Abstract

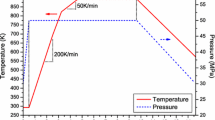

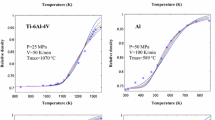

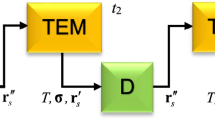

The intricate bulk and contact multiphysics of spark plasma sintering (SPS) together with the involved non-linear materials’ response make the process optimization very difficult both experimentally and computationally. The present work proposes an integrated experimental/numerical methodology, which simultaneously permits the developed SPS model to be reliably tested against experiments and to self-consistently estimate the overall set of unknown SPS contact resistances. Unique features of the proposed methodology are: (a) simulations and experiments are conducted in current control mode (SPS-CCm); (b) the SPS model couples electrothermal and displacement fields; (c) the contact multiphysics at the sliding punch/die interface is modeled during powder sintering using a moving mesh/moving boundary technique; (d) calibration and validation procedures employ both graphite compact and conductive WC powder samples. The unknown contact resistances are estimated iteratively by minimizing the deviation between predictions and on-line measurements (i.e., voltage, die surface temperature, and punch displacement) for three imposed currents (i.e., 1,900, 2,100, 2,700 A) and 20 MPa applied pressure. An excellent agreement is found between model predictions and measurements. The results show that the SPS bulk and contact multiphysics can be accurately reproduced during densification of ultrafine binderless WC powder. The results can be used to benchmark contact resistances in SPS systems applicable to graphite and conductive (WC) powder samples. The SPS bulk and contact multiphysics phenomena arising during sintering of ultrafine binderless WC powders are finally discussed. A direct correlation between sintering microstructure, sintering temperature, and heating rate is established. The developed self-consistent SPS model can be effective used as an aiding tool to design optimum SPS experiments, predict sintering microstructure, or benchmark SPS system hardware or performances.

Similar content being viewed by others

References

Munir ZA, Anselmi-Tamburini U, Ohyanagi M (2006) J Mater Sci 41:763. doi:https://doi.org/10.1007/s1085-006-6555-2

Keum YT, Jeon JH, Auh KH (2002) J Ceram Proc Res 3:195

Leuenberger G, Ludwig R, Apelian D (2002) J Non-Destr Eval 21:111

Zhang J, Zavaliangos A, Kraemer M, Groza JR (2002) In: Lawley A, Smugeresky JE, Smith L (eds) Process modeling in powder metallurgy and particulate materials: Proceedings of the 2002 international conference on process modeling powder metallurgy and particulate materials, Newport Beach, CA, pp 208–215, 28–29 October 2002

Zhang J, Zavaliangos A, Groza JR (2003) In: International conference on powder metallurgy and particulate materials, Las Vegas

Zhang J, Zavaliangos A, Groza JR (2003) In: Cornwall RG, German RM, Messing GL (eds) Proceedings of sintering 2003, Materials Research Institute, Pennsylvania State University, University Park, PA, 14–17 September 2003

Zhang J, Zavaliangos A, Groza JR (2003) P/M Sci Tech Briefs 5:5

Zhang J (2003) Numerical simulation of sintering under electric field. PhD Thesis, Drexel University, Philadelphia, PA

Anselmi-Tamburini U, Garay JE, Munir ZA, Tacca A, Maglia F, Spinolo G (2004) J Mater Res 19:3255

Zavaliangos A, Zhang J, Krammer M, Groza JR (2004) Mater Sci Eng A 379:218

Anselmi-Tamburini U, Gennari S, Garay JE, Munir ZA (2005) Mater Sci Eng A394:139

Anselmi-Tamburini U, Garay JE, Munir ZA (2005) Mater Sci Eng. A 407:24

Vanmeensel K, Laptev A, Hennicke J, Vleugels J, Van der Biest O (2005) Acta Mater 53:4379

Cincotti A, Locci AM, Orru’ R, Cao G (2007) AIChE J 53:703

Olevsky E, Froyen L (2006) Scr Mater 55:1175

Maizza G, Grasso S, Sakka Y, Noda T, Ohashi O (2007) Sci Tech Adv Mater 8:644

COMSOL Multiphyscs (2006) AC/DC Module, User’s Guide Vers.3.3a, August

Savvatimskiy AI (2005) Carbon 43:1115

Loeb AL (1954) J Am Ceram Soc 37:96

Austin JB (1941) Ceram Abstr 20:45

Sahimi M, Tsotsis TT (1999) Ind Eng Chem Res 36:3043

Willims WS (1998) JOM 50:62

Reeber RR, Wang K 1999) J Am Ceram Soc 82:129

Toyo Tanso Co. Ltd. Tokyo private communication

Holm R (1967) Electric contacts: theory and application. Springer, New York

Nishimoto K, Saida K, Tsuduki R (2001) J Jpn Inst Met 65:747

Luo X, Chung DDL (2001) J Tribol 123:683

Xie G, Ohashi O, Yamaguchi N, Wang A (2003) Metall Mater Trans A 34:2655

Bahrami M, Culham JR, Yovanovich MM (2004) J Heat Transf 126:896

Bahrami M, Culham JR, Yovanovich MM, Schneider GE (2004) J Thermophys Heat Transf 18:218

Song Q, Zhang W, Niel B (2005) Weld J 84:73

Acknowledgements

This work was supported by World Premier International Research Center Initiative (WPI Initiative), MEXT, Japan.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Maizza, G., Grasso, S. & Sakka, Y. Moving finite-element mesh model for aiding spark plasma sintering in current control mode of pure ultrafine WC powder. J Mater Sci 44, 1219–1236 (2009). https://doi.org/10.1007/s10853-008-3179-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3179-8