Abstract

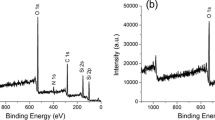

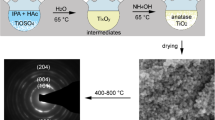

Mesoporous titania–silica composite with large primary particles and homogeneous dispersion of Ti in the silica matrix were synthesized by the sol–gel method via a one-pot co-condensation method using cetyltrimethylammonium bromide (CTAB) as a structure-directing agent. Freshly prepared titanium oxychloride (TiOCl2, titania precursor that is relatively stable) and sodium silicate were used as titania and silica precursors (at the initial ratio of Ti:Si = 1), respectively. The final products were obtained after removing the template by calcination and had overall ratio of Ti:Si = 2:3 (based on EDS and XRF analyses). Other characterization techniques employed include FE-SEM, TEM, FT-IR, DTGA, and nitrogen physisorption studies. The textural properties of the products were highly influenced by the molar concentration of CTAB. Materials with large primary particles (submicrometer-scale dimensions) were obtained at higher concentrations of CTAB (1.7 wt%). The porosities of the templated material were highly reduced compared to that of the untemplated material, emphasizing the influence of Ti loading in the silica matrix. Both pore size and surface area increased at a calcination temperature of 550 °C. The DTGA result showed that the composites exhibited elevated thermal stability (up to 900 °C). In summary, mesoporous titania–silica composite with desirable properties were developed via the proposed method using a relatively inexpensive silica precursor.

Similar content being viewed by others

References

Stokke JM, Mazyck DW (2008) Environ Sci Technol 42:3808

Song X, Gao L (2007) J Phys Chem C 111:8180

Galindo IR, Viveros T, Chadwick D (2007) Ind Eng Chem Res 46:1138

Wang J, Kuhn J, Lu X (1995) J Non-Cryst Solids 186:296–300

Mdoe JEG, Macquarrie DJ (2005) Int J Sci Res 14:23

Mitrikas G (1998) J Non-Cryst Solids 224:17–22

Delsannti M, Moussaid A, Munch JP (1993) J Colloid Interf Sci 157:285

Reiche MA, Ortelli E, Baiker A (1999) Appl Catal B 23:187

Nishikida K, Iwamoto R (1986) The analysis of material by infrared spectroscopy. Kodansya, Tokyo, p 209

Kim JM, Stucky GD (2000) Chem Commun 1159–1160

Barrett EP, Joyner LG, Halenda PP (1951) J Am Chem Soc 73:373

Pesquera C, González F, Blanco C, Sanchez L (2004) Appl Surf Sci 238:320

Sierra L, Guth JL (1999) Microp Mesop Mater 27:243

Matos JR, Mercuri LP, Kruk M, Jaroniec M (2002) Langmuir 18:884

Zaki MI, Vielhaber B, KnOzinger H (1986) J Phys Chem 90:3176

Yu JC, Yu J, Zhao J (2002) Appl Catal B Environ 36:31

Lee JH, Yang YS (2005) J Mater Sci 40:2843. doi:10.1007/s10853-005-2434-5

Shen S, Deng Y, Zhu G, Mao D, Wang Y, Wu G, Li J, Liu X, Lu G, Zhao D (2007) J Mater Sci 42:7057. doi:10.1007/s10853-007-1608-8

Wang HN, Yuan P, Zhou L, Guo YN, Zou J, Yu AM, Lu GQ, Yu CZ (2009) J Mater Sci 44:6484. doi:10.1007/s10853-009-3578-5

Berube F, Kleitz F, Kaliaguine S (2009) J Mater Sci 44:6727. doi:10.1007/s10853-009-3566-9

Gao X, Wachs IE (1999) Catal Today 51:233

Sing KSW, Everett DH, Haul RAW, Moscou L, Pierotti RA, Rouquerol J, Siemieniewska T (1985) Pure App Chem 57(4):603–619

Hilonga A, Kim JK, Sarawade PB, Kim HT (in press) J Mater Sci. doi:10.1007/s10853-009-4076-5

Kresge CT, Leonowicz ME, Roth WJ, Vartuli JC, Beck JS (1992) Nature 359:710

Linden M, Schunck SA, Schüth F (1998) Angew Chem Int Ed Engl 37:82

Sicard L, Frasch J, Soulard M, Lebeau B, Patarin J, Davey T, Zana R, Kolenda F (2001) Microp Mesop Mater 44–45:25

Zhang J, Carl PJ, Zimmermann H, Goldfarb D (2002) J Phys Chem B 106:5382

Ying JY, Mehert CP, Wong MS (1998) Angew Chem Int Ed Engl 37:82

Sicard L, Lebeau B, Patarin J, Zana R (2002) Langmuir 18:74

Patarin J, Lebeau B, Zana R (2002) Curr Opin Colloid Interf Sci 7:107

Vautier-Giongo C, Pastore HO (2006) J Colloid Interf Sci 299:874

Khalil KMS, Zaki MI (1997) Powder Technol 92:233

Zhao L, Yu J, Chen B (2005) J Solid State Chem 178:1818

Yu JG, Yu HG, Cheng B, Zhao XJ, Yu JC, Ho WK (2003) J Phys Chem B 107:13871

Groen JC, Peffer LAA, Perez-Ramirez J (2003) Micropor Mesopor Mater 60(1–3):1

Acknowledgements

We would like to thank the Ministry of Commerce and Industries of the Republic of Korea for financial support under the R & D Innovation Fund for Small and Medium Business Administration (Project Application No. S1017370).

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Hilonga, A., Kim, JK., Sarawade, P.B. et al. Mesoporous titania–silica composite from sodium silicate and titanium oxychloride. Part II: one-pot co-condensation method. J Mater Sci 45, 1264–1271 (2010). https://doi.org/10.1007/s10853-009-4077-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-4077-4