Abstract

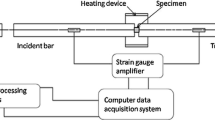

In this work, we have processed commercial purity tungsten (W) via different routes of equal-channel angular extrusion (ECAE) at temperatures as low as 600 °C. We have systematically evaluated the quasi-static and dynamic compressive behaviors of the processed W. Quasi-static compression tests were performed using an MTS hydro-servo system at room temperature. It is observed that samples ECAE processed at 800 °C show higher yield and flow stresses than those processed at other temperatures; no obvious strain hardening is observed in the quasi-static stress–strain curves. Quasi-static strain rate jump tests show that the strain rate sensitivity of ECAE W is in the range of 0.02 to 0.03, smaller than that of coarse-grained W. Uni-axial dynamic compressive tests were performed using the Kolsky bar (or split-Hopkinson pressure bar, SHPB) system. Post-loading SEM observations revealed that under dynamic compression, the competition between cracking at pre-existing extrinsic surface defects, grain boundaries, and uniform plastic deformation of the individual grains control the overall plastic deformation of the ECAE W. The existence of flow softening under dynamic loading has been established for all of the ECAE W specimens.

Similar content being viewed by others

References

Krasko GL (1993–1994) Int J Refract Met Hard Mater 12:251

Dummer T, Lasalvia JC, Ravichandran G, Meyers MA (1998) Acta Mater 46:6267. doi:https://doi.org/10.1016/S1359-6454(98)00255-9

Lennon AM, Ramesh KT (2000) Mater Sci Eng A 276:9. doi:https://doi.org/10.1016/S0921-5093(99)00517-1

Wei Q, Jiao T, Ramesh KT, Ma E, Kecskes LJ, Magness L et al (2006) Acta Mater 54:77. doi:https://doi.org/10.1016/j.actamat.2005.08.031

Kecskes LJ, Cho KC, Dowding RJ, Schuster BE, Valiev RZ, Wei Q (2007) Mater Sci Eng A 467:33. doi:https://doi.org/10.1016/j.msea.2007.02.099

Lu K (2008) Int Mater Rev 53:21. doi:https://doi.org/10.1179/174328008X254358

Valiev RZ, Estrin Y, Horita Z, Langdon TG, Zehetbauer M, Zhu YT (2006) JOM-US 58:33

Wei Q, Ramesh KT, Kecskes LJ, Mathaudhu SN, Hartwig KT (2008) Mater Sci Forum 579:75

Bechtold JH (1956) J Met Trans AIME 206:142

Farrell K, Schaffhauser AC, Stiegler JO (1967) J Less Common Met 13:141. doi:https://doi.org/10.1016/0022-5088(67)90177-4

Wei Q, Zhang H, Schuster BE, Ramesh KT, Valiev RZ, Kecskes LJ et al (2006) Acta Mater 54:4079. doi:https://doi.org/10.1016/j.actamat.2006.05.005

Wei Q, Ramesh KT, Ma E, Kesckes LJ, Dowding RJ, Kazykhanov VU et al (2005) Appl Phys Lett 86:101907. doi:https://doi.org/10.1063/1.1875754

Barber RE, Dudo T, Yasskin PB, Hartwig KT (2004) Scripta Mater 51:373. doi:https://doi.org/10.1016/j.scriptamat.2004.05.022

Follansbee PS (1985) In ASM metals handbook. American Society of Metals. p 190

Hall EO (1951) P Phys Soc B 64:747

Petch NJ (1953) J Iron Steel I 174:25

Wei Q (2007) J Mater Sci 42:1709. doi:https://doi.org/10.1007/s10853-006-0700-9

Wei Q, Cheng S, Ramesh KT, Ma E (2004) Mater Sci Eng A 381:71. doi:https://doi.org/10.1016/j.msea.2004.03.064

Wei Q, Kecskes LJ (2008) Mater Sci Eng A. doi:https://doi.org/10.1016/j.msea.2008.01.013

Acknowledgements

This work has been supported by the U.S. Army Research Laboratory under contract # W911QX-06-C-0124. The authors would like to thank Ms. Xueran Liu (University of North Carolina at Charlotte) for assistance with SEM operations.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Pan, Z., Guo, Y.Z., Mathaudhu, S.N. et al. Quasi-static and dynamic mechanical properties of commercial-purity tungsten processed by ECAE at low temperatures. J Mater Sci 43, 7379–7384 (2008). https://doi.org/10.1007/s10853-008-2788-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-008-2788-6