/10.1007/s10853-010-4764-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4764-1