Abstract

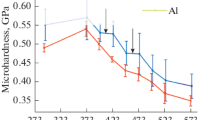

The effect of post-process deformation on the mechanical properties of nanostructured aluminum (99.2% purity) has been investigated by cold rolling of samples which have been processed by accumulative roll bonding (ARB) to a strain of εvM = 4.8. Samples have been cold rolled to 10, 15, and 50% reductions and ultimate tensile strength (UTS), yield stress and elongation have been determined by tensile testing at room temperature. The mechanical testing shows that cold rolling to low strains (10% and 15%) leads to softening and increase in elongation compared to the as-processed ARB material. In contrary, cold rolling to large strain (50%) results in significant strengthening. This leads to the suggestion of a transition strain within the range of 25–35% reduction by rolling. The microstructural evolution during post-process deformation has been followed by transmission electron microscopy showing a significant change in the dislocation structure when the strain is increased. Based on the experimental observations the mechanical behavior is related to the structural changes focusing on the characteristics of the dislocation structure present between the narrowly spaced lamellar boundaries in the deformed structure.

Similar content being viewed by others

References

Hughes DA, Hansen N (2000) Acta Mater 48:2985

Liu Q, Huang X, Lloyd DJ, Hansen N (2002) Acta Mater 53:3789

Mishin OV, Juul Jensen D, Hansen N (2003) Mater Sci Eng A 342:320

Cabibbo M, Blum W, Evangelista E, Kassner ME, Meyers MA (2007) Metall Mater Trans A 39A:181

Wu XL, Ma E (2006) Appl Phys Lett 88:231911

Zhao YH, Zhu YT, Liao XZ, Horita Z, Langdon TG (2006) Appl Phys Lett 89:121906

Zhao YH, Bingert JF, Liao XZ, Cui BZ, Sergueeva AV, Mukherjee AK, Valiev RZ, Langdon TG, Zhu YT (2006) Adv Mater 18:2949

Huang X (2007) J Mater Sci 42:1577. doi:https://doi.org/10.1007/s10853-006-0988-5

Zhao YH, Bingert JF, Zhu YT, Liao XZ, Valiev RZ, Horita Z, Langdon TG, Zhou YZ, Lavernia EJ (2008) Appl Phys Lett 92:081903

Hansen N (2004) Scr Mater 51:801

Hansen N, Huang X, Hughes DA (2001) Mater Sci Eng A 317:3

Huang X, Kamikawa N, Hansen N (2008) Mater Sci Eng. doi:https://doi.org/10.1016/j.msea.2007.04.131

Ma E (2003) Scr Mater 49:663

Huang X, Hansen N, Tsuji N (2006) Science 312:249

Huang X, Kamikawa N, Hansen N (2008) Mater Sci Eng 483–484:102

Kamikawa N, Sakai T, Tsuji N (2007) Acta Mater 55:5873

Winther G, Huang X, Godfrey A, Hansen N (2004) Acta Mater 52:4437

Liu Q (1995) Ultramicroscopy 60:81

Acknowledgement

We acknowledge the Danish National Research Foundation for supporting the Center for Fundamental Research: Metal Structures in Four Dimensions, within which this work was performed.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Huang, X., Kamikawa, N. & Hansen, N. Property optimization of nanostructured ARB-processed Al by post-process deformation. J Mater Sci 43, 7397–7402 (2008). https://doi.org/10.1007/s10853-008-2873-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2873-x