Abstract

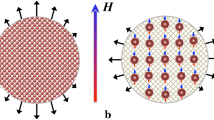

The results presented refer to the structure analysis of magnetorheological elastomers (MREs), based on ferromagnetic particles in a polyurethane matrix. The influence of the volume fraction of the ferromagnetic particles on their arrangement in relation to the external magnetic field was investigated. The amount of carbonyl iron particles, of the average size 6–9 μm, varied from 1.5 to 33 vol.%. Scanning electron microscopy was used to observe magnetorheological elastomer microstructures. Image analysis has been applied to describe the microstructures. From author’s previous studies it is known that the microstructure anisotropy has significant effect on the properties of magnetorheological elastomers. Two different techniques of image analysis: skeleton by influence zone method and linear covariance function were used to reveal the anisotropy in particle arrangements. These methods allowed quantitative microstructure description. The results show that particle arrangement changes with their volume fraction. The analyses confirm particle chain networks in composites with higher iron content. Differences in particles arrangement for samples prepared under diverse conditions were also clearly shown.

Similar content being viewed by others

References

Zhou GY (2003) Smart Mater Struct 12:139

Farshad M, Benine A (2004) Polym Test 23:347

Jolly MR, Carlson JD, Munoz BC, Bullions TA (1996) J Intell Mater Syst Struct 7:613

Khoo M, Liu C (2001) Sens Actuators A Phys 89:259

An Y, Shaw MT (2003) Smart Mater Struct 12:157

Lokander M, Stenberg B (2003) Polym Test 22:245

Varga Z, Filipcsei G, Zrinyi M (2005) Polymer 46:7779

Liu B, Shaw MT (2001) J Intell Mater Syst Struct 12:57

Lokander M, Stenberg B (2003) Polym Test 22:677

Boczkowska A, Awietjan S, Babski K, Wróblewski R, Leonowicz M (2006) Effect of the processing conditions on the microstructure of urethane magnetorheological elastomers. In: William D Armstrong (ed) Smart structures and materials 2006: active materials: behavior and mechanics. Proceedings of SPIE, vol 6170, p 28

Boczkowska A, Awietjan SF, Wróblewski R (2007) Smart Mater Struct 16:1924

Boczkowska A, Awietjan SF (2008) Mater Sci Forum 587–588:630

Wojnar L, Majorek M (1994) Computer based image analysis. FOTOBIT-DESIGN S.C. 87–91

Susagna F, Yotte S, Riss J, Breysse D, Ghosh S (2000) Covariance and spatial distribution of particles in metal matrix composite. In: Proceedings of 6th international conference on stereology and image analysis in materials science. Stermat. Cracow, Poland, pp 397–402

Niezgoda T, Szymczyk W, Boczkowska A (2008) J KONES Powertrain Transp 15:385

Acknowledgements

This study was financed as a Targeted Research Project from funds of the Polish Ministry of Science and Higher Education within years 2006–2008.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Boczkowska, A., Awietjan, S.F., Wejrzanowski, T. et al. Image analysis of the microstructure of magnetorheological elastomers. J Mater Sci 44, 3135–3140 (2009). https://doi.org/10.1007/s10853-009-3417-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3417-8