Abstract

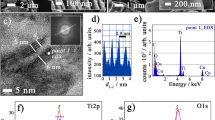

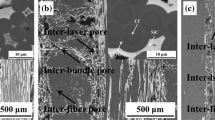

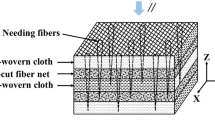

The authors have examined the fabrication conditions of SiC composites containing carbon nanofiber, i.e., vapor-grown carbon nanofiber (VGCF), to enhance the fracture toughness. Commercially available ultrafine SiC powder (specific surface area: 47.5 m2 g−1) was mixed with VGCF and sintering aid in the Al4C3–B4C system. Approximately 1.5 g of the mixture was uniaxially pressed at 50 MPa to obtain a compact with a diameter of 20 mm and a thickness of approximately 1.5 mm. The resulting compact was hot-pressed at 1800 °C for 1 h in Ar atmosphere under a pressure of 62 MPa. The relative density of hot-pressed SiC composite decreased from 98.0 to 96.3%, whereas the fracture toughness was enhanced from 3.8 to 5.2 MPa m1/2, as the amount of VGCF increased from 0 to 6 mass%. Furthermore, an acid treatment of VGCF was conducted to enhance its dispersibility within the SiC matrix, owing to the formation of COO− groups on the VGCF surface. As a result of this treatment, the relative density and fracture toughness of hot-pressed SiC composite with 6 mass% acid-treated VGCF addition increased to 99.0% and 5.7 MPa m1/2, respectively.

Similar content being viewed by others

References

Somiya S, Inomata Y (eds) (1991) Silicon carbide ceramics. Elsevier Science Publishing, New York

Zhu S, Mizuno M, Kagawa Y, Cao J, Nagano Y, Kaya H (1999) J Am Ceram Soc 82:117

Kameda T, Suyama S, Itou Y, Nishida K (1999) J Ceram Soc Jpn 107:622

Sato M, Itatani K, Tanaka T, Davies IJ, Koda S (2006) J Mater Sci 41:7466. doi:10.1007/s10853-006-0791-3

Hirota K, Hara H, Kato M (2007) Mater Sci Eng 485:216

Jacobsen RL, Tritt TM, Guth JR, Ehrlich AC, Gillespie DJ (1995) Carbon 33:1217

Maensiri S, Laokul P, Kinkaewnarong J, Amornkitbamrung V (2007) Mater Sci Eng 447:44

Uchida T, Anderson DP, Minus ML, Kumar S (2006) J Mater Sci 41:5851. doi:10.1007/s10853-006-0324-0

Sun J, Gao L (2003) Carbon 41:1063

Tomonari Y, Murakami H, Nakashima N (2006) Chem Eur J 12:4027

Ros TG, van Dillen J A, Geus JW, Koningsberger DC (2002) Chem Eur J 5:2868

Itou Y, Kameda T, Nishida K, Umezawa M, Imai K, Ichiikawa H (1998) J Ceram Soc Jpn 106:830

Toebes ML, van Heeswijk JMP, Bitter JH, van Dillen AJ, de Jong KP (2004) Carbon 42:307

Li YH, Wang S, Luan Z, Ding J, Xu C, Wu D (2003) Carbon 41:1057

Kubota S, Nishikiori H, Tanaka N, Endo M, Fujii T (2005) J Phys Chem B 109:23170

Shinozaki S, Williams RM, Juterbock BN, Donlon WT, Hangas J, Peters CR (1985) Am Ceram Soc 64:1389

Williams RM, Juterbock BN, Shinozaki S, Peters CR, Whalen TJ (1985) J Am Ceram Soc 64:1385

Davies IJ, Ishikawa T, Shibuya M, Hirokawa T (1999) Comp Sci Technol 59:801

Akatsu T, Tanabe Y, Yasuda E (1999) J Mater Res 14:1316

Suemasu H, Kondo A, Itatani K, Nozue A (2001) Comp Sci Technol 61:281

Zhou CR, Yu ZB, Krstic VD (2007) J Eur Ceram Soc 27:437

Krstic Z, Yu Z, Krstic VD (2007) J Mater Sci 42:5431. doi:10.1007/s10853-006-0826-9

Acknowledgement

The authors wish to thank Denki Kagaku Kogyo Co., Ltd. (Tokyo, Japan) for providing the B4C powder.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kita, J., Suemasu, H., Davies, I.J. et al. Fabrication of silicon carbide composites with carbon nanofiber addition and their fracture toughness. J Mater Sci 45, 6052–6058 (2010). https://doi.org/10.1007/s10853-010-4690-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4690-2