Abstract

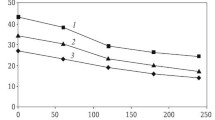

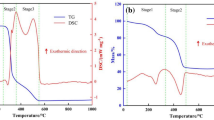

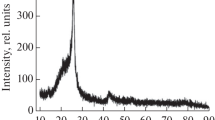

Porous yttria-stabilized zirconia (YSZ) substrates with volume fractions of porosity ranging from 28.9 to 53 vol.% were developed using starch as a fugitive additive. Concentrated aqueous YSZ slips with different amounts of starch and an acrylic latex binder were prepared. The influence of the volume fraction of starch and sintering temperature on the sintering behavior and final microstructure were investigated. Two kinds of pores were observed in the sintered tapes: large pores created by the starch particles with lengths between 15 and 80 μm and smaller pores in the matrix with lengths between 0.6 and 3.8 μm. The porosities were above those predicted for each of the starch contents. However, larger deviations from the predicted porosity were found as more starch was added. The top surface of the sintered tapes had a greater porosity than the bottom one for all the starch contents examined. The total porosity and the percentage of open porosity in the sintered tapes could be controlled by the volume fraction of added starch as well as by the sintering temperature. The open pores between the YSZ particles were removed by sintering at 1600 °C. As the volume fraction of starch increased from 17.6 to 37.8 vol.%, there was a gradual increase in the interconnectivity of the pore structure.

Similar content being viewed by others

References

Ishizaki K, Komarneni S, Nauko M (1998) Porous materials process technology and applications. Kluwer, London

Saggio-Woyanski RJ, Scott CE, Minnear WP (1992) Am Ceram Soc Bull 71:1674

Rambo CR, Cao J, Seiber H (2004) Mater Chem Phys 87:345

Boaro M, Vohs JM, Gorte RJ (2003) J Am Ceram Soc 86(3):395

Prathar SK, Dassharma A, Maiti HS (2007) J Mater Sci 42(17):7220. doi:https://doi.org/10.1007/s10853-007-1497-x

Jiang SP, Chan SH (2004) J Mater Sci 39(14):4405. doi:https://doi.org/10.1023/B:JMSC.0000034135.52164.6b

Corbin SF, Apté PS (1999) J Am Ceram Soc 82(7):1693

Zivcova Z, Gregorová E, Pabst W (2007) J Mater Sci 42(20):8760. doi:https://doi.org/10.1007/s10853-007-1852-y

Gregorová E, Pabst W, Bohačenko I (2006) J Eur Ceram Soc 26:1301

Gregorová E, Pabst W (2007) J Eur Ceram Soc 27:669

Moreno R (1992) Am Ceram Soc Bull 71(11):1647

Moreno R (1992) Am Ceram Soc Bull 71(10):1521

Kristofferen A, Roncari E, Galassi C (1998) J Eur Ceram Soc 18:2123

Pagnoux C, Chartier T, de Granja MF, Doreau F, Ferreira JM, Baumard JF (1998) J Eur Ceram Soc 18:241

Albano MP, Genova LA, Garrido LB, Plucknett K (2008) Ceram Int 34:1983

Smay JE, Lewis JA (2001) J Am Ceram Soc 84(11):2495

Kolar D (1979) Mater Sci Res 13:335

Gregorová E, Zivcova Z, Pabst W (2006) J Mater Sci 41(18):6119. doi:https://doi.org/10.1007/s10853-006-0475-z

Díaz A, Hampshire S (2004) J Eur Ceram Soc 24:413

Lyckfeldt O, Ferreira JMF (1998) J Eur Ceram Soc 18:131

Martinez CJ, Lewis JA (2002) J Am Ceram Soc 85(10):2409

Acknowledgements

The authors would like to acknowledge CONICET (Argentina), NSERC (Canada), and CNPq (Brazil) for provision of research funding through the Inter-American Research in Materials (CIAM) Program. We also acknowledge the support of the Canada Foundation for Innovation, the Atlantic Innovation Fund, and other partners who helped fund the Facilities for Materials Characterization, managed by the Dalhousie University Institute for Materials Research, who provided access to the FE-SEM.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Albano, M.P., Garrido, L.B., Plucknett, K. et al. Influence of starch content and sintering temperature on the microstructure of porous yttria-stabilized zirconia tapes. J Mater Sci 44, 2581–2589 (2009). https://doi.org/10.1007/s10853-009-3337-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3337-7