Abstract

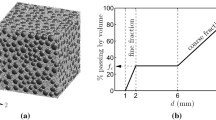

Self-formed W graded preform was produced by size segregation of weakly vibrated tungsten bimodal granular medium. The bimodal granular media bed was initially set up with larger W agglomerates placed on the bottom and with smaller agglomerates on the top of the container. During the vibro-compaction treatment the granular bed progresses through three distinguished compaction stages: percolation, diffusion like or hopping, and non-equilibrium steady state, which exhibit different packing factor and structures. Shorter vibration time results in a skeleton type of microstructure, while a graded structure was formed when the system reaches a non-equilibrium steady state. The vibrated beds were uniaxially pressed to manufacture sintered W preform with a graded interconnected porosity. High temperature sintering treatments complete the evolution of a steeper gradient in porosity predominantly through coalescence process. Electrical and elastic properties of the final materials, produced by infiltration of Cu into the sintered W preforms, are strongly influenced by the W microstructural evolution. It has been shown that the optimal microstructure for electrical properties consists of a highly 3D interconnected Cu phase (skeleton type of microstructure), while the graded structure exhibits higher E-modulus. This work was undertaken to better understand the nature of the graded structure and to study the relationship between the self-formed microstructure types, electrical and elastic materials properties.

Similar content being viewed by others

References

Jaeger HE, Nagel SR (1992) Science 255:1523

Rosato A, Strandburg KJ, Prinz F, Swendsen RH (1987) Phys Rev Lett 58(10):1038

Hsiau SS, Chen CH (2000) Powder Technol 111:210

Fiscina JE, Janković Ilić D, Mückluch F (2004) Granul Matter 5:207

Müller E, Drašar Č, Schilz J, Kaysser WA (2003) Mater Sci Eng A 362:17

Weber L, Dorn J, Mortensen A (2003) Acta Mater 51:3199

Horsekor S, Koka A, Wegner A, Arnold W (2000) In: Thompson DO (ed) Review of quantitative nondestructive evolution vol 19 (Chimentide), p 1367

Rohdes M, Takeuchi S, Liffman K, Muniandy K (2003) Granul Matter 5:107

Hong DC, Quinn PV, Ludvig S (2001) Phys Rev Lett 86:3423

Janković Ilić D, Fiscina J, Gonzalez-Oliver CJR, Ilić N, Mücklich F (2007) Adv Eng Mater 9(5):542

Hayakawa H, Hong DC (1997) Phys Rev Lett 78(14):2764

Fiscina JE, Caceres MO (2005) Phys Rev Lett 95:108003

Breu APJ, Ensner H-M, Kruelle CA, Rehberg I (2003) Phys Rev Lett 90:014302

Nicodemi M, Coniglio A, Herrmann HJ (1997) Phys Rev E 55(4):3962

Reynolds O (1885) Philos Mag 20:469

Kingery WD, Francois B (1967) In: Kuczynski GC, Hooten HA, Gilbon GN (eds) Sintering and related phenomena. Gordon and Breach, New York, p 471

Mehta A, Barker GC (1991) Phys Rev Lett 67:394

D’ Anna G, Gremaud G (2001) Europhys Lett 54(5):599

Lassner E, Schubert W-D (1999) In: Tungsten: properties, chemistry, technology of the element, alloys and chemical compounds. Kluwer Academics, NY, p 279

Janković Ilić D (2007) PhD thesis, Saarland University

Acknowledgements

D. Janković Ilić acknowledges the financial support of DFG under the project “Gradient materials”—project number: Mu 959 / 5. and DFG Graduiertenkollegs: IIIGK-GRK 232/2. J.E. Fiscina greatly acknowledges the support of Alexander von Humbolt Foundation. The research work of F.Mücklich was supported by the Alfried Krupp Prize for Young University Teachers awarded by the Krupp Foundation. The authors greatly acknowledge the help of A. Lasagni (Saarland University, Saarbrücken) and A. Koka (Fraunhofer Institute for Non-destructive Testing, Saarbrücken).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Janković Ilić, D., Fiscina, J., González-Oliver, C.J.R. et al. Electrical and elastic properties of Cu-W graded material produced by vibro compaction. J Mater Sci 43, 6777–6783 (2008). https://doi.org/10.1007/s10853-008-2941-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2941-2