Abstract

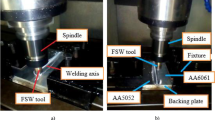

This research aimed to weld dissimilar metals joints, AA6061 aluminum alloy and SS400 low-carbon steel, and find the optimum operating conditions of friction stir welding. In dissimilar metals butt joint by friction stir welding procedures, there are four major controllable factors, which are tool rotation speed, transverse speed (feed rate), tool tilt angle with respect to the workpiece surface and pin tool diameter. Understandably, not all the controllable factors are included in this article. The quality of dissimilar metals butt joints is evaluated by the impact value, which has not been discussed in literatures. In addition, an uncontrollable parameter, which is the tensile strength, is used to double-check its quality based on the excellent impact value. Analysis of variance (ANOVA) is used to analyze the experimental data. The Taguchi technique with ANOVA is also used to determine the significant factors of performance characteristics. The results are expected to serve as references to overland and aquatic transportation machines for weight reduction.

Similar content being viewed by others

References

Thomas WM (1995) GB Patent Application 91259788 (1991). US Patent 5460317

Chien CH, Chen TP, Chao YJ (2005) J CSME 26:195

Chien CH, Chen TP, Lin WB, Chao YJ (2006) J CSME 27:663

Steuwer A, Peel MJ, Withers PJ (2006) Mater Sci Eng A 441:187

Karlsson L, Berqvist EL, Larsson H (2002) Weld World 46:10

Lee WB, Jung SB (2004) Mater Res Innov 8:93

Ouyang J, Yarrapreddy E, Kovacevic R (2006) J Mater Process Technol 172:110

Uzun H, Dalle Donne C, Argagnotto A, Ghidini T, Gambaro C (2005) Mater Design 26:41

Watanable T, Takayama H (2006) J Mater Process Technol 178:342

Lee WB, Schmuecker M, Mercardo UA, Biallas G, Jung SB (2006) Scr Mater 55:355

Ross PJ (1996) Taguchi techniques for quality engineering. McGraw-Hill, New York

Acknowledgements

The author gratefully acknowledges the financial support received from the National Science Council (grant no. 96-2221-E-268-003), and the National Center for High Performance Computing of the Republic of China.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, T. Process parameters study on FSW joint of dissimilar metals for aluminum–steel. J Mater Sci 44, 2573–2580 (2009). https://doi.org/10.1007/s10853-009-3336-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-009-3336-8