Abstract

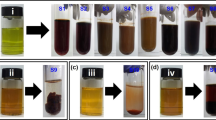

In this work, a novel method of producing maghemite (γ-Fe2O3) nanopowders has been developed, which can be performed by the direct thermal decomposition of an Fe–urea complex ([Fe(CON2H4)6](NO3)3) in a single step. The reaction mechanism, particle morphology, and the magnetic properties of the γ-Fe2O3 nanopowders have been studied by using thermogravimetric (TG), differential scanning calorimetry (DSC), fourier transformed infrared (FTIR) spectroscopy, elemental analysis, X-ray powder diffraction (XRD), transmission electron micrograph (TEM) observations, and magnetic measurements. Thermal analyses together with the results of XRD show that the formation of γ-Fe2O3 occurs at ~200 °C through a two-stage thermal decomposition of the [Fe(CON2H4)6](NO3)3 complex. The resulting iron oxide phases (i.e., γ-Fe2O3 and α-Fe2O3) are strongly dependent on the synthesis conditions of the [Fe(CON2H4)6](NO3)3. When the molar ratio of Fe(NO3)3 · 9H2O to CON2H4 that is used for the synthesis of [Fe(CON2H4)6](NO3)3 is 1:6 (i.e., molar ratio in stoichiometry), a mixed phase of γ-Fe2O3 and α-Fe2O3 is formed. When the molar ratio is 1:6.2 (i.e., using an excess CON2H4), on the other hand, a pure γ-Fe2O3 is obtained. Magnetic measurements show that resulting nanopowders exhibit a ferromagnetic characteristic and their maximum saturation magnetization increases from 47.2 to 67.4 emu/g with an increase in the molar ratio of Fe(NO3)3 · 9H2O to CON2H4 from 1:6 to 1:6.2.

Similar content being viewed by others

References

Yan ZJ, Xue DS (2008) J Mater Sci 43:771. doi:https://doi.org/10.1007/s10853-007-2046-3

Chen XH, Song HAH (2007) J Mater Sci 42:8738. doi:https://doi.org/10.1007/s10853-007-1825-1

Dhara S, Rastogi AC, Das BK (1993) J Appl Phys 74:7019

Neuberger T, Schöpf B, Hofmann H, Hofmann M, Rechenberg BV (2005) J Magn Magn Mater 293:483

Lominicki S, Dellinger B (2003) Environ Sci Technol 37:4254

Zayat M, Monte F, Morales MP, Rosa G, Guerrero H, Serna CJ, Levy D (2003) Adv Mater 15(21):1809

Grimm S, Schultz M, Barth S, Muller R (1997) J Mater Sci 32:1083. doi:https://doi.org/10.1023/A:1018598927041

Mcmichael RD, Shull RD, Swartzendruber LJ, Watson RE (1992) J Magn Magn Mater 111:29

Chen F, Xie Y, Zhao J, Lu G (2001) Chemosphere 44:1159

Apte SK, Naik SD, Sonawane RS, Kale BB (2007) J Am Ceram Soc 90:412

Prasad NK, Panda D, Singh S, Mukadam MD, Yusuf SM, Bahadur D (2005) J Appl Phys 97:10Q903

Kojima K, Miyazaki M (1997) J Sol-Gel Sci Tech 8:77

Cannas C, Concas G, Falgui A, Musinu A, Spano G, Piccaluga G (2001) J Non Cryst Solids 286:64

Solinas S, Piccaluga G, Morales MP, Serna CJ (2001) Acta Mater 49:2805

Ortega D, Garitaonandia JS, Barrera-Solano C, Bamírez-del-Solar M, Blanco E, Domínguez M (2006) J Non Cryst Solids 352:2801

Hyeon T, Lee SS, Park J, Chung Y, Na HB (2001) J Am Chem Soc 123:12798

Cheon J, Kang N-J, Lee S-M, Lee J-H, Yoon J-H, Oh SJ (2004) J Am Chem Soc 126:1950

Ravindranathan P, Patil KC (1986) J Mater Sci Lett 5:221

Li D, Wu D, Zhu J, Wang X, Lu L, Yang X (2003) J Mater Sci Lett 22:931

Yang S, Yi J-H, Son S, Jang J, Altman I, Pikhitsa P, Choi M (2003) Appl Phys Lett 83:4842

Inamdar SN, Haram SK (2006) J Nanosci Nanotechnol 6:2155

Deshpande K, Mukasyan A, Varma A (2004) Chem Mater 16:4896

Penland RB, Mizushima S, Curran C, Quagliano JV (1957) J Am Chem Soc 79:1575

Nogami M, Asuha N (1993) J Mater Sci Lett 12:1705

Woo K, Hong J, Choi S, Lee HW, Ahn JP, Kim CS, Lee SW (2004) Chem Mater 16:2814

Jing Z (2006) Mater Lett 60:2217

Morales MP, Veitemillas-Verdaguer S, Montero MI, Sema CJ, Roig A, Casas LI, Martínez B, Sandiumenge F (1999) Chem Mater 11:3058

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhao, S., Wu, H.Y., Song, L. et al. Preparation of γ-Fe2O3 nanopowders by direct thermal decomposition of Fe-urea complex: reaction mechanism and magnetic properties. J Mater Sci 44, 926–930 (2009). https://doi.org/10.1007/s10853-008-3192-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3192-y