Abstract

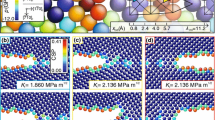

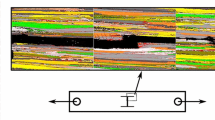

Intergranular fracture is a dominant mode of failure in ultrafine grained materials. In the present study, the atomistic mechanisms of grain-boundary debonding during intergranular fracture in aluminum are modeled using a coupled molecular dynamics—finite element simulation. Using a statistical mechanics approach, a cohesive-zone law in the form of a traction–displacement constitutive relationship, characterizing the load transfer across the plane of a growing edge crack, is extracted from atomistic simulations and then recast in a form suitable for inclusion within a continuum finite element model. The cohesive-zone law derived by the presented technique is free of finite size effects and is statistically representative for describing the interfacial debonding of a grain boundary (GB) interface examined at atomic length scales. By incorporating the cohesive-zone law in cohesive-zone finite elements, the debonding of a GB interface can be simulated in a coupled continuum–atomistic model, in which a crack starts in the continuum environment, smoothly penetrates the continuum–atomistic interface, and continues its propagation in the atomistic environment. This study is a step toward relating atomistically derived decohesion laws to macroscopic predictions of fracture and constructing multiscale models for nanocrystalline and ultrafine grained materials.

Similar content being viewed by others

References

Yamakov V, Phillips DR, Saether E, Glaessgen EH (2007) In: Bozzolo GH, Noebe RD, Abel P (eds) Applied computational materials modeling: theory, experiment, and simulation. Springer. ISBN 978-0-387-23117-4

Glaessgen E, Saether E, Phillips D, Yamakov V (2006) 47th AIAA/ASME/ASCE/AHS/ASC structures, structural dynamics and materials conference and exhibit, Newport, RI, May 1–4, 2006

Dugdale DS (1960) J Mech Phys Solids 8:100. doi:https://doi.org/10.1016/0022-5096(60)90013-2

Barenblatt GI (1962) Adv Appl Mech 7:55

Yamakov V, Saether E, Phillips DR, Glaessgen EH (2006) J Mech Phys Solids 54:1899. doi:https://doi.org/10.1016/j.jmps.2006.03.004

Tvergaard V, Hutchinson JW (1996) Int J Solids Struct 33:3297. doi:https://doi.org/10.1016/0020-7683(95)00261-8

Beer G (1985) Int J Numer Methods Eng 21:585. doi:https://doi.org/10.1002/nme.1620210402

Gall K, Horstemeyer MF, Van Schilfgaarde M, Baskes MI (2000) J Mech Phys Solids 48:2183. doi:https://doi.org/10.1016/S0022-5096(99)00086-1

Komanduri R, Chandrasekaran N, Raff LM (2001) Int J Mech Sci 43:2237. doi:https://doi.org/10.1016/S0020-7403(01)00043-1

Spearot D, Jacob KI, Mcdowell DL (2004) Mech Mater 36:825

Raynolds JE, Smith JR, Zhao G-L, Srolovitz DJ (1996) Phys Rev B 53:13883. doi:https://doi.org/10.1103/PhysRevB.53.13883

Mishin Y, Farkas D, Mehl MJ, Papaconstantopoulos DA (1999) Phys Rev B 59:3393. doi:https://doi.org/10.1103/PhysRevB.59.3393

Saether E, Yamakov V, Glaessgen E (2007) 49th AIAA/ASME/ASCE/AHS/ASC structures, structural dynamics and materials conference

Saether E, Yamakov V, Glaessgen E (submitted) Int J Numer Meth Eng

Cleri F (2001) Phys Rev B 65:014107. doi:https://doi.org/10.1103/PhysRevB.65.014107

Parrinello M, Rahman A (1981) J Appl Phys 52:7182. doi:https://doi.org/10.1063/1.328693

Nose S (1984) J Chem Phys 81:511. doi:https://doi.org/10.1063/1.447334

Yamakov V, Saether E, Phillips DR, Glaessgen EH (2007) J Mater Sci 42:1466. doi:https://doi.org/10.1007/s10853-006-1176-3

Yamakov V, Saether E, Phillips DR, Glaessgen EH (2005) Phys Rev Lett 95:015502. doi:https://doi.org/10.1103/PhysRevLett.95.015502

Murakami Y (ed) (1988) Stress intensity factors handbook, vol 1. Pergamon Press, New York

Klimontovich YL (1995) Statistical theory of open systems, vol 1. Kluwer Academic Publishers, Netherlands

Acknowledgement

V. Yamakov is sponsored through cooperative agreement NCC-1-02043 with the National Institute of Aerospace.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yamakov, V., Saether, E. & Glaessgen, E.H. Multiscale modeling of intergranular fracture in aluminum: constitutive relation for interface debonding. J Mater Sci 43, 7488–7494 (2008). https://doi.org/10.1007/s10853-008-2823-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2823-7