Abstract

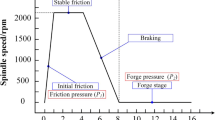

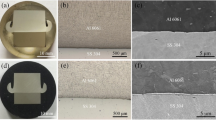

Friction welding of dissimilar metal combination of aluminum alloy and austenitic stainless steel was examined to investigate the effect of welding conditions on mechanical properties of the dissimilar metal combination. The welded joints were produced by varying forge pressure (F g), friction pressure (F r), and burn-off length (B). The joints were subjected to mechanical testing methods such as the tension, notch Charpy impact tests. The tensile strength and toughness decrease with an increase in friction pressure. The tensile strength decreases with an increase in burn-off length at a low forge pressure while tensile strength increases with an increase in burn-off length at a high forge pressure. The tensile failure of the welded joint occurred in aluminum alloy just away from interface in the thermo-mechanically affected zone indicates good joint strength at the condition of low friction pressure, high forge pressure, and high burn-off length. The maximum tensile strength was observed with low friction pressure and high forge pressure. The tensile strength of dissimilar joint is approximately equal to tensile strength of 6063 aluminum alloys at the condition of low friction pressure, high forge pressure, and high burn-off length. The tensile and impact failure of joints was examined under scanning electron microscope and failure modes were discussed.

Similar content being viewed by others

References

Ruge J, Thomas K, Eckel C, Sundaresan S (1986) Weld J 65:28

Kim HJ, Kang JY, Shin YE, Kim DS (1998) Welding handbook. Korea Welding Society, Seoul, p 659

Yılmaz M (1993) Investigation of welding area in the friction welding of tool steels. PhD thesis, Yıldız Technical University, İstanbul, Turkey

Fukumoto S, Tsubakino H, Okita K, Aritashi M, Tomita T (1998) Mater Sci Technol 14:333

Fukumoto S, Tsubakino H, Okita K, Aritashi M, Tomita T (1999) Mater Sci Technol 15:1080

Dunn KA, Tosten MH, Louthan MR, Birt ML (1999) In: 32nd international metallographic society annual convention, OH, USA, 31 Oct–3 Nov, 1999

Fukumoto S, Ohashi M, Tsubakino H, Okita K, Aritoshi M, Tomita T, Goto K (1998) J Jpn Inst Light Met 48(1):36

Ochi H, Ogawa K, Yamamoto Y, Suga Y (1996) J Soc Mater Sci 45(4):459

Sundaresan S, Murti KGK (1993) Join Mater 5(2):66

Yokoyama T, Yamaguchi M (1999) J Jpn Inst Light Met 49(9/11):535

Olorunniwo OE, Atanda PO, Akinluwade KJ (2009) J Miner Mater Charact Eng 8(1):1

Satyanarayana VV, Madhusudhan Reddy G, Mohandas T (2005) J Mater Process Technol 160:128

Yılmaz M, Col M, Acet M (2003) Mater Charact 49:421

Kim S-Y, Jung S-B, Shur C-C (2003) J Mater Sci 38:1281. doi:10.1023/A:1022890611264

Bekir SY, Ahmet ZS, Nafiz K, Ahmed Z (1995) J Mater Process Technol 49:431

Jessop TJ (1995) Friction welding of dissimilar metal combinations-aluminum and stainless steel. Weld Institute Research Report, November 1995, pp 73–75

Fukumoto S, Tsubakino H, Aritoshi M, Tomita T, Okita K (2002) Mater Sci Technol 18:219

Deschamps A, Brechet Y, Guoyat P (1999) In: Proceedings of the seventh seminar of the international federation of heat treatment and surface engineering, Hungary, pp 1–10

Acknowledgments

The authors express their gratitude to Defence Research and Development Organization for the microstructure analysis to carry out this programme. The authors are thankful to Dr. G. Madhusudhan Reddy, DMRL for his continued encouragement. The author also thanks to Prof. K. Prasada Rao (IIT M) for the support to conduct the experimental work. One of the authors (P. Sammaiah) is thankful to the Principal and the management of S.R. Engineering College, Warangal for their continued support during this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sammaiah, P., Suresh, A. & Tagore, G.R.N. Mechanical properties of friction welded 6063 aluminum alloy and austenitic stainless steel. J Mater Sci 45, 5512–5521 (2010). https://doi.org/10.1007/s10853-010-4609-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4609-y