Abstract

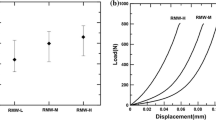

The effects of alumina (Al2O3) as an abrasive on brake friction performance and friction layers of nonmetallic brake friction materials were evaluated. Five experimental compositions containing from 0 to 14.6 vol% alumina were tested (Al2O3—0, 3.4, 5.6, 9.0, and 14.6 vol%). The experimental results indicated that alumina enhances friction coefficient and improves wear performance. The formation and development of friction layers were characterized using X-ray fluorescence spectrometry and scanning electron microscopy with energy dispersive X-ray analysis. Phenomena of baryte film and transferred iron-containing film formed on the friction surfaces were observed. Baryte films were detected on specimens containing from 0 to 5.6 vol% alumina. Iron-containing films were detected on surfaces of all alumina-containing specimens but not on the material without alumina. The role of abrasive in nonmetallic friction materials was studied in relation to formulation, friction performance, and friction surfaces.

Similar content being viewed by others

References

Lu Y, Tang CF, Zhao Y, Wright MA (2004) J Reinf Plast Compos 23:1537

Lu Y (2003) J Mater Sci 38:1081. doi:https://doi.org/10.1023/A:1022362217043

Han L, Huang L, Zhang J, Lu Y (2006) Compos Sci Tech 66:2895

Lu Y (2002) Polym Compos 23:814

Tang CF, Lu Y (2004) J Reinf Plast Compos 23:51

Lu Y (2006) Compos Sci Tech 66:591

Lu Y, Tang CF, Wright MA (2002) J Appl Polym Sci 84:2498

Ma Y, Martynková GS, Valášková M, Matějka V, Lu Y (2008) Tribol Int 41(3):166

Zhao Y, Lu Y, Wright MA (2006) Mater Design 27:833

Fan Y, Han L, Lu Y (2006) Non-metall Mines 29(5):63 (in Chinese)

Eriksson M, Bergman F, Jacobson S (2002) Wear 252:26

Eriksson M, Bergman F, Jacobson S (1999) Wear 232:163

Landolt D, Mischler S, Stemp M, Barril S (2004) Wear 256:517

Österle W, Urban I (2004) Wear 257:215

Österle W, Griepentrog M, Th Gross, Urban I (2001) Wear 251:1469

Österle W, Kloß H, Urban I, Dmitriev AI (2007) Wear 263:1189

Cho MH, Cho KH, Kim SJ, Kim DH, Jang H (2005) Tribb Lett 20(2):101

Ostermeyer GP, Muller M (2006) Trib Int 39:370

Muller M, Ostermeyer GP (2007) Trib Int 40:942

Acknowledgements

The authors acknowledge National Natural Science Foundation of China (50673012), Twaron Research Fund (Teijin Twaron GmbH, Germany, 2007), Programs of International Cooperation funded by Ministry of Education, Youth and Sports of Czech Republic 1P05ME741, and Ministry of Education, Youth and Sports of the Czech Republic (MSM 6198910016) for their financial supports.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tomášek, V., Kratošová, G., Yun, R. et al. Effects of alumina in nonmetallic brake friction materials on friction performance. J Mater Sci 44, 266–273 (2009). https://doi.org/10.1007/s10853-008-3041-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-3041-z