Abstract

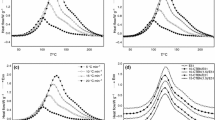

The interpenetrating polymer networks (IPNs) were formed by unsaturated polyester resin (UPR) polymerized by free radical initiators: benzoyl peroxide (BPO) or cumene hydroperoxide (CHP) and epoxy polyester (EP), cured with acid anhydrides: tetrahydrophthalic anhydride (THPA) or maleic anhydride (MA). IPNs consisting 10, 30, 50, 70, 90 wt% of EP were prepared. The effect of the EP component in the IPNs and the type of curing agent on the cure behavior, thermal, and viscoelastic properties have been investigated. The results showed that both EP content and used curing system influenced on studied properties. As the EP content increased, the glass transition temperatures (T g) also increased. Moreover, higher values of tanδmax and lower values of cross-linking density in a rubbery state (νe) of IPNs containing higher EP content, probably due to plasticization effect of EP component were observed. Additionally, more heterogeneous network structure (higher values of the full-width at half-maximum (FWHM) as the EP content decreased was prepared. The thermal and viscoelastic properties of the blends cured with BPO/MA or CHP/MA system were considerably better than those cured with BPO/THPA or CHP/THPA. The higher stiffness, νe, T g and lower tanδmax values were obtained. It was probably connected with the interactions of carbon–carbon double bonds of MA with vinyl monomer (styrene), UPR and radical initiators causing to obtain more cross-linked polymer network structure. This supposition was confirmed on basis of the cure reaction monitored by DSC. The chemical interactions between two components of the blends and epoxy hardener caused that the BPO/MA or CHP/MA cure systems influenced on the cure behavior of UPR and EP components in the IPNs. The exotherm peak temperature (T max1) shifted to lower values compared to these in the neat UPR whilst T max2 shifted to higher values than in the neat EP. However, the cure behavior of the UPR was not greatly affected by the presence of EP component when BPO/THPA or CHP/THPA cure systems were used due to the lack of chemical interactions between the components and their curatives.

Similar content being viewed by others

References

Burns R (1982) Polyester molding compounds. Marcel Dekker, New York

Lubin G (ed) (1969) Handbook of fiber glass and advanced plastics composites. Van Nostrand Reinhold, New York

Riew CK, Gillham K (eds) (1984) Rubber modified thermoset resins. Advances in chemical science. American Chemical Society, Washington DC, p 208

Paul DR, Newman S (eds) (1978) Polymer blends, vol 2. Academic Press, New York

Qipeng G, Haifeng Z, Sixun Z, Yongli M, Wei Z (1999) J Mater Sci 34:123. doi:10.1023/A:1004486129169

Mouritz AP, Mathys Z (1999) Compos Struct 47:643

Egglestone GT, Turley DM (1994) Fire Matter 18:255

Lubin G (ed) (1982) Handbook of composites. Van Nostrand, New York, p 17

Liu M-S, Liu Ch-Ch, Lee Ch-T (1999) J Appl Polym Sci 72:585

Shaker ZG, Browne RM, Stretz HA, Cassidy PE, Blanda MT (2002) J Appl Polym Sci 84:2283

Park SJ, Park WB, Lee JR (1999) Polym J 31:28

Dinakaran K, Alagar M (2002) J Appl Polym Sci 85:2853

Dinakaran K, Alagar M (2002) J Appl Polym Sci 86:2502

Chou YC, Lee LJ (1994) Polym Eng Sci 34:1239

Ludovic V, Hsu Ch-P (1999) Polymer 40:2059

Xu MX, Xiao JS, Zhang WH, Yao KD (1994) J Appl Polym Sci 54:1659

Xu MX, Liu WG, Guan YL, Bi ZP, DeYao K (1995) Polymer Int 38:205

Benny CA, Abraham Beena T, Thomas TE (2006) J Appl Polym Sci 100:449

Suspene L, Show Yang Y, Pascault J-P (1993) In: Keith Riew C, Kinloch AJ (eds) Rubber toughened plastics. Advances in chemistry. American Chemical Society, Washington, DC, p 168

Lin MS, Jeng KT, Huang KY, Shin YF (1993) J Polym Sci Polym Chem Ed 31:3317

Sperling LH, Mishra V (1995) Polym Adv Technol 7:197

Dean K, Cook WD, Zipper MD, Burchill P (2001) Polymer 42:1345

Worzakowska M (2008) J Therm Anal Calorim 93:799

Penczek P, Bończa-Tomaszewski Z, Bańkowska A (2002) Macromol Symp 187:243

Bończa-Tomaszewski Z, Penczek P, Bańkowska A (2006) Surf Coat Int B Coat Trans 89:157

Worzakowska M (2008) J Appl Polym Sci 110:3582

Yang H, Lee J (2000) J Appl Polym Sci 79:1230

Stevens GC (1981) J Appl Polym Sci 26:4256

Park WH, Lee JK, Kwan KI (1996) Polym J 28:407

Yang YS, Lee LJ (1987) Macromolecules 20:1490

Jin SR, Widmaier JM, Meyer GC (1988) Polymer 29:346

Ward IM (1971) Mechanical properties of solid polymer. John Wiley& Sons, London, p 77

Tobolsky AV, Carlson DW, Indicator NJ (1961) J Polym Sci 54:175

Charlesworth JM (1988) Polym Eng Sci 28:230

Treloar LRG (1958) The physics of rubber elasticity. Oxford University Press, London

Elliot JE, Nie J, Bowman CN (2002) Polymer 44:327

Barral L, Cano J, López J, López-Bueno I, Nogueira P, Abad MJ, Ramirez C (2000) J Therm Anal Cal 60:391

Shimbo M, Ochi M, Iesako H (1984) J Polym Sci Polym Phys Edn 22:1461

Ochi M, Iesako H, Nakajima S, Shimbo M (1984) J Polym Sci Polym Phys Edn 24:251

Fox TG, Loshaek S (1955) J Polym Sci 15:371

Bicerano J, Sammler RL, Carriere CJ, Seitz JT (1996) J Polym Sci B: Polym Phys 34:2247

Zheng H, Zheng S, Guo Q (1997) J Polym Sci Polym Chem Ed 35:3161

Cook WD, Forsythe JS, Scott TF, Quay-Thevenon S (2004) J Appl Polym Sci 93:1348

Simon GP, Allen PEM, Wiliams DRG, Cook WD (1991) Polymer 32:2577

Allen PEM, Wiliams DRG, Clayton AB (1994) Eur Polym J 30:427

Kannurpatti AR, Anseth JW, Bowman CN (1998) Polymer 39:2507

Park WH, Lenz RW, Goodwin S (1999) Polym Degrad Stabil 63:287

Grassie N, Murry EJ, Holmes PA (1984) Polym Degrad Stabil 6:95

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Worzakowska, M. Thermal and dynamic mechanical properties of IPNS formed from unsaturated polyester resin and epoxy polyester. J Mater Sci 44, 4069–4077 (2009). https://doi.org/10.1007/s10853-009-3587-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3587-4