Abstract

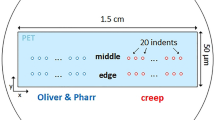

A series of PMR-15 resin specimens were isothermally aged at 288, 316, and 343 °C over a range of time. For PMR-15 aged at 288 °C, the samples were also subjected to different aging environments including: ambient air, dry air, inert (argon), and pressurized air (0.414 MPa). Nanoindentation was performed to characterize localized mechanical properties as well as the development and growth of the oxidative layer. The measured increase in stiffness in the specimen surface oxidation layer is a manifestation of the chemical changes in the polymer occurring during oxidation. The average elastic modulus in the oxidized region is relatively insensitive to variations in aging temperature, time, and the environments. The thickness of the oxidative layer is observed to increase in the early stages of oxidation and the oxidation process eventually approaches an auto-retardation state. Aging under elevated pressure increases the thickness growth rate of the oxidation layer, while there is no significant difference in growth rate for specimens aged in dry air versus those aged in ambient air. It is shown that the measured average thickness of the oxidation layer and the transition region determined by the nanoindenter is in good agreement with optical microscopy measurements for all conditions considered.

Similar content being viewed by others

References

Bowles KJ, Papadopoulos DS, Inghram LL, McCorkle LS, Klan OV (2001) NASA/TM-2001-210602

Tsuji LC, McManus HL, Bowles KJ (1998) NASA Technical Report -208487:1

Régnier N, Berriot J, Lafontaine E, Mortaigne B (2001) Polym Degrad Stab 73:485

Meadors MA, Lowell CE, Cavano PJ, Herrera-Fierro P (1996) High Perform Polym 8:363

Xie W, Pan WP, Chuang KC (2001) Thermochim Acta 367–368:143

Dole P, Chauchard J (1995) Polym Degrad Stab 47:441

Briscoe BJ, Fiori L, Pelillo E (1998) J Phys D Appl Phys 31:2395

Raghavan D, Gu X, Nguyen T, VanLandingham M, Karim A (2000) Macromolecules 33:2573

Gillen KT, Clough RL, Quintana CA (1987) Polym Degrad Stab 17:31

Gregory JR, Spearing SM (2005) Compos Sci Technol 65:595

Parvatareddy H, Wang JZ, Lesko JJ, Dillard DA, Reifsnider KL (1996) J Compos Mater 30(2):210

Gillen KT, Terrill ER, Winter RM (2001) Rubber Chem Technol 74(3):428

Oliver WC, Pharr GM (1992) J Mater Res 7(6):1564

Pharr GM, Bolshakov A (2002) J Mater Res 17(10):2660

Hay JL, Pharr GM (2000) ASM handbook. ASM International, Materials Park, p 232

Pharr GM (1998) Mater Sci Eng A253:151

Johnson LL, Eby RK, Meador MAB (2003) Polymer 44:187

Ripberger E, Tandon GP, Schoeppner GA (2004) In: Proceedings of the SAMPE 2004 symposium/exhibition, Long Beach, CA, 16–20 May

Putthanarat S, Tandon GP, Schoeppner GA (2007) Polym Degrad Stab 92:2110

Tandon GP, Pochiraju KV, Schoeppner GA (2006) Polym Degrad Stab 91(8):1861

Schoeppner GA, Tandon GP, Pochiraju KV (2007) In: Kwon Y, Allen D, Talreja, R (eds) Multiscale modeling and simulation of composite materials and structures. Springer, New York

Oliver WC, Pharr GM (2004) J Mater Res 19(1):3

McElhaney KW, Vlassak JJ, Nix WD (1998) J Mater Res 13(5):1300

Li X, Bhushan B (2002) Mater Charact 48:11

Mencik M, Swain MV (1995) J Mater Res 10(6):1491

Thorp KE (2000) PhD Dissertation, University of Dayton, Dayton

Acknowledgements

This work is supported by the Air Force Office of Scientific Research under the Materials Engineering for Affordable New Systems (MEANS-II) program sponsored by Dr. Charles Lee.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Putthanarat, S., Tandon, G.P. & Schoeppner, G.A. Influence of aging temperature, time, and environment on thermo-oxidative behavior of PMR-15: nanomechanical characterization. J Mater Sci 43, 6714–6723 (2008). https://doi.org/10.1007/s10853-008-2800-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2800-1