Abstract

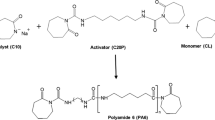

Resin transfer molding (RTM) was used to manufacture all-polyamide (all-PA) composites in which PA6 matrix was in situ formed by the anionic polymerization of ε-caprolactam (CL). Influence of molding temperature (T M), a critical process parameter, on the structure and properties of all-PA composites was investigated using TGA, DSC, SEM, and tensile, flexural test. Increasing T M resulted in the decrease of CL conversion and the enhancement of fiber/matrix interface bonding. By comparing the mechanical properties of all-PA composites prepared at different T M (140–200 °C), an optimal T M (180 °C) was found in this temperature range. As a whole, the complete consolidation of all-PA composites and the remarkable reinforcing effect of PA66 fibers on PA6 matrix were assured by low-void fraction, high-CL conversion and strong interface performance though in a wide T M range.

Similar content being viewed by others

References

Capiati NJ, Porter RS (1975) J Mater Sci 10:1671. doi:10.1007/BF00554928

Abo El-Maaty MI, Bassett DC, Olley RH, Hine PJ, Ward IM (1996) J Mater Sci 31:1157. doi:10.1007/BF00353094

Alcock B, Cabrera NO, Barkoula NM, Loos J, Peijs T (2006) Composites A 37:716

Alcock B, Cabrera NO, Barkoula NM, Spoelstra AB, Loos J, Peijs T (2007) Composites A 38:147

Kim KJ, Yu WR, Harrison P (2008) Composites A 39:1597

Li HH, Zhang XQ, Duan YX, Wang DJ, Li L, Yan SK (2004) Polymer 45:8059

Hine PJ, Broome V, Ward IM (2005) Polymer 46:10936

Mead WT, Porter RS (1978) J Appl Polym Sci 22:3249

Kabeel MA, Bassett DC, Olley RH, Hine PJ, Ward IM (1994) J Mater Sci 29:4694. doi:10.1007/BF00356511

Stern T, Marom G, Wachtel E (1997) Composites A 28:431

Maity J, Jacob C, Das CK, Alam S, Singh RP (2008) Polym Test 27:581

Yao DG, Li RH, Nagarajan P (2006) Polym Eng Sci 46:1223

Hine PJ, Ward IM (2004) J Appl Polym Sci 91:2223

Gilbert JL, Ney DS, Lautenschlager EP (1995) Biomaterials 16:1043

Wright DD, Lautenschlager EP, Gilbert JL (2005) J Mater Sci Mater Med 16:967

Qin C, Soykeabkaew N, Ni XY, Peijs T (2008) Carbohydr Polym 71:458

Izer A, Bárány T, Varga J (2009) Compos Sci Technol 69:2185

Lacroix F, Lu HQ, Schulte K (1999) Composites A 30:369

Cohen Y, Rein DM, Vaykhansky LE, Porter RS (1999) Composites A 30:19

Teckoe J, Olley RH, Bassett DC, Hine PJ, Ward IM (1999) J Mater Sci 34:2065. doi:10.1023/A:1004555608836

Cabrera NO, Alcock B, Peijs T (2008) Composites B 39:1183

Kim GM, Michler GH, Ania F, Calleja FJB (2007) Polymer 48:4814

Hine PJ, Ward IM (2006) J Appl Polym Sci 101:991

Gong Y, Yang GS (2009) J Mater Sci 44:4639. doi:10.1007/s10853-009-3708-0

Goettler LA, Neff WJ (1986) Polym Compos 7:383

Pillay S, Vaidya UK, Janowski GM (2005) J Therm Compos Mater 18:509

Hedrick RM, Richard WR Jr (1968) US Patent 3,419,517

Leclerc JS, Ruiz E (2008) Composites A 39:1859

Zhang CL, Feng LF, Hu GH (2006) J Appl Polym Sci 101:1972

Rijswijk K, Bersee HEN, Beukers A, Picken SJ, Geenen AA (2006) Polym Test 25:392

Hine PJ, Ward IM, Jordan ND, Olley R, Bassett DC (2003) Polymer 44:1117

Li YL, Yang GS (2004) Macromol Rapid Commun 25:1714

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gong, Y., Yang, G. All-polyamide composites prepared by resin transfer molding. J Mater Sci 45, 5237–5243 (2010). https://doi.org/10.1007/s10853-010-4565-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-010-4565-6