Abstract

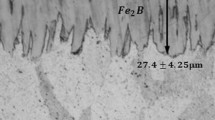

Glow discharge (GD) nitrocarburizing, at low-carbon content and different working temperatures, was performed on AISI 316L and AISI 304 stainless steels. Structural compositions were studied by X-ray diffraction. Instrumented indentation and conventional Vickers method allowed hardness profiles to be determined. Tribological behavior was studied by means of reciprocating sliding and nanoscratch tests. After nitrocarburizing, both steels showed similar embedded nitride and carbide formations. The layer formed by GD in nitrogen–carbon atmosphere is thicker than those consisting solely of nitrogen particularly for AISI 316L. At working temperatures higher than 400 °C, roughness increased and wear was limited to asperity compaction. Wear mechanisms were similar in both steels. However, wear was reduced by up to a factor of 5 in treated steels. No difference in elastic surface recovery was observed after nitrocarburizing in either steel.

Similar content being viewed by others

References

Jones AM, Bull SJ (1996) Surf Coat Technol 83:269

Blawert C, Weisheit A, Mordike BL, Knoop FM (1996) Surf Coat Technol 85:15

Larisch B, Brusky U, Spies HJ (1999) Surf Coat Technol 116–119:205

Blawert C, Mordike BL, Collins GA, Short KT, Jirásková Y, Schneeweiss O, Perina V (2000) Surf Coat Technol 128–129:219

Hanninen H, Romu J, Ilola R, Tervo J, Laitinen A (2001) J Mater Process Technol 117:424

Tsujikawa M, Yamauchi N, Ueda N, Sone T, Hirose Y (2005) Surf Coat Technol 193:309

Sun Y (2005) J Mater Process Technol 168:189

Foerster CE, Serbena FC, da Silva SLR, Lepienski CM, Siqueira CJM, Ueda M (2007) Nucl Instrum Methods Phys Res B 257:732

Foerster CE, Souza JFP, Silva CA, Ueda M, Kuromoto NK, Serbena FC, Silva SLR, Lepienski CM (2007) Nucl Instrum Methods Phys Res B 257:727

Oddershede J, Christiansen TL, Stahl K, Somers MAJ (2008) J Mater Sci 43:5358. doi:https://doi.org/10.1007/s10853-008-2791-y

da Silva LLG, Ueda M, Mello CB, Codaro EN, Lepienski CM (2008) J Mater Sci 43:5989. doi:https://doi.org/10.1007/s10853-008-2768-x

Paternoster C, Fabrizi A, Cecchini R, El Mehtedi M, Choquet P (2008) J Mater Sci 43:3377. doi:https://doi.org/10.1007/s10853-007-2392-1

Li CX, Dong H, Bell T (2006) J Mater Sci 41:6116. doi:https://doi.org/10.1007/s10853-006-0484-y

Dasgupta A, Kuppusami P, Vijayalakshmi M, Raghunathan VS (2007) J Mater Sci 42:8447. doi:https://doi.org/10.1007/s10853-007-1783-7

Chen FS, Chang CN (2003) Surf Coat Technol 173:9

Sun Y (2005) Mater Sci Eng A 404:124

Sun Y, Haruman E (2006) Vacuum 81:114

Tsujikawa M, Yoshida D, Yamauchi N, Ueda N, Sone T, Tanaka S (2005) Surf Coat Technol 200:507

Abd El-Rahamn AM, El-Hossary FM, Negm NZ, Prokert F, Richter E, Moeller W (2004) Nucl Instrum Methods Phys Res B 226:499

Abd El-Rahamn AM, El-Hossary FM, Fitz T, Negm NZ, Prokert F, Pham MT, Richter E, Moeller W (2004) Surf Coat Technol 183:268

Jenkins R, Fawcet TG, Smith DK, Visser JW, Morris MC, Frevel LK (1986) Powder Diffr 1:51

Rietveld HM (1967) Acta Crystallogr 22:151

Wiles DB, Young RA (1981) J Appl Crystallogr 14:149

Carvajal JR (2000) An introduction to the program FullProf. Lab Leon Brillouin, Saclay

Oliver WC, Pharr GM (1992) J Mater Res 7:1564

Blawert C, Kalvelage H, Mordike BL, Collins GA, Short KT, Jirásková Y, Schneeweiss O (2001) Surf Coat Technol 136:181

Fewell MP, Priest JM (2008) Surf Coat Technol 202:1802

Czerwiec T, Renevier N, Michel H (2000) Surf Coat Technol 131:267

Baranowska J, Franklin SE, Pelletier CGN (2005) Wear 259:432

Williamson DL, Davis JA, Wilbur PJ (1998) Surf Coat Technol 103–104:178

Parascandola S, Moeller W, Willianson DL (2000) Appl Phys Lett 67:2194

de Souza GB, Foerster CE, Silva SLR, Lepienski CM (2006) Mater Res 9:159

Alves C, Rodrigues JA (2000) Mat Sci Eng A 279:10

Saha R, Nix WD (2002) Acta Mater 5023:23

Zum Garh K-H (1987) Microstructure and wear of materials tribology series, vol 10. Elsevier, Amsterdam

Bushan B, Grupta BK (1991) Handbook of tribology coatings and surfaces treatments. McGraw-Hill, New York

Acknowledgement

We would like to acknowledge the Brazilian agency CNPq, for its financial support, and the Centro de Microscopia Eletrônica-UFPR.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nascimento, F.C., Lepienski, C.M., Foerster, C.E. et al. Structural, mechanical, and tribological properties of AISI 304 and AISI 316L steels submitted to nitrogen–carbon glow discharge. J Mater Sci 44, 1045–1053 (2009). https://doi.org/10.1007/s10853-008-3211-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3211-z