Abstract

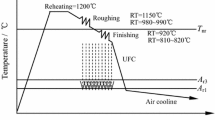

The microstructural evolution during continuous cooling has been investigated in an ultralow-C and high-Nb containing steel and compared to that of a traditional Nb–Mo pipeline steel. The deformation promotes the formation of fine-grained quasi-polygonal and acicular ferrite in coarse grain sized austenite. Lowering the austenite grain size leads to a loss in hardenability of austenite despite the fact that grain sizes of the final microstructure are refined. The high-Nb and Nb–Mo bearing materials have the nearly same effect on lowering the onset temperatures of transformation, but the former is somewhat faster in the progress of transformation due to an additional work-hardening effect. Thus, to obtain sufficient amounts of ultrafine-grained acicular ferrite, cooling rate must be increased to suppress the formation of high-temperature transformed products in high-Nb materials.

Similar content being viewed by others

References

Smith YE, Coldren AP, Cryderman RL (1972) Toward improved ductility and toughness. Climax Molybdenum Company (Japan) Ltd, Tokyo

Kim YM, Kim SK, Lim YJ et al (2002) ISIJ Int 42:1571

Smith Y, Coldren A, Cryderman R (1976) Met Sci Heat Treat 18:59

Zhao MC, Shan YY, Xiao FR et al (2003) Mater Lett 57:1496

Kong JH, Zhen L, Guo B et al (2004) Mater Des 25:723

Tang ZH, Stumpf W (2008) Mater Charact 59:717

Hulka K, Bordigon P, Gray M (2006) Microalloy Technol 6:1

Stalheim DG, Barnes KR, Mccutcheon DB (2006) Microalloy Technol 6:15

Suehiro M, Liu Z-K, Ågren J (1996) Acta Mater 44:4241

Suehir M (1998) ISIJ Int 38:547

Siciliano F Jr, Jonas JJ (2000) Metall Mater Trans A31:511

Bengochea R, Lápez B, Gutierrez I (1999) ISIJ Int 39:583

Kvackaj T, Mamuzic I (1998) ISIJ Int 38:1270

Subramanian SV, Zeng X, Collins LE et al (1993) In: Asfahani R, Tither G (ed) Proceedings of international symposium on ‘Low carbon steels for the 90’s’. TMS, Pittsburgh

Sellars CM (1985) In: Gray JM et al (ed) Proceedings of international conference on ‘HSLA steels: metallurgy and applications’. Beijing

Acknowledgements

This study was financially supported by the National Natural Science Foundation of China under contract No. 50504007 and the National Key Project of Scientific and Technical Supporting Programs (No. 2007BAE51B07). This study also was supported by Benxi Iron and Steel Corp., China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, Y.B., Yu, Y.M., Xiao, B.L. et al. Microstructural evolution in an ultralow-C and high-Nb bearing steel during continuous cooling. J Mater Sci 44, 3928–3935 (2009). https://doi.org/10.1007/s10853-009-3526-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3526-4