Abstract

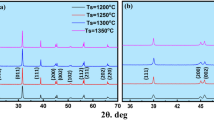

Nanostructured (~200 nm grain size) titanium dioxide (TiO2) ceramics were densified at temperature as low as 800 °C by pressureless sintering in a pure oxygen atmosphere. Phase transition and microstructural development of sintered samples were studied by X-ray diffraction (XRD) and scanning electron microscopy (SEM). Dielectric properties including d.c. conductivity, dielectric constant, loss tangent, and dielectric breakdown strength (BDS) were determined for samples sintered at various temperatures. The influence of sintering temperature on the microstructural development, defect chemistry, and dielectric properties of TiO2 is discussed. Nanostructured TiO2 ceramics with high sintering density (>98%) lead to improved dielectric properties; high BDS (~1800 kV/cm), low electrical conductivity (~5 × 10−15 S/cm), high dielectric constant (~130), and low loss tangent (~0.09% at 1 kHz), which is promising for application in high energy density capacitors.

Similar content being viewed by others

References

Yeh YC, Tseng TT, Chang DA (1989) J Am Ceram Soc 72:1472

Fukushima K, Yamada I (1989) J Appl Phys 65:619

Regan BO, Graetzel M (1991) Nature (London) 353:737

Bard AJ (1980) Science 207:139

Ha HY, Nam SW, Lim TH, Oh IH, Hong SA (1996) J Membr Sci 111:81

Hoffman MR, Martin ST, Choi W, Bahenmann DW (1995) Chem Rev 95:69

Dervos CT, Thirios EF, Novacovich J, Vassiliou P, Skafidas P (2004) Mater Lett 58:1502

Ye Y, Zhang SC, Dogan F, Schamiloglu E, Gaudet J, Castro P, Roybal M, Joler M, Christodoulou C (2003) 14th IEEE Int 1:719.

Chen XQ, Gu GB, Liu HB, Cao ZN (2004) J Am Ceram Soc 87:1035

Lee KR, Kim SJ, Song JS, Lee JH, Chung YJ, Park S (2002) J Am Ceram Soc 85:341

Kim JH, Fujita S, Shiratori S (2006) Thin Solid Films 499:83

Zhou XS, Lin YH, Li B, Li LJ, Zhou JP, Nan CW (2006) J Phys D 39:558

Hahn H, Logas J, Averback RS (1996) J Mater Res 5:609

Liao SC, Colaizzi J, Chen YJ, Kear BH, Mayo WE (2000) J Am Ceram Soc 83:2163

Angerer P, Yu LG, Khor KA, Krumpel G (2004) Mater Sci Eng A 381:16

Yoshimura M, Bowen HK (1981) J Am Ceram Soc 64:404

Chao S, Petrovsky V, Dogan F (2006) Proceeding of advanced dielectric materials and electronic devices, materials science and technology (MS&T) 2006: materials and systems, vol 1, p 707

Lee YI, Lee JH, Hong SH, Kim DY (2003) Mater Res Bull 38:925

Campbell IE, Sherwood EM (eds) (1967) High-temperature materials and technology. Wiley, New York

Eastman JA (1994) J Appl Phys 75:770

Tobar ME, Krupka J, Ivanov EN, Woode RA (1998) J Appl Phys 83:1604

Tuller HL, Nowick AS (1977) J Phys Chem Solids 38:859

Yan MF, Cannon RM, Bowen HK (1983) J Appl Phys 54:764

Wang QL, Varghese O, Grimes CA, Dickey EC (2007) Solid State Ion 178:187

Guo X, Maier J (2001) J Electrochem Soc 148:E121

Macdonald JR (1987) Impedance spectroscopy: emphasizing solid materials and systems. Wiley, New York

Wynblatt P, Rohrer GS, Papillon F (2003) J Eur Ceram Soc 23:2841

Bak T, Nowotny J, Rekas M, Sorrell CC (2003) J Phys Chem Solids 64:1043

Hoshino K, Peterson NL, Wiley CL (1985) J Phys Chem Solids 46:1397

Pullar RC, Penn SJ, Wang XR, Reaney IM, Alford NM (2009) J Eur Ceram Soc 29:419

Song SH, Wang X, Xiao P (2002) Mater Sci Eng B 94:40

Morse CT, Hill GJ (1970) Proc Br Ceram Soc 18:23

Young AL, Hilmas GE, Zhang SC, Schwartz RW (2007) J Mater Sci 42:5613. doi:10.1007/s10853-006-1116-2

Beauchamp EK (1971) J Am Ceram Soc 54:484

Tunkasiri T, Rujijanagul G (1996) J Mater Sci Lett 15:1767

Yang Y (2003) Master Thesis, University of Missouri-Rolla

Carabajar S, Olagnon C, Fantozzi G, Gressus CL (1995) IEEE Annu Rep 11:278

Souni ME, Oja I, Krunks M (2004) J Mater Sci Mater Electron 15:341

Kishimoto A, Koumoto K, Yanagida H (1989) J Am Ceram Soc 72:1373

McPherson J, Kim JY, Shanware A, Mogul H (2003) Appl Phys Lett 82:2121

Owate IO, Freer R (1992) J Appl Phys 72:2418

Acknowledgements

The authors would like to thank Dr. Wayne Huebner and Dr. Robert Schwartz (Missouri University of Science and Technology) for their valuable suggestions. This work was supported by a MURI program sponsored by Office of Naval Research under Grant No. N000-14-05-1-0541.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chao, S., Petrovsky, V. & Dogan, F. Effects of sintering temperature on the microstructure and dielectric properties of titanium dioxide ceramics. J Mater Sci 45, 6685–6693 (2010). https://doi.org/10.1007/s10853-010-4761-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4761-4