Abstract

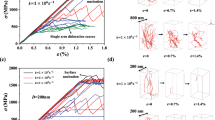

Data in the literature on the effect of grain size from micrometers to nanometers on the flow stress, dislocation density, apparent activation volume and strain rate sensitivity parameters for Cu are analyzed to determine the rate-controlling mechanism. Accord occurs for the intersection of dislocations over the entire grain size range from 10 nm to 150 μm. The dislocation density and its structure and the related Friedel factor are important parameters.

Similar content being viewed by others

References

Conrad H, Jung K (2005) Mater Sci Eng A406:78

Shen YF, Lu L, Lu Q, Jin A, Lu K (2005) Scripta Mater 52:989

Lu L, Chen X, Huang, Lu K (2009) Science 323:607

Armstrong RW (1970) In: Herman H (ed) Adv Mater Res. Wiley, New York, p 101

Armstrong RW (1972) In: Vasu KI, Raman K, Sastry D, Prasad Y (eds) Defect structures in solids. Indian Institute of Science, Bangalore, p 306

Armstrong RW, Rodriguez P (2006) Phil Mag 86:5787

Conrad H (2003) Mater Sci Eng A341:216

Conrad H (2004) Metall Mater Trans A 35A:2618

Conrad H (2007) Nanotechnology 18:325701

Embury JD, Lahaie DJ (1993) In: Natasi M et al (eds) Mechanical properties and deformation behavior of materials having ultrafine microstructure. Kluwer-Academic, Dordrech, p 287

Conrad H, Yang Di (2002) J Electron Mater 33:304

Conrad H, Jung K (2005) Scripta Mater 53:581

Conrad H, Jung K (2006) J Mech Behav Mater 17:337

Conrad H (1965) In: Zackay VF (ed) High-strength materials. John Wiley, New York, p 436

Conrad H, Cao W-d (1996) In: Arsenault RJ et al (eds) The Johannes Weertman Symposium. TMS, Warrendale, PA, p 321

Conrad H, Meester B, Yin C, Doner M (1975) In: Mukerjee AK, Li JCM (eds) Rate processes in plastic deformation of materials. ASM Materials Park, OH, p 175

Doner M, Cheng H, Conrad H (1974) J Mech Phys Solids 22:555

Li JCM (1963) Trans TMS AIME 227:239

Conrad H (1963) In: Thomas G, Washburn J (eds) Electron microscopy and strength of crystals. Interscience Publication, New York, p 299

Conrad H (1970) In: Burke J, Reed MG, Weiss V (eds) Ultrafine-grain metals. Syracuse University Press, New York, p 213

Ashby MF (1970) Philos Mag 21:399

Gordon P (1955) Trans AIME 203:1043

Clareborough LM, Hargreaves ME, Lorretto MH (1958) Acta Metall 6:725

Bailey JE (1963) Philos Mag 8:223

Staker MR, Holt DL (1972) Acta Metall 20:569

Hanson N, Ralph B (1982) Acta Metall 30:411

Hommel M, Kraft O (2001) Acta Mater 49:3935

Ungár T, Oth S, Sanders P, Borbely A, Weertman JR (1998) Acta Mater 446:3693

Zheng Y, Tao N, Lu K (2008) Acta Mater 56:2429

Balogh L, Ungár T, Zhao Y, Zhu Y, Horita Z, Yu C, Langdon T (2008) Acta Mater 56:809

Brandstetter S, Derlet PM, Van Petegem S, Van Swygenhoven H (2008) Acta Mater 56:165

Li YS, Zhang Y, Tao N, Lu K (2009) Acta Mater 57:761

Carreker RP, Hibbard WR (1935) Acta Mater 1:656

Lu L, Dao M, Zhu T, Li J (2009) Scripta Mater 60:1062

Friedel J (1967) Dislocations. Pergamon Press, New York

Hirth JP, Lothe J (1968) Theory of dislocations. McGraw-Hill, New York

Hull D, Bacon O (1984) Introduction to dislocations, 3rd edn. Pergamon Press, New York

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Conrad, H., Yang, D. On the rate-controlling mechanism during the plastic deformation of nanocrystalline Cu. J Mater Sci 45, 6166–6169 (2010). https://doi.org/10.1007/s10853-010-4703-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4703-1