Abstract

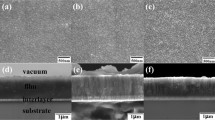

Hydrogenated carbon nitride (a-CN x H films) was deposited on n-type single-crystal Si (100) by direct current radio frequency plasma-enhanced chemical vapor deposition (DC-RF-PECVD), under the working pressure of 5.0–17.0 Pa, using the CH4 and N2 as feedstock. The composition and surface morphology of the a-CN x H films were characterized by means of Raman spectroscopy and atomic force microscopy, while the Young’s modulus, elastic recovery, adhesion strength, and tribological properties were evaluated using nano-indentation, scratch test and friction test system. It was found that the surface roughness and Raman spectra peak intensity ratio I D/I G of the films increased with the increase of working pressure, while the Young’s modulus, elastic recovery and adhesion strength of the films significantly decreased. Moreover, the tribological properties of the films also varied with the working pressure. The wear life sharply increased with the increase of working pressure from 5.0 Pa to 7.5 Pa, further, an increase in the deposition pressure led to a gradual decrease in the wear life, consequently, the a-CN x H film deposited at 7.5 Pa exhibited the longest wear life. The deposition pressure seemed to have slight effect on the average friction coefficients, whereas the surface roughness and adhesion strength have deteriorated with increasing deposition pressure.

Similar content being viewed by others

References

Liu AY, Cohen ML (1989) Science 245:841

Liu AY, Cohen ML (1990) Phys Rev B 41:10727

Liu AY, Wentzcovitch RM (1994) Phys Rev B 50:10362

Jiang LD, Fitzgerald AG, Rose MJ (2000) Appl Surf Sci 158:340

Fernandez A, Ternandez-Ramos C, Sanchez-Lopez JC (2003) Surf Coat Technol 163–164:527

López S, Dunlop HM, Benmalek M, Tourillon G, Wong M-S, Sproul WD (1997) Surf Interface Anal 25:315

Okada T, Yamada S, Takeuchi Y, Wada T (1995) J Appl Phys 78:7416

Ogata K, Chubaci JFD, Fujimoto F (1994) J Appl Phys 76:3791

Meskinis S, Andrulevicius M, Kopustinskas V, Tamulevicius S (2005) Appl Surf Sci 249:295

Boyd KJ, Marton D, Todorov SS, Al-Bayati AH, Kulik J, Zuhr RA, Rabdais JW (1995) J Vac Sci Technol A 13:2110

Bhattacharyya S, Vallee C, Cardinaud C (1999) J Appl Phys 85:2162

Égerházi L, Geretovszky Zs, Szörényi T (2005) Appl Surf Sci 247:182

Szörényi T, Fogarassy E (2003) Appl Surf Sci 208–209:502

Rusop M, Omer AMM, Adhikari S, Adhikary S, Uchida H, Soga T, Jimbo T, Umeno M (2005) Diam Relat Mater 14:975

Motta EF, Pereyra I (2004) J Non-Cryst Solids 338–340:525

Uddin MN, Fouad OA, Yamazato M, Nagano M (2005) Appl Surf Sci 240:120

Durand-Drouhin O, Benlahsen M, Clin M, Zellama K (2004) Diam Relat Mater 13:1854

Cheng YH, Sun ZH, Tay BK, Lau SP, Qiao XL, Chen JG, Wu YP, Xie CS, Wang YQ, Xu DS, Mo SB, Sun YB (2001) Appl Surf Sci 182:33

Takadoum J, Rauch JY, Cattenot JM, Martin N (2003) Surf Coat Technol 174–175:427

Li HX, Xu T, Chen JM, Zhou HD, Liu HW (2003) J Phys D: Appl Phys 36:3183

Hao JY, Xu T, Liu WM (2005) J Non-Cryst Solids 351:3671

Hao JY, Xu T, Liu WM (2005) Mater Sci Eng A 408:297

Schwan J, Ulrich S, Batori V, Ehrhardt H, Silva SRP (1996) J Appl Phys 80:440

Ferrari AC, Robertson J (2000) Phys Rev B 61:14095

Ferrari AC, Rodil SE, Robertson J (2003) Phys Rev B 67:155306

Shiao J, Hoffman RW (1996) Thin Solid Films 283:145

Bhattacharyya S, Cardinard C, Turban G (1998) J Appl Phys 83:4491

Sheeja D, Tay BK, Lau SP, Shi X (2001) Wear 249:433

Chowdhury S, Laugier MT, Rahman IZ (2004) Diam Relat Mater 13:1543

Pharr GM (1998) Mater Sci Eng A 253:151

Chowdhury AKMS, Cameron DC, Hashmi MSJ (1999) Surf Coat Technol 116–119:46

Wu W, Hon M (1999) Thin Solid Films 345:200

Broitman E, Hellgren N, Wänstrand O, Johansson MP, Berlind T, Sjöström H, Sundgren JE, Larsson M, Hultman L (2001) Wear 248:55

Sánchez-López JC, Belin M, Donnet C, Quirós C, Elizalde E (2002) Surf Coat Technol 160:138

Acknowledgements

The authors are grateful to the National Natural Science Foundation of China (Grant No. 50405040 and No. 50432020), “973” program of China (Grant No. 2007CB607601), and the Innovative Group Foundation from NSFC (Grant No. 50421502) for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ding, J., Hao, J., Xue, Q. et al. Effect of deposition pressure on the adhesion and tribological properties of a-CN x H films prepared by DC-RF-PECVD. J Mater Sci 43, 645–651 (2008). https://doi.org/10.1007/s10853-007-2149-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-007-2149-x