Abstract

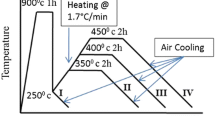

The present work has been taken up to study the influence of microstructure on the formation of martensite in austempered ductile iron. Ductile iron containing 1.5 wt.% nickel and 0.3 wt.% molybdenum was subjected to two types of austempering treatments. In the first, called as conventional austempering, the samples were austempered for 2 h at 300, 350 or 400 °C. In the second treatment, called as stepped austempering, the samples were initially austempered at 300 °C for 10, 20, 30, 45 or 60 min. These were subsequently austempered for 2 h at 400 °C. Tensile tests revealed considerable variation in the strain-hardening behaviour of the samples with different heat treatments. In the case of samples subjected to conventional austempering, it was found that strain-hardening exponent increased with increasing austempering temperature. In the case of samples subjected to stepped austempering, increased strain hardening was observed in samples subjected to short periods of first step austempering. Study of the microstructures revealed that increased strain hardening was associated with the formation of strain-induced martensite. There was a greater propensity for the formation of strain-induced martensite in the samples containing more of blocky austenite. Retained austenite in the form of fine films between sheaths of ferrite was relatively more stable. Studies revealed that the morphology, size and carbon content of the retained austenite were important parameters controlling their tendency to transform to martensite.

Similar content being viewed by others

References

Johansson M (1977) AFS Trans 85:117

Gundalach RB, Janowak JF (1983) AFS Trans 91:377

Rouns TN, Rundman KB, Moore DM (1984) AFS Trans 92:815

Gundalach RB, Janowak JF (1986) In: Proceedings of the 2nd International Conference on Austempered ductile iron, Ann Arbor, MI, USA, March. ASME Gear Research Institute, p 23

Arnzabal J, Gutierrez I, Rodriguez-Ibabe JM, Urcola JJ (1992) Mater Sci Technol 8:263

Timokhina IB, Hodgson PD, Pereloma EV (2004) Metall Mater Trans A 35A:2331

Tommita Y (1995) Mater Sci 30:105

Reisner G, Werner EA, Kerschbhaummaur P, Papst I, Fischer FD (1997) J Met 49(9):62

De Meyer M, Vanderschueren D, De Cooman BC (1999) Iron Steel Inst Jpn Int 39(8):813

Bai DQ, Di Chiro A, Yue S (1998) Mater Sci Forum 284–286:253

Chen HC, Era H, Shimizu M (1989) Metal Trans A 20A:437

Miihkinen VTT, Edmonds DV (1987) Mater Sci Technol 3:422

Takahashi M, Bhadeshia HKDH (1991) Mater Trans JIM 32:689

Wang J, Van Der Zwaag S (2001) Wire 50:1527

Tsukatani I, Hashimoto S, Inoue T (1991) Iron Steel Inst Jpn Int 31(9):992

Cullity BD (1974) Elements of x-ray diffraction. Addison-Wesley, Reading, MA, p 411

Roberts CS (1953) Trans AIME 197:203

Prasad Rao P, Putatunda SK (1998) Metall Mater Trans A 29A:3005

Rundman KB, Klug RC (1982) AFS Trans 90:499

Voigt RC, Loper CR (1984) In: Proceedings of the 1st International Conference on austempered ductile iron. ASM, Metals Park, OH, p 83

Hollomon TH (1945) Trans AIME 162:268

Acknowledgement

This work was financially supported by the Council of Scientific and Industrial Research, New Delhi, India.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Daber, S., Prasad Rao, P. Formation of strain-induced martensite in austempered ductile iron. J Mater Sci 43, 357–367 (2008). https://doi.org/10.1007/s10853-007-2258-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-2258-6